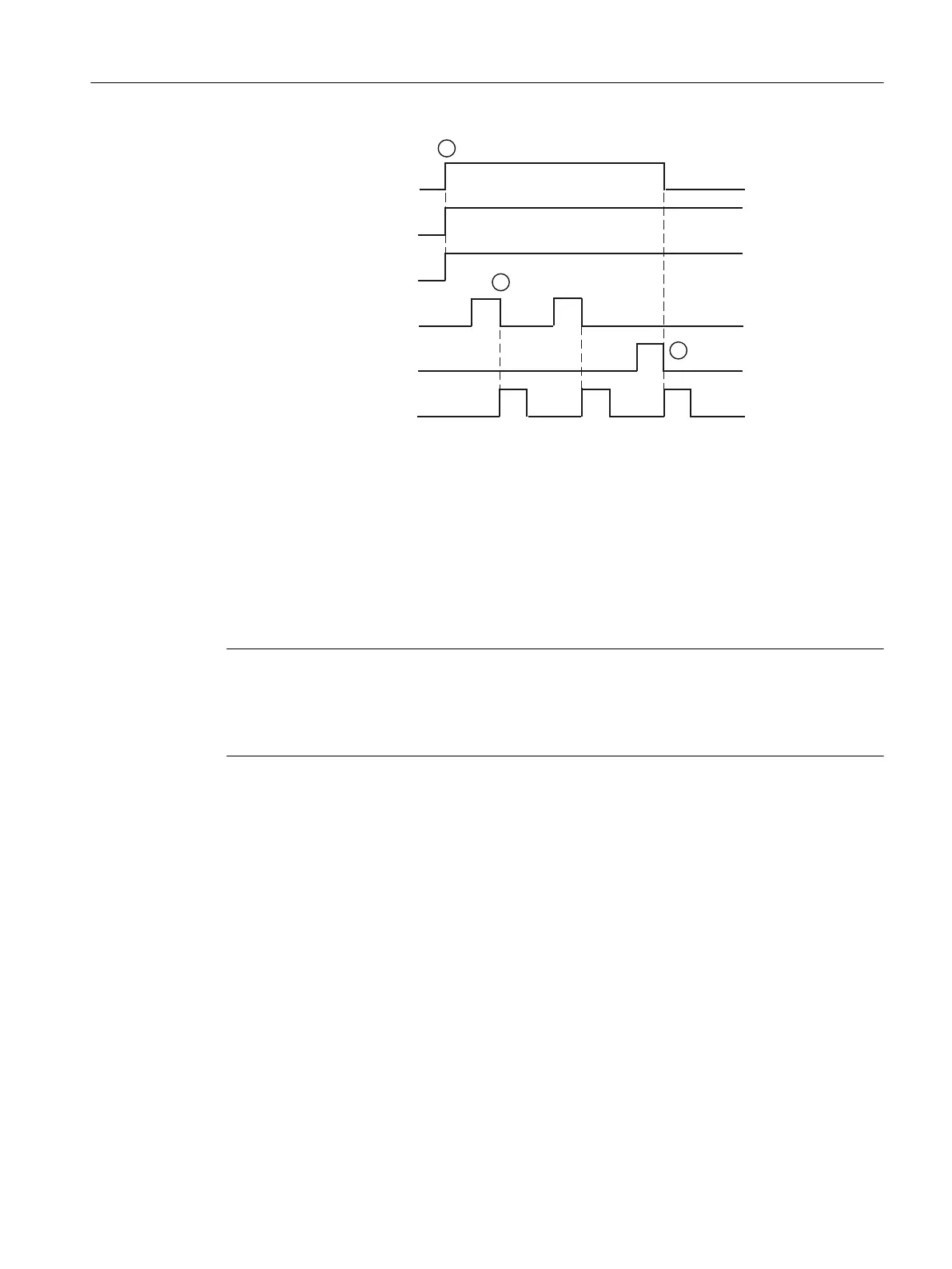

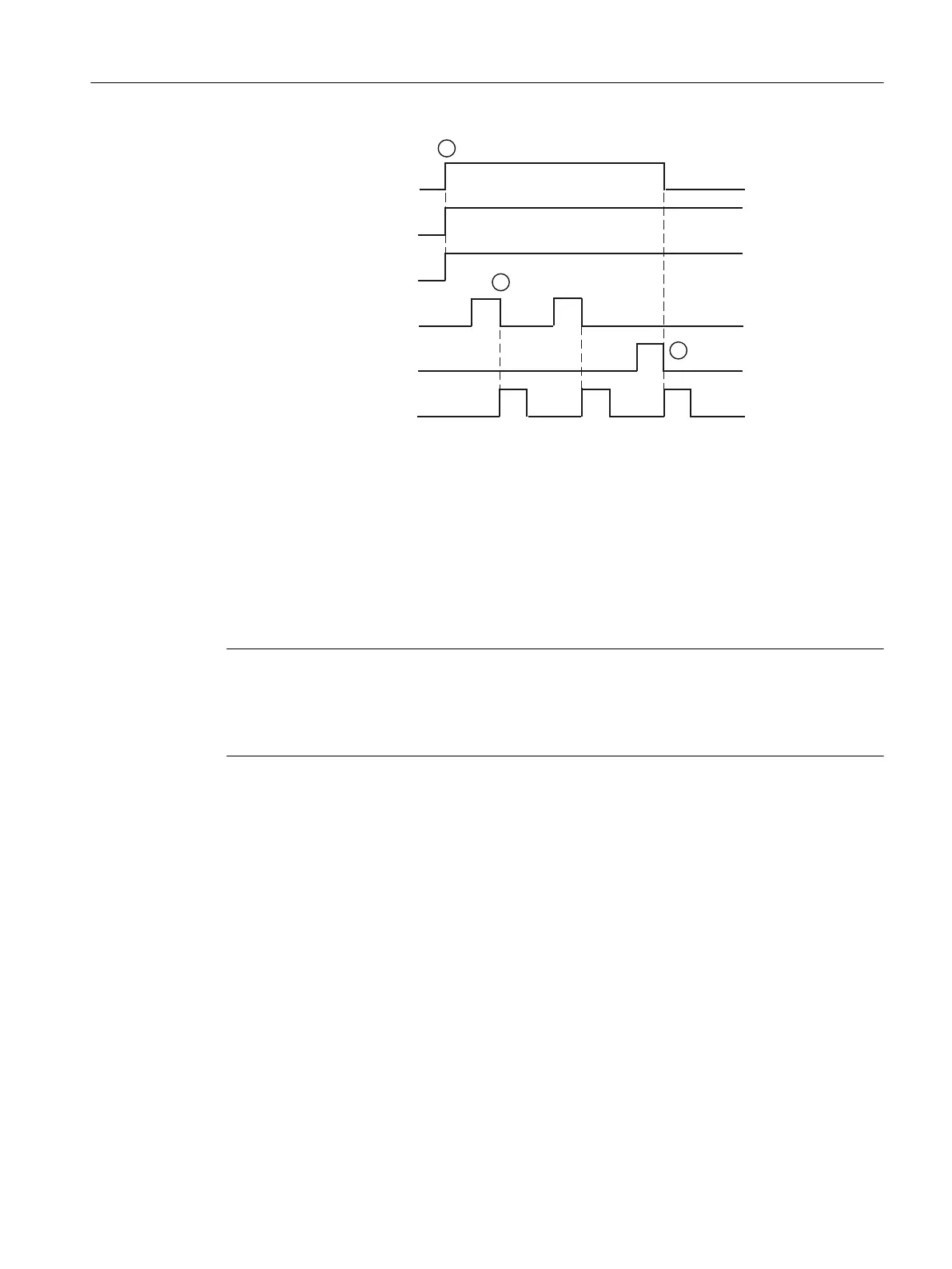

3UHSDUHDWRROFKDQJH

([HFXWHWRROFKDQJH

2UGHU

$FNQRZOHGJPHQW2.

(QGDFNQRZOHGJPHQW

,QWHUPHGLDWHDFNQRZOHGJPHQW

Signal description:

① The PLC user program receives a new job. The job "prepare tool change" and the job "execute

tool

change" are issued

simultaneously. Txx and M206 have been programmed in one NC block.

② Several intermediate steps are acknowledged. The state of the job remains unchanged. The

positions of the tools

are updated using the transfer steps of the acknowledgments from the tool

management.

③ The end acknowledgment OK is returned and the bit for the job is simultaneously reset.

The description of the job ("execute tool change" and "prepare tool change") is not reset. Byte

1 of DB43xx is not overwritten until the next job.

Note

MD20310: $MC_TOOL_MANAGEMENT_MASK

The response of the interface in DB43xx.DBB1 is affected by the setting in MD20310 bit 10.

This sequence described here corresponds to the presetting of the machine data.

9.4.4 Configuring step tables

Configuring step tables

You can find the transfer-step tables (TM_CTS, DB9900 and TM_VTS, DB9901) and the

acknowledgment-step table (TM_ACK, DB9902) in the Programming Tool under "Libraries"

→ "Special data blocks". The blocks are copied into a project with a double-click.

The structure of the data blocks is permanently fixed.

The blocks are not yet filled with the necessary data. The user must edit them in the

Programming Tool, via the menu "View" → "Data block". The constant tables (TM_CTS,

DB9900 and TM_ACK, DB9902) are configured by writing the initial data block values in the

Programming Tool.

The initial data block values are loaded into the control, along with the PLC user program.

Changed initial values are not activated until the PLC is restarted!

Tool management

9.4 PLC Program Blocks

CNC commissioning

Commissioning Manual, 10/2015, 6FC5397-3DP40-5BA3 289

Loading...

Loading...