7.2 Interfaces to the operating software

Overview

To process these service/maintenance tasks, you have the following options:

●

Managing the data in the PLC user program using the programming tool.

●

Creating the maintenance tasks via an XML interface.

Using this segmentation, inconsistencies between the PLC block and the XML scripts are

avoided if the PLC block is changed in the PLC user program via the programming tool or as

a result of a commissioning archive.

Configuration

You can configure up to 32 maintenance tasks. The following columns are shown in the

configuring mode:

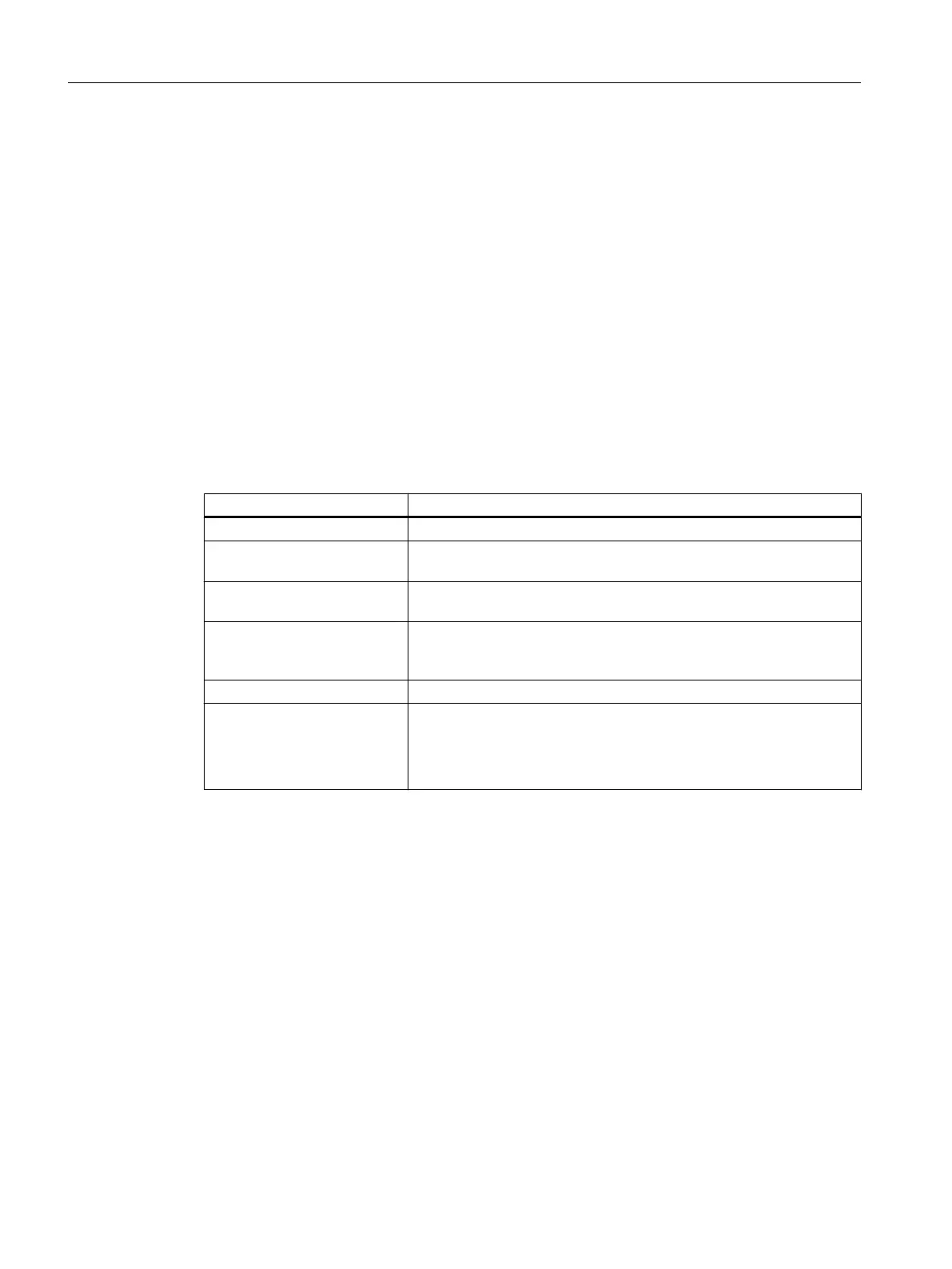

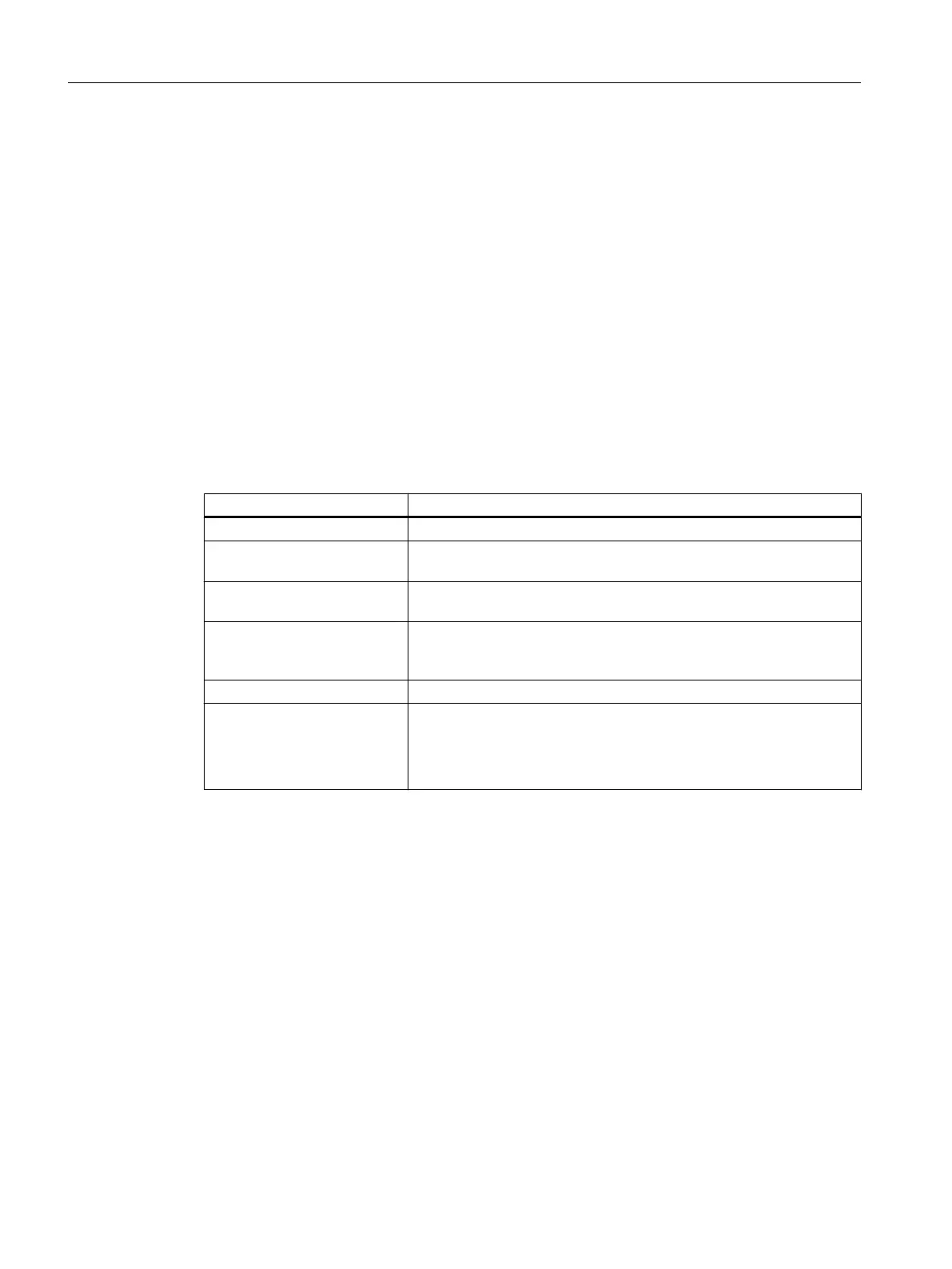

Designation of the column

Meaning

Maintenance task Name of the maintenance task

Interval [h] Maximum time until the next maintenance in hours; if this value ≠ 0,

this data set is accepted by the PLC as a valid maintenance task.

1st warning [h] Time

in hours after which the first warning is displayed; this value must

be less than that of the interval.

Number of warnings Number of warnings that are output by the PLC before the PLC sets

the

alarm bit for

the last time after the interval has expired (remaining

time == 0).

Remaining time [h] Time until the interval expires in hours.

Status

● A green check mark indicates that the time up to the next

maintenance is still running.

●

A red clock symbol indicates that there is a maintenance task to

be performed.

The dialog is called with different contents depending on the access level.

Configuration mode

Access level 2: Service

Maintenance tasks can be

created, changed and also deleted in this mode. The maintenance

tasks can also be acknowledged. All columns are visible. Navigation between the columns is

with <Tab> or <Key Left/Right>.

Service Planner

7.2 Interfaces to the operating software

CNC commissioning

230 Commissioning Manual, 10/2015, 6FC5397-3DP40-5BA3

Loading...

Loading...