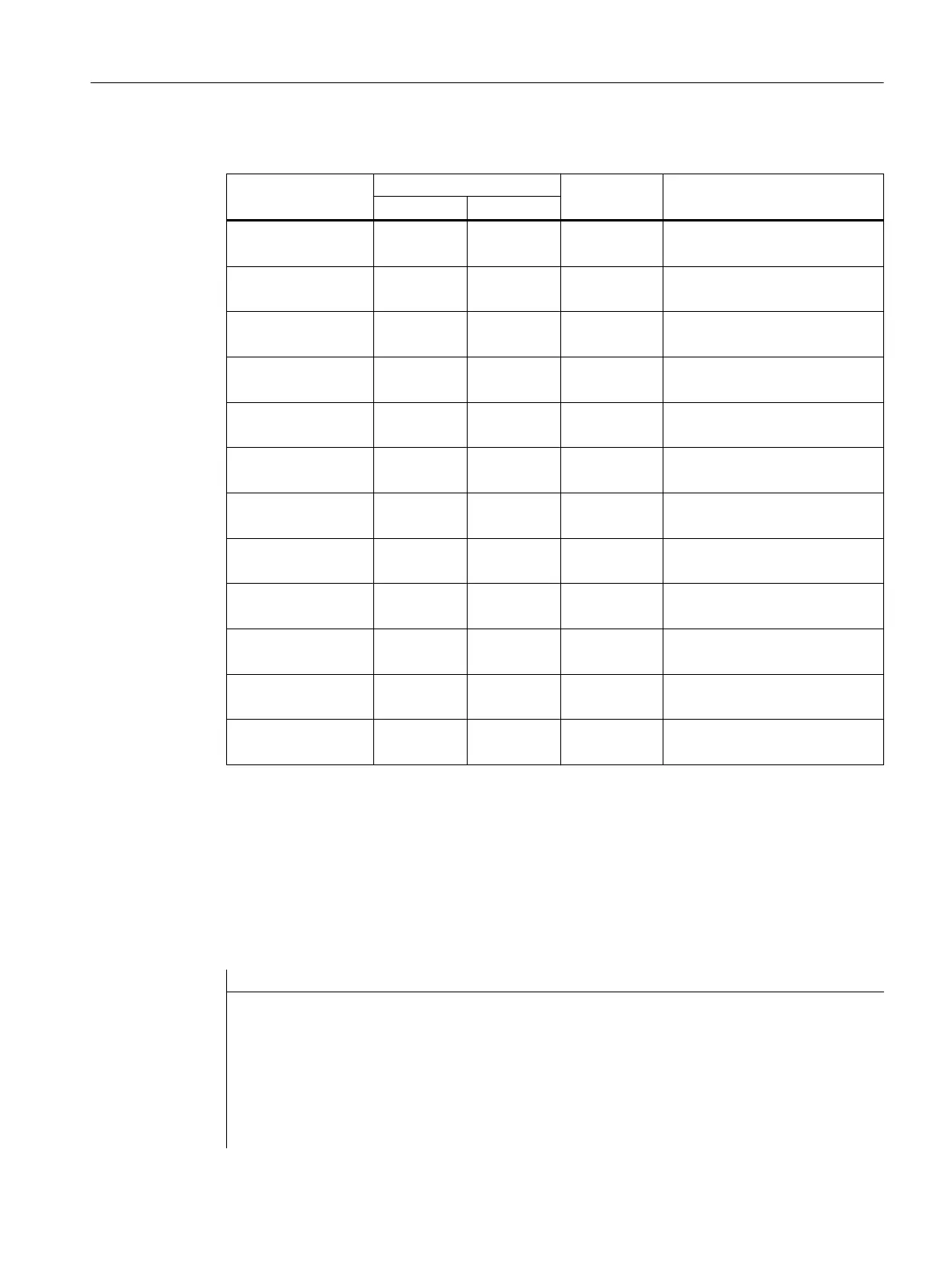

Acknowledgment step table

Acknowledgment

step

Transfer step Acknowledg‐

ment status

Comment

Old tool New tool

1

DB9902.DBW0

0 0 1 End acknowledgment,

Step ④ and ⑧

2

DB9902.DBW4

0 0 3 Cancel order

3

DB9902.DBW8

0 0 105 Intermediate acknowledgment

for subsequent order, Step ④

4

DB9902.DBW12

101 0 204 Variable magazine location to

changing point

5

DB9902.DBW16

1 2 105 Intermediate acknowledgment

Step ⑥

6

DB9902.DBW20

0 5 105 Intermediate acknowledgment

Step ③

7

DB9902.DBW24

3 4 105 Intermediate acknowledgment

Step ⑦

8

DB9902.DBW28

0 2 105 Intermediate acknowledgment

Step ⑨

9

DB9902.DBW32

0 4 105 Intermediate acknowledgment

Step ⑩

10

DB9902.DBW36

1 0 105 Intermediate acknowledgment

Step ⑬

11

DB9902.DBW40

3 0 105 Intermediate acknowledgment

Step ⑭

12

DB9902.DBW44

-- -- --

Note: The step numbers ① ... ⑭ refer to the flow chart in Chapter Flow chart: Tool change

(Page 321)

9.8.4

Example: Tool change cycle for milling machine

Sample program

PROC L6 SAVE DISPLOF

;----------------------------------------------------------------

; Example of a tool change cycle for machine manufacturers

;----------------------------------------------------------------

DEF INT _WZ_IN_SP,_WZ_VOR

DEF REAL _SPP= ...

;

; spindle position

Tool management

9.8 Application example for milling machine

CNC commissioning

Commissioning Manual, 10/2015, 6FC5397-3DP40-5BA3 331

Loading...

Loading...