Design Guidelines

Puck Limits

MagneMover LITE User Manual 125

Rockwell Automation Publication MMI-UM002F-EN-P - October 2022

High Inertia Payloads

The following guidelines are provided when using loads with a high inertia that are mounted

on the puck. High inertia loads typically have a large off-center mass, have a high center of

gravity, or exceed the payload envelopes that are shown in Figure 3-27, Figure 3-30,

Figure 3-33, and Figure 3-36. Contact your Motion Solutions Consultant or Technical Support

(see Rockwell Automation Support on page 486) for design guidelines for applications where

the payload does not fit into the envelope shown in Pucks on page 105.

Vehicle motion can become erratic due to the inertia of the vehicle and payload as it enters and

exits curves. The larger the inertia, the more erratic motion is through both curve motors and

the curve section of switches. This erratic behavior becomes worse as the mass or velocity is

increased. Use a high payload switch (shown in Figure 4-27 and Figure 4-30) to help avoid

some of the erratic motion when moving through a switch.

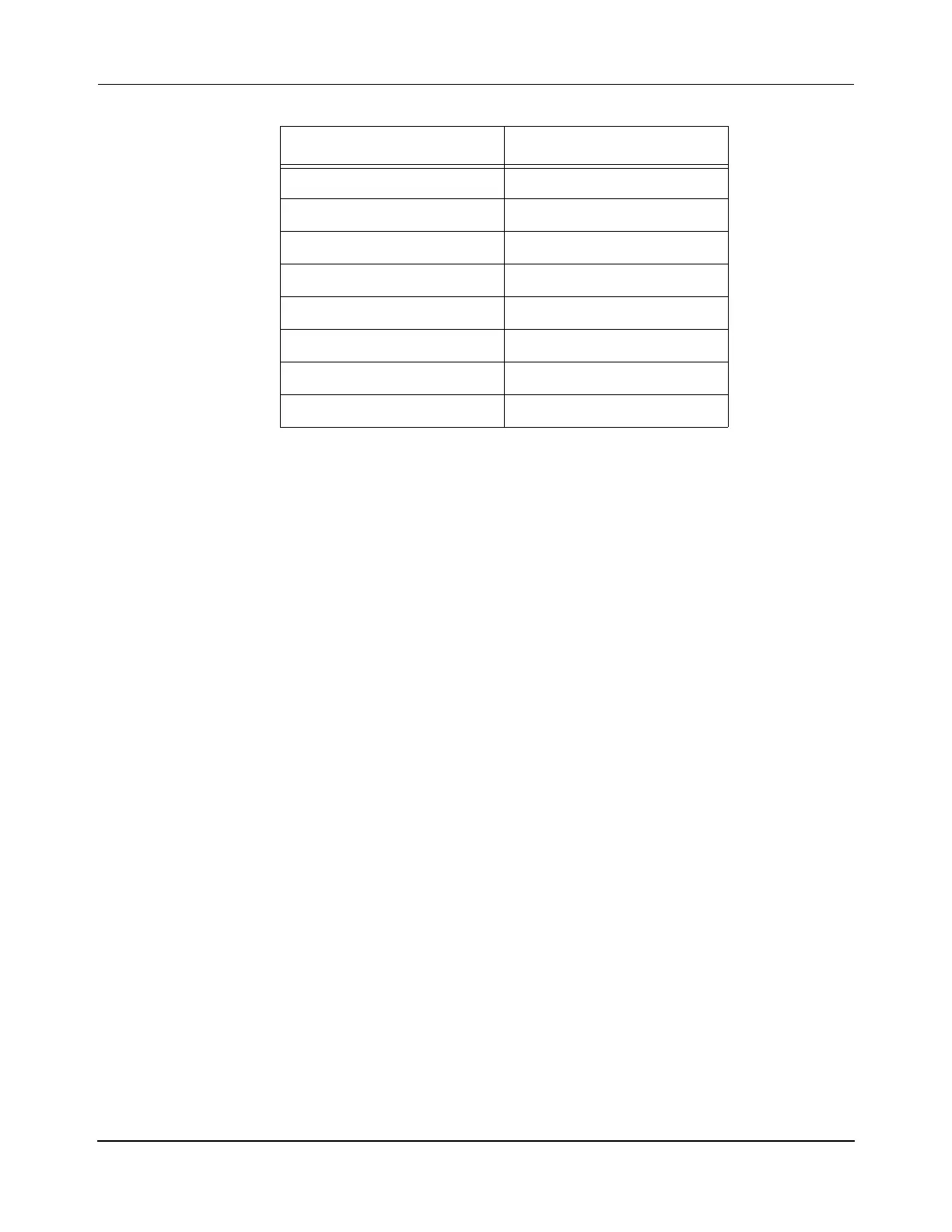

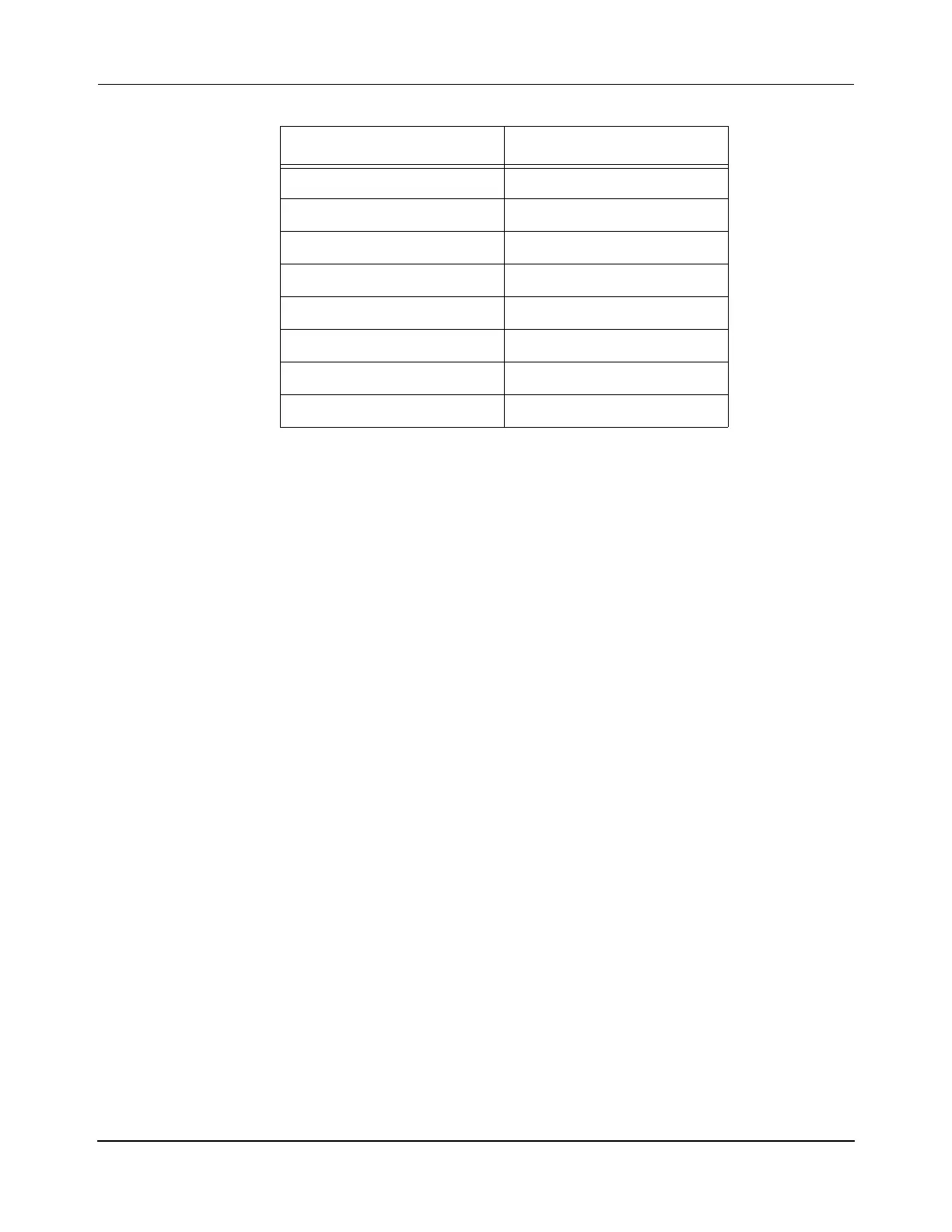

80 321

90 293

100 270

110 250

120 233

130 218

140 205

150 193

Table 3-4: Single Glide Puck Carrier Overhang Limits (Continued)

Overhang Length (mm) Maximum Load (g)

Loading...

Loading...