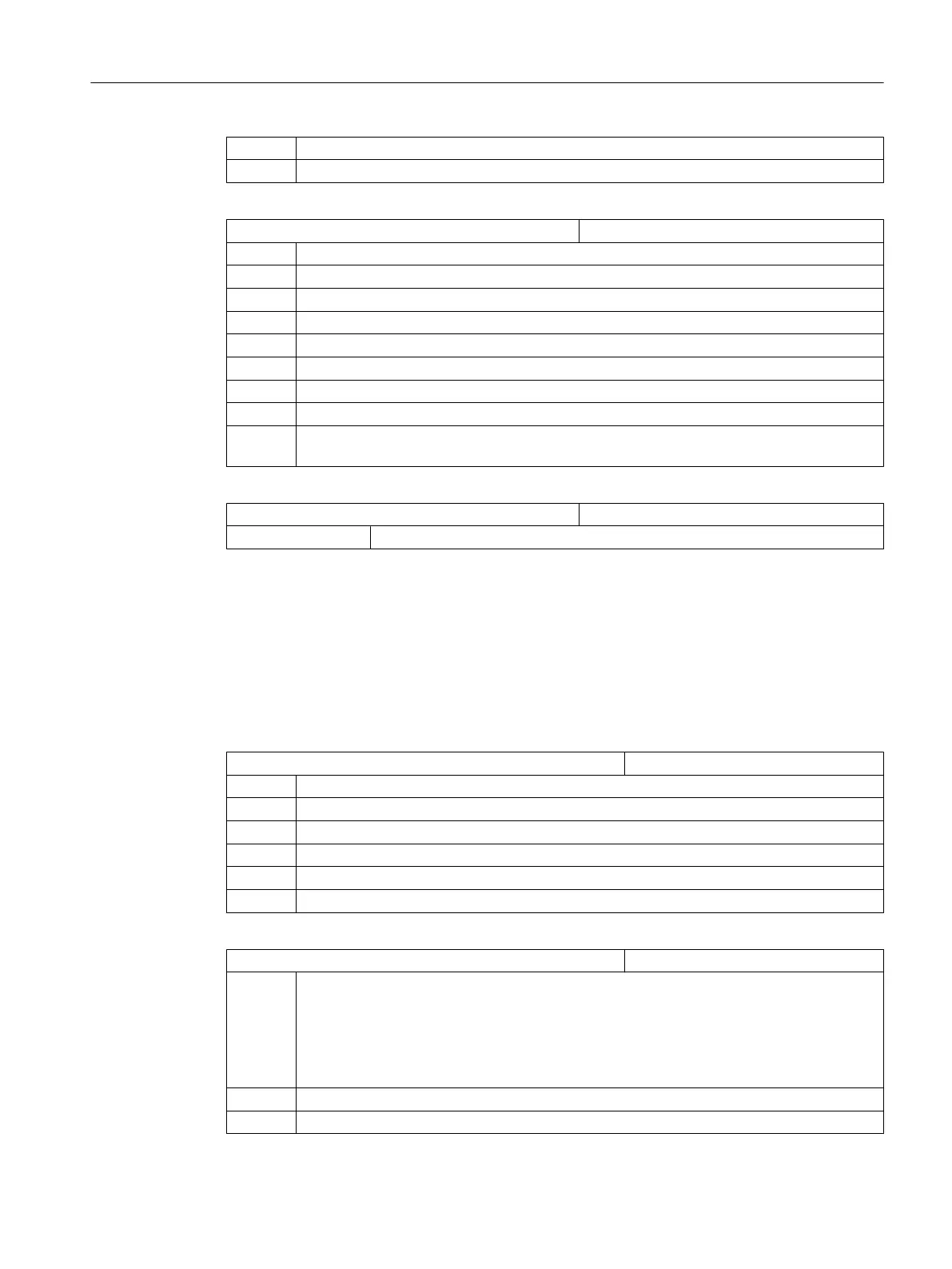

= 18 G18 plane (permanently set)

= 19 G19 plane

MD52212 $MCS_FUNCTION_MASK_TECH Cross-technology function screen

Bit 0 Enable swivel with tool holder

= 0 Swivel plane, swivel tool not enabled

= 1 Swivel plane, swivel tool enabled

Bit 1 Optimized travel along software limit switches

= 0 No optimized travel along software limit switches

= 1 Optimized travel along software limit switches

Bit 5 Call block search function SERUPRO.

= 0 CYCLE207 is not called in the block search cycle PROG_EVENT.SPF.

= 1 The cycle for SERUPRO (CYCLE207) is called in the block search cycle

PROG_EVENT.SPF

MD52240 $MCS_NAME_TOOL_CHANGE_PROG Tool change program for G code steps

= Program name The associated program is called for tool change.

7.2 Technology cycles for drilling

Drilling technology

You

can

set

drilling

technology using the following channel-specific configuration machine data

and channel-specific cycle setting data.

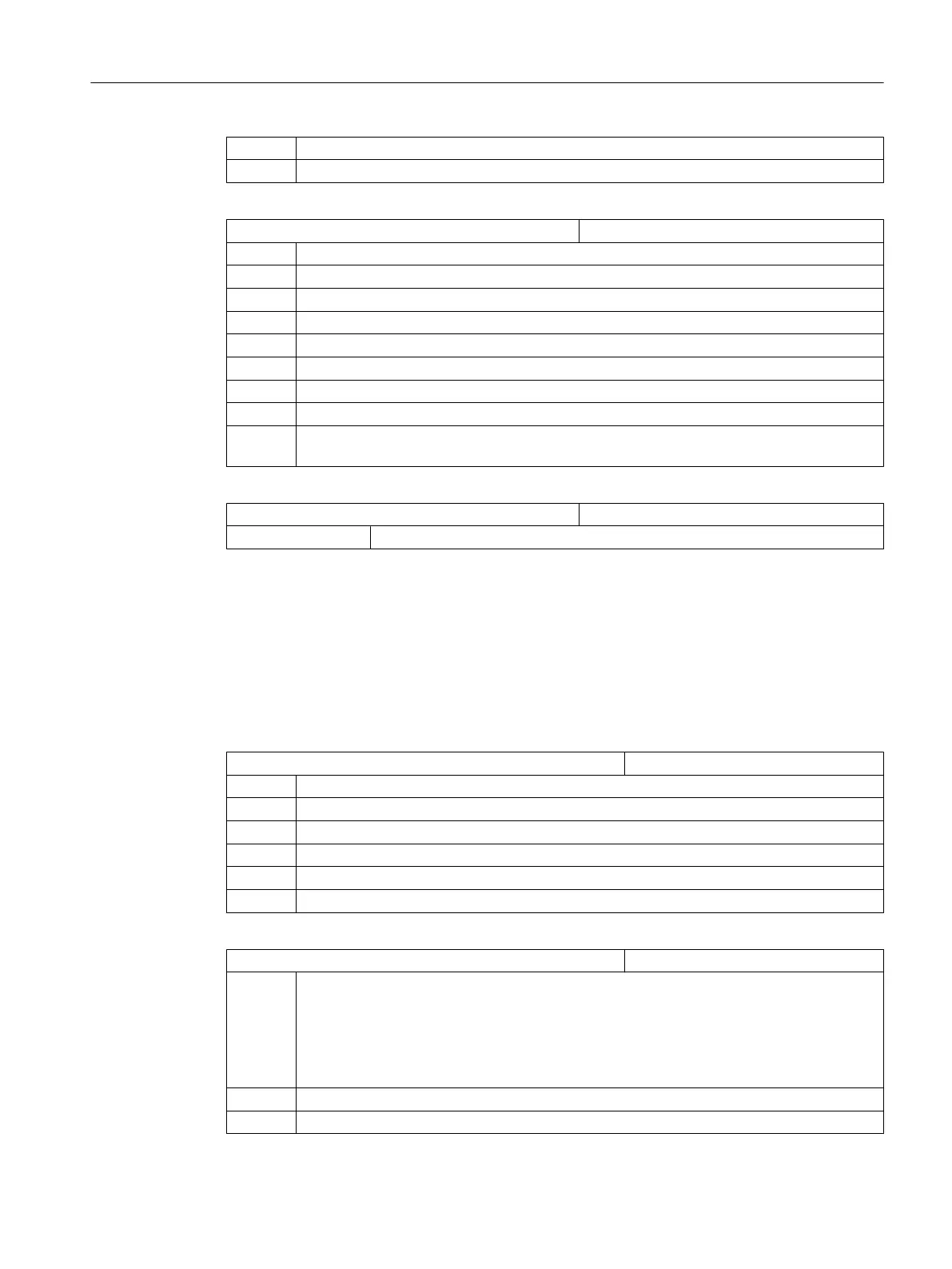

MD52216 $MCS_FUNCTION_MASK_DRILL Drilling function screen form

Bit 0 Tapping cycle CYCLE84, technology input fields

= 0 Hide input fields

= 1 Display input fields

Bit 1 Tapping cycle CYCLE840, technology input fields

= 0 Hide input fields

= 1 Display input fields

SD55216 $SCS_FUNCTION_MASK_DRILL_SET Drilling function screen form

Bit 1 Boring CYCLE86: Take into account the rotation of the tool plane when positioning the

spindle

Note:

Spindle

direction of rotation

M3/ M4 and direction of rotation of the rotary axes must be set

according to DIN. For SPOS=0, the tool cutting edge points in the + direction of the 1st axis

of the plane (for G17, to X+).

= 0 Do not take into account the rotation of the tool plane when positioning the spindle (SPOS).

= 1 Take into account the rotation of the tool plane when positioning the spindle (SPOS).

Configuring cycles

7.2 Technology cycles for drilling

SINUMERIK Operate

Commissioning Manual, 10/2015, 6FC5397-3DP40-5BA3 79

Loading...

Loading...