Swiveling in the JOG mode

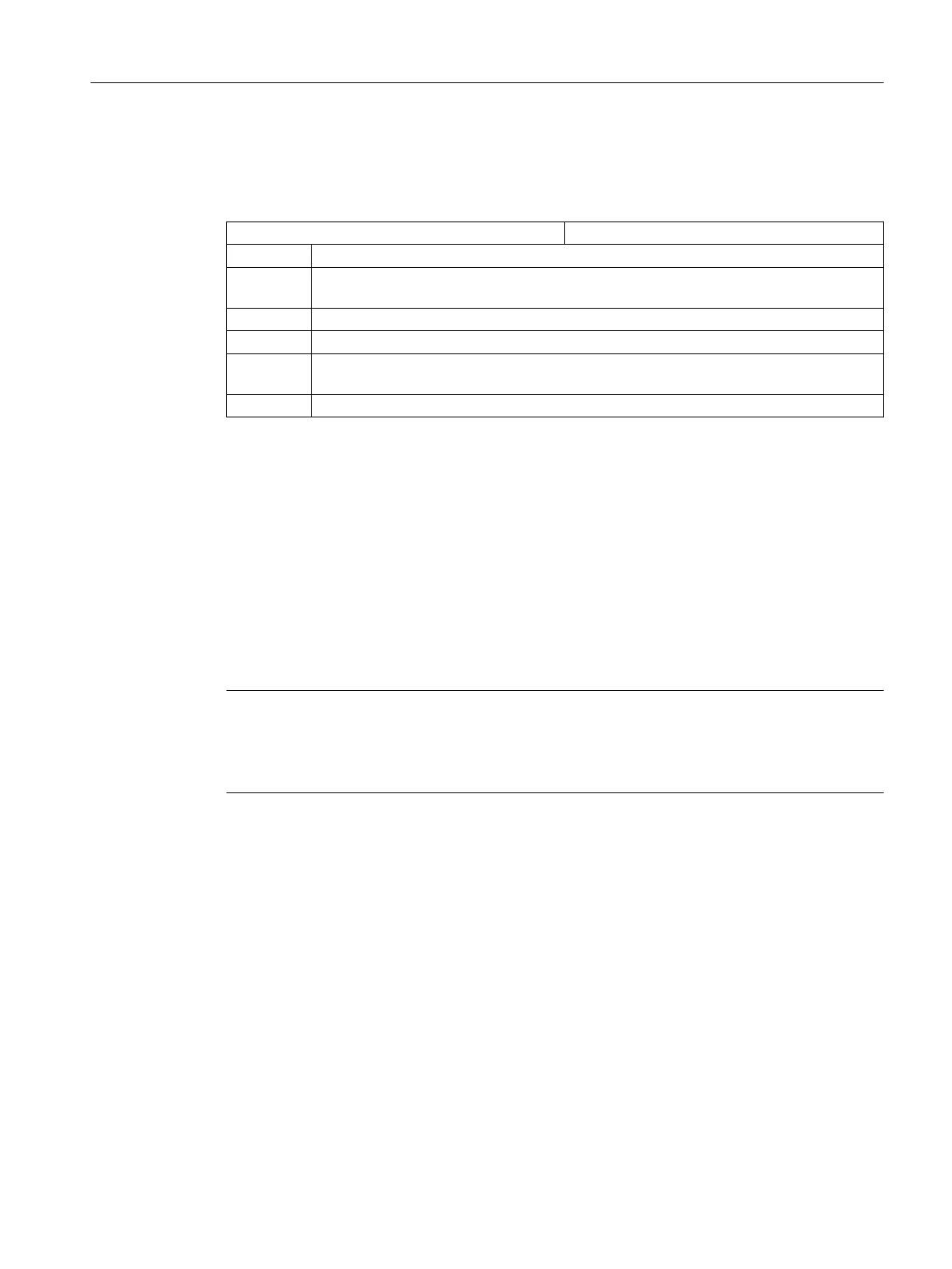

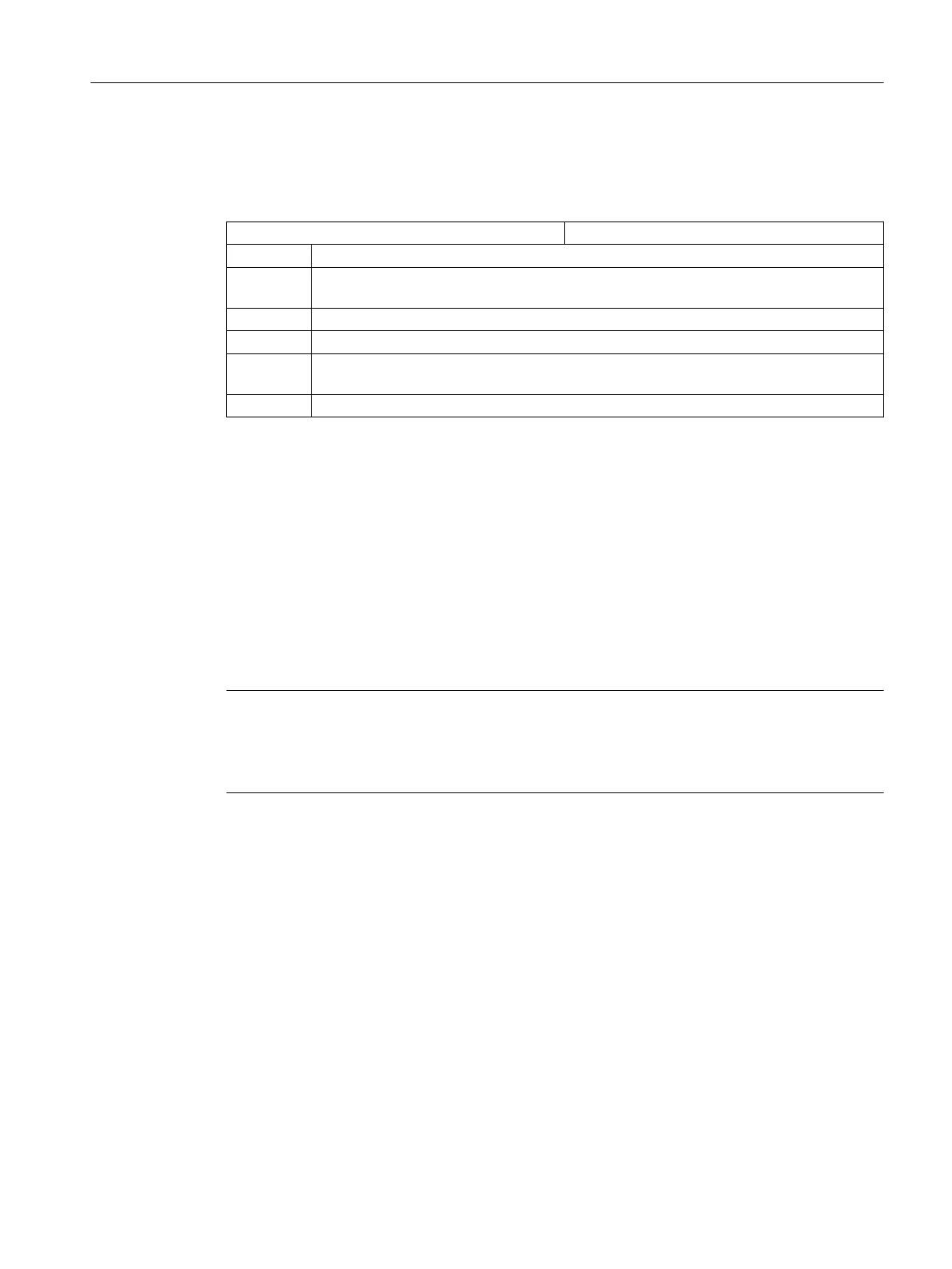

Cycle alarms 62186 and

62187 can be hidden or displayed using the following cycle machine

data:

MD55410 $MC_MILL_SWIVEL_ALARM_MASK Activate fault evaluation CYCLE800

Bit 0 Activates fault 61186

= 0 Hide fault 61186 "Active zero offset G%4 and base (base reference) contains rotations"

(default setting).

= 1 Display fault 61186

Bit 1 Activate fault 61187

= 0 Hide fault 61187 "Active base and base reference (G500) contain rotations" (default set‐

ting).

= 1 Display fault 61187

References

● Description of Functions Basic

Functions; Tool Offset (W1): Inclined surface machining with

3 + 2 axes

● Function Manual Special Functions: Multiple transformations (F2)

● Programming Manual, measuring cycles: CYCLE996

7.7.2 CYCLE800 checklist for the identification of the machine kinematics

Note

Identification of the machine kinematics (kinematic chain) according to DIN 66217 or ISO

841-2001

This checklist does not claim to be complete.

● Do the three linear axes of the machine that are active for the transformation form an

orthogonal coordinate system? Geometry axes XYZ

● How many swivel kinematics does the machine have?

Combinations of two (or one) rotary axis and the three linear axes are always formed.

● Which kinematics type is it?

Swivel head, swivel table or mixed kinematics of swivel head and swivel table.

● What are the names of the rotary axes of the kinematics?

Manual rotary axes are permitted and do not have to be declared in the NC.

● What is the 1st or 2nd rotary axis of a swivel data set?

Rule: Rotary axis 2

is based on rotary axis 1. With mixed kinematics, rotary axis 1 is always

the axis for the tool orientation.

● Is the traversing direction of the linear axes and the rotary axes correct? Right-hand rule

Rule: If the linear axis or the rotary axis moves the workpiece, the direction of motion of the

axis and also the sign of the rotary axis vector change.

Configuring cycles

7.7 Swiveling

SINUMERIK Operate

Commissioning Manual, 10/2015, 6FC5397-3DP40-5BA3 141

Loading...

Loading...