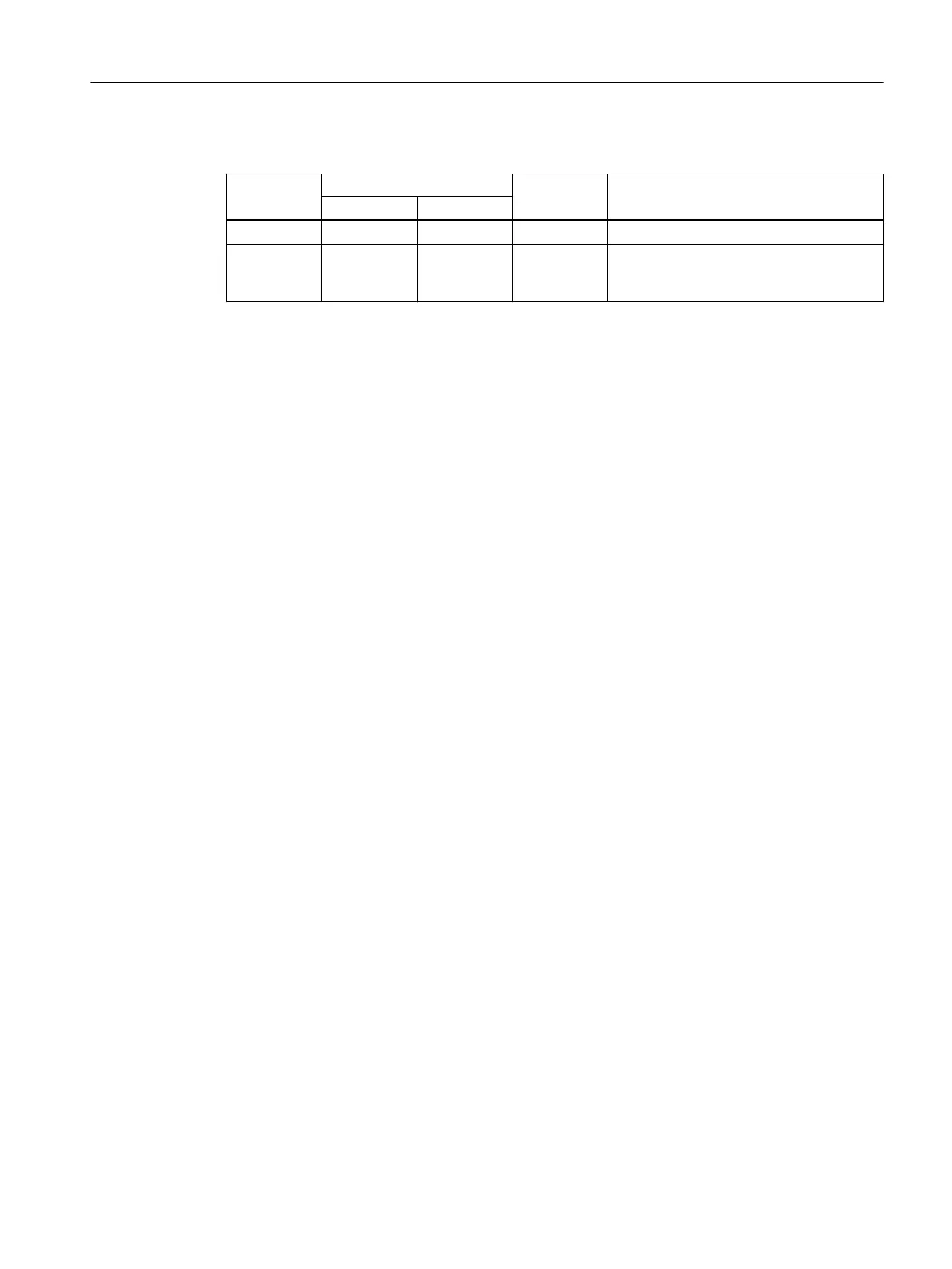

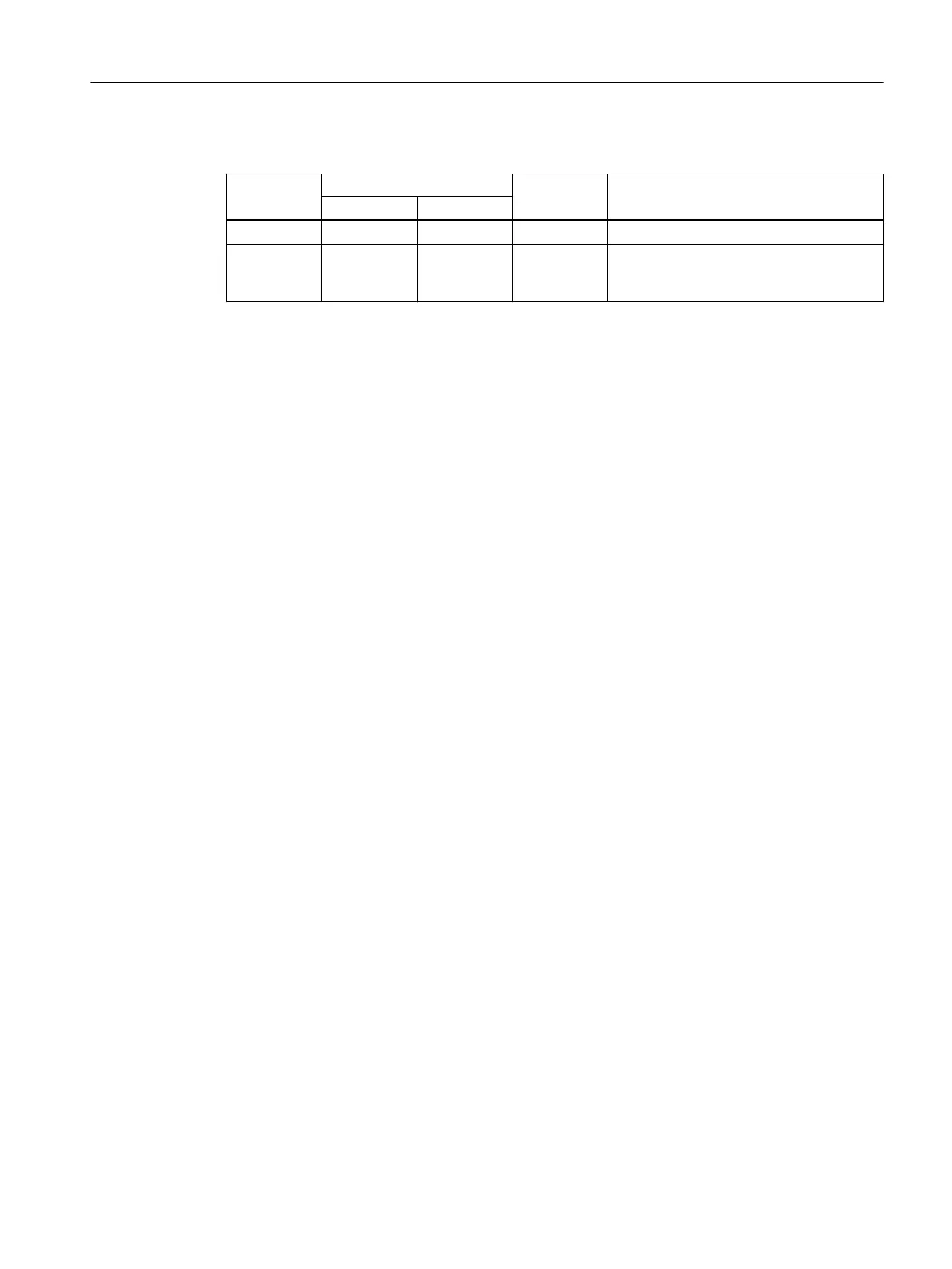

Example as a complete step

Acknowledg‐

ment step

Transfer step Acknowledg‐

ment status

Comment

New tool old tool

1 0 0 3 "Cancel order" command.

2 2 0 1 Prepare Tool: The tool is taken from the

magazine (changing point) and placed in‐

to gripper 1.

Acknowledgment is given by setting the corresponding bits in the user interface:

● DB40xx for loading/unloading / relocating or positioning the magazine

● DB42xx for "prepare tool change" and "execute tool change"

After processing, the acknowledgment bit is reset one PLC cycle by the PLC firmware.

In the same data block where the acknowledgments have taken place, for a PLC cycle the

feedback message

is output in bit 100.0 (acknowledgment OK), or as a static signal in bit 100.1

(acknowledgment error); the error status is output in byte 104 for an acknowledgment error,

and in bytes DBB108 to DBB111 the acknowledgment bits last set are output. The user can

use these bits to see which acknowledgment step triggered the error. If the PLC user program

incorrectly set multiple acknowledgment bits, these are also entered one-to-one in the map.

Resetting of the error status occurs when the user acknowledges the error in DB40xx.DBX9.0

or DB42xx.DBX9.0.

9.4.6 Adjust the PLC user program

Adjust the PLC user program

The control of mechanical processes, monitoring and prevention of potential collisions and the

acknowledgment of tool position changes are the task of the PLC user program.

See also

In the PLC project on the Toolbox CD you can find examples of transfer steps and their

acknowledgments, for a turning machine with a circular magazine and a milling machine with

a chain magazine and dual gripper:

● Application example for milling machine (Page 316)

● Application example for turning machine (Page 304)

These blocks are function examples for the acknowledgment of different tool management

jobs.

Acknowledging jobs

Many tool movements or tool management jobs can be directly acknowledged using total

acknowledgment at bit 0.0 of the interface, without previous intermediate acknowledgment.

Tool management

9.4 PLC Program Blocks

CNC commissioning

Commissioning Manual, 10/2015, 6FC5397-3DP40-5BA3 293

Loading...

Loading...