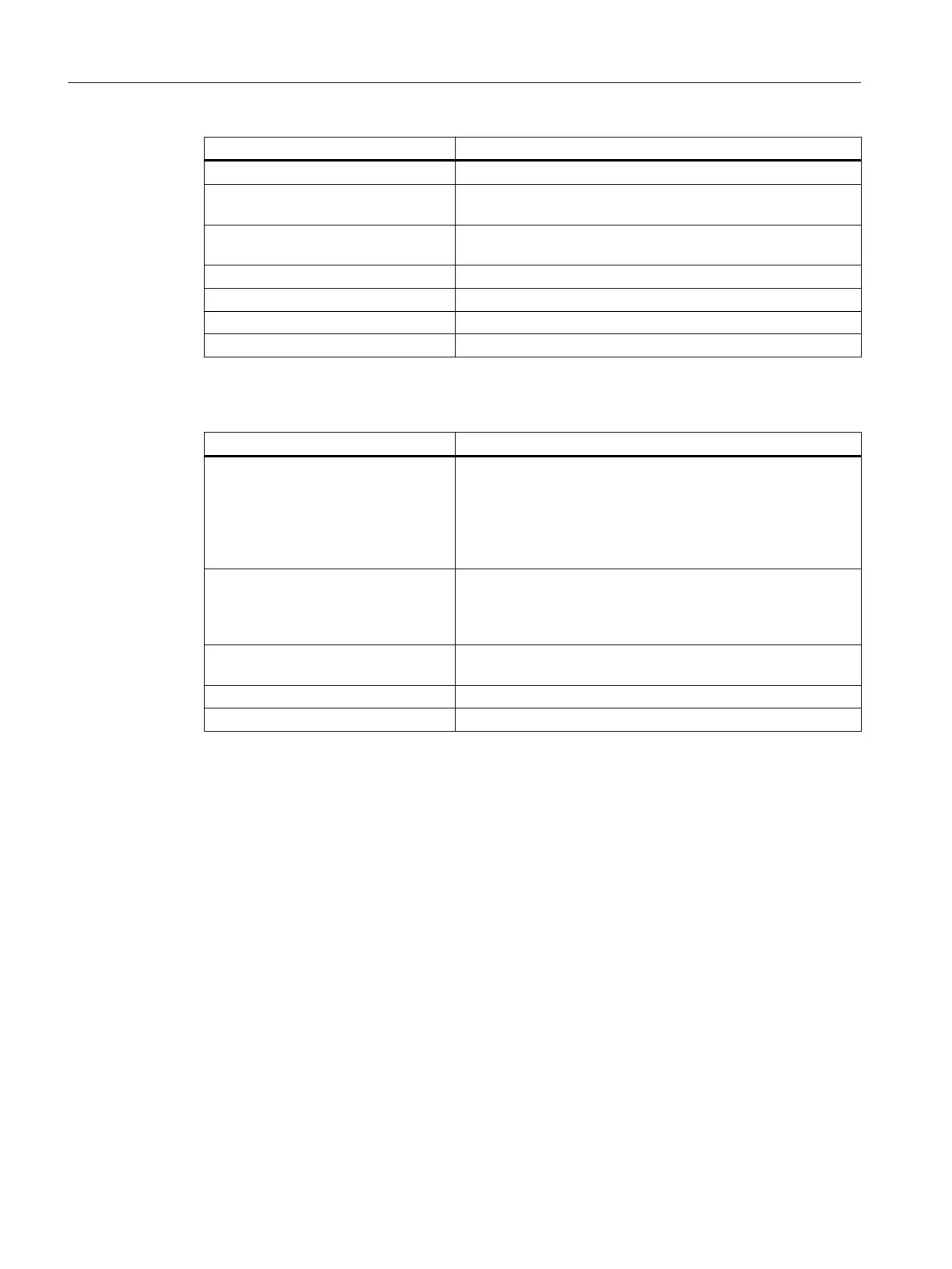

System variable Meaning

$A_TC_LTO Target location number of the old tool (to be removed).

$AC_TC_CMDT Trigger variable to output command of the NC (is set for one

IPO).

$AC_TC_ACKT Trigger variable for acknowledgment of the PLC (is set for one

IPO).

$AC_TC_CMDC Counter for the command output.

$AC_TC_ACKC Counter for the acknowledgments.

$AC_TC_MMYN Owner magazine number of the new tool (to be loaded).

$AC_TC_LMYN Owner location number of the new tool (to be loaded).

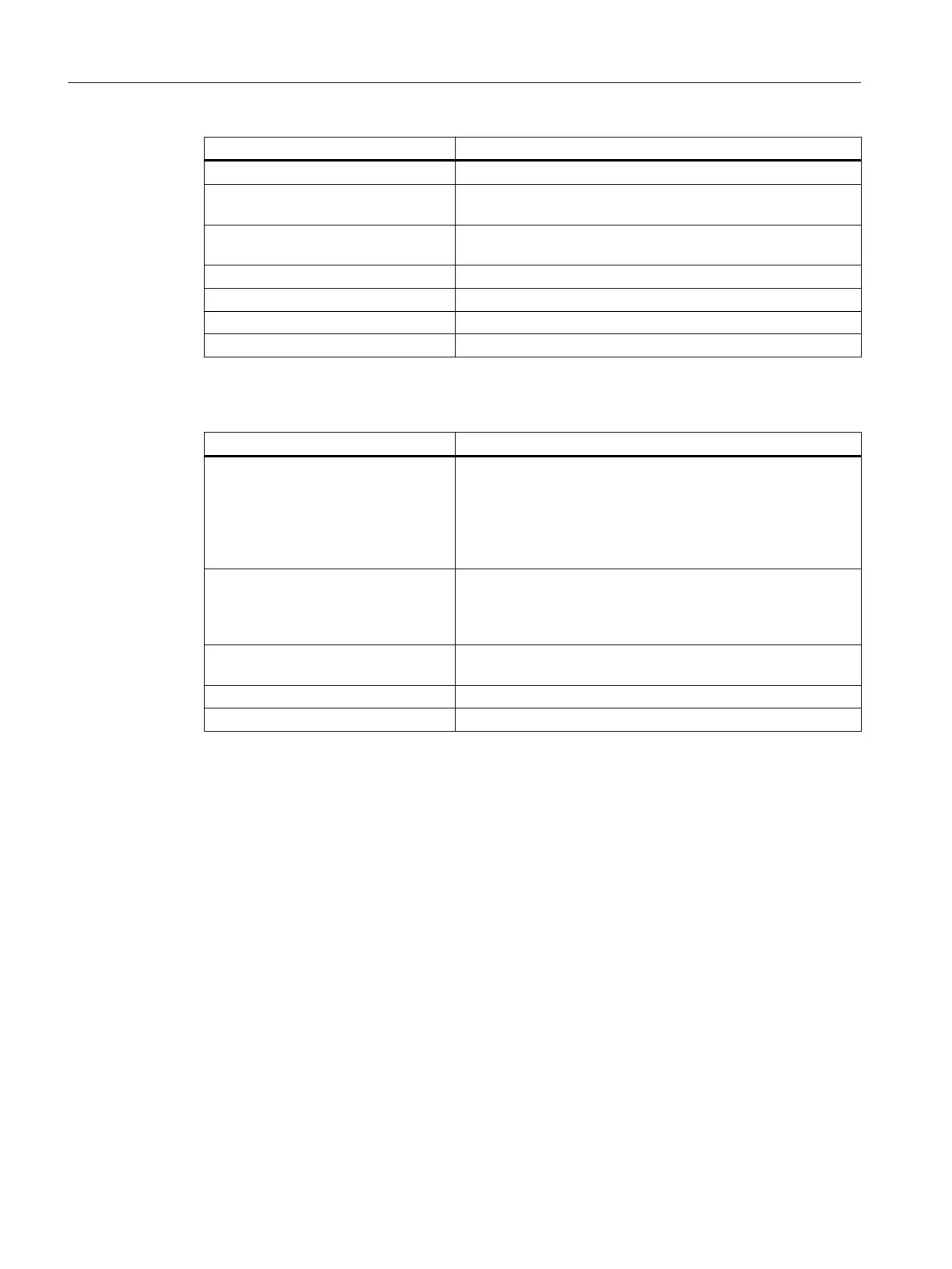

Supplementary system variables for a multitool

System variable Meaning

$AC_TC_TOOLIS Type of the tool be transported

0 = single tool

1 = multitool with location number as distance coding

2 = multitool with length separation as distance coding

3 = multitool with angular separation as distance coding

$AC_TC_MTDIST Distance of the new tool in the multitool from the reference

location. If the multitool has the length separation as distance

coding, the variable contains

the length in the unit mm or inch

as specified by the set dimension system.

$AC_TC_MTNLOC Number of locations of the new multitool present in the tool

change or tool transport.

$AC_TC_MTTN Number of the multitool in which the new tool is to be deployed.

$AC_TC_MTLTN Location number of the multitool with the new tool.

9.6 Working with two toolholders

It is possible to work on a single turning machine with two toolholders, both of which are

mounted on an X axis. The toolholders may be revolvers, multifix, or a combination of both.

As

both

tool

holders

are mounted on the same axis it is only possible to machine with one tool.

The workpiece is located between the two tool adapters.

All tools have the same reference point (on toolholder 1) irrespective of which toolholder they

are on. Consequently, the tool lengths of the second toolholder are always longer than the tool

lengths of the first toolholder. The main machining is performed in the negative X axis direction.

Tool management

9.6 Working with two toolholders

SINUMERIK Operate

304 Commissioning Manual, 10/2015, 6FC5397-3DP40-5BA3

Loading...

Loading...