Operation

Theory of Operation

MagneMover LITE User Manual 321

Rockwell Automation Publication MMI-UM002F-EN-P - October 2022

Anti-Collision

The MagneMover LITE transport system allows only one vehicle per motor block. This block

allocation is the basic rule on which the anti-collision feature of the MM LITE transport sys-

tem controls is founded. Since two vehicles are not allowed to be in the same motor block,

they cannot collide. This block allocation affects how many vehicles can fit on a motor or

path.

Also, the magnet arrays on the vehicles have a slight repulsive force that causes them to pas-

sively separate from each other a short distance when they are manually pushed together and

not being servoed (actively controlled). The distance they passively separate varies based on

vehicle (puck) and track conditions (including friction).

The vehicles can be commanded to a tighter spacing but this spacing requires constantly driv-

ing the motor to force them together. They can be commanded to a pitch where they are prac-

tically in contact with each other but if this constant, close position condition is held too long

the motors reach a thermal limit and shut down. This tight spacing can be done on occasion

but it cannot be a standard part of a process.

Safe Stopping Distance

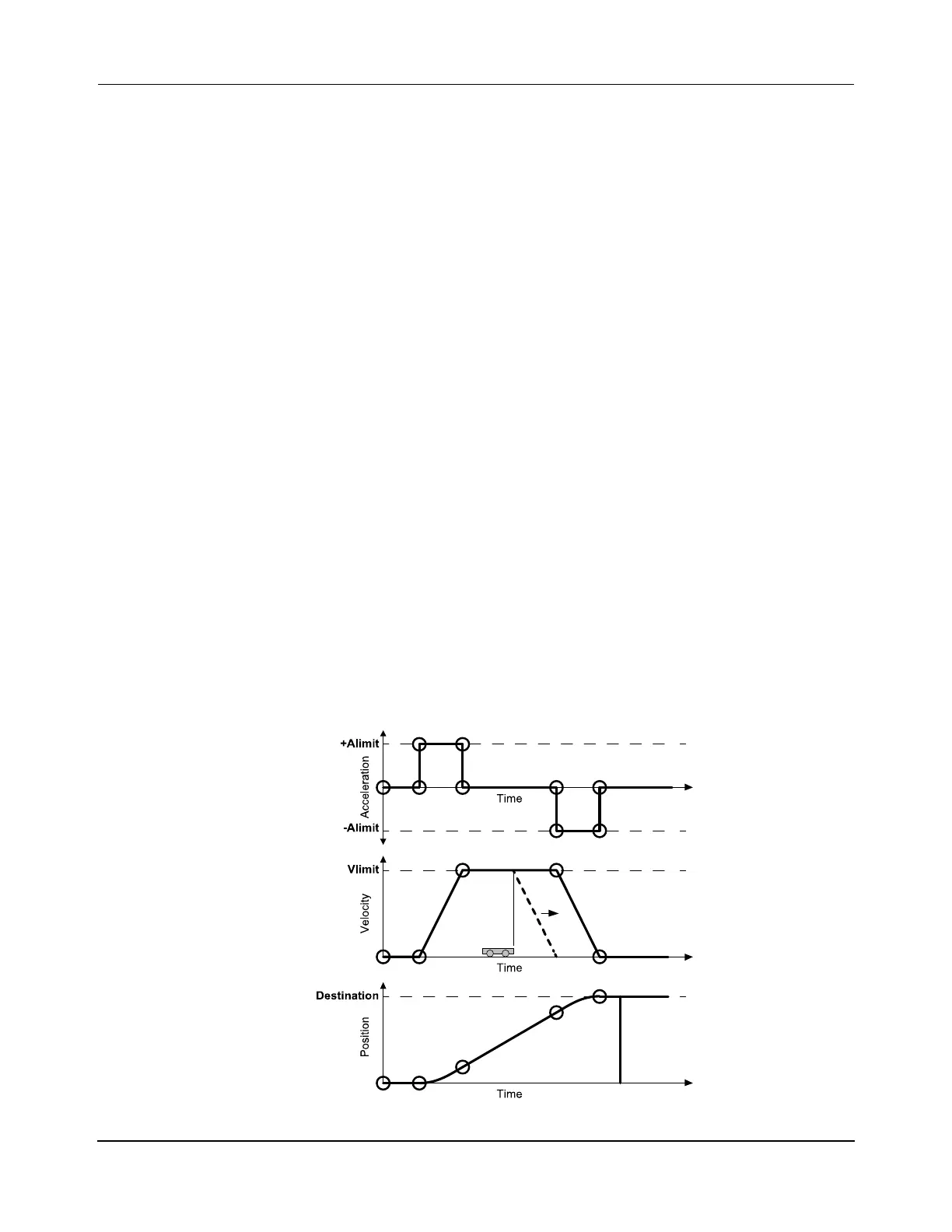

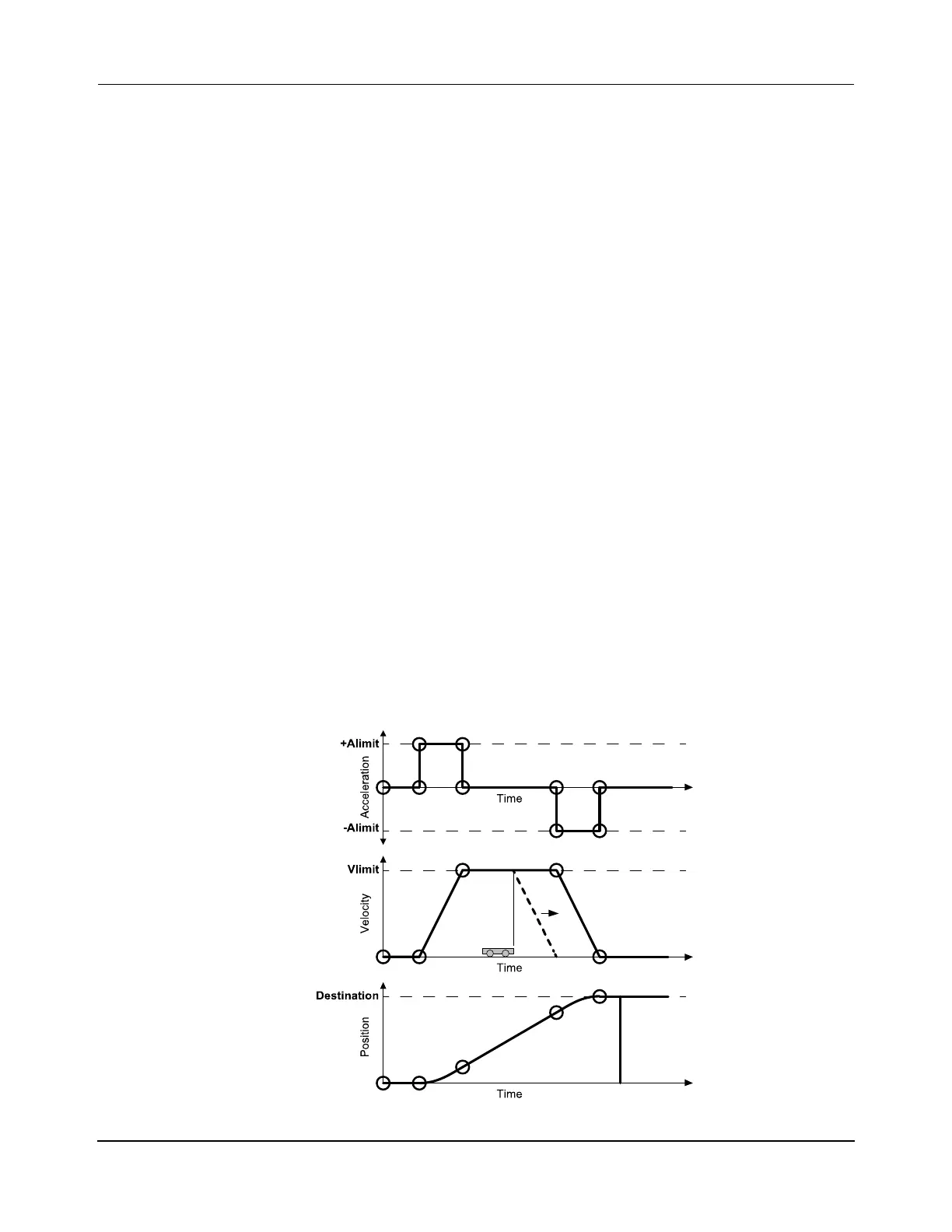

Standard vehicle control and operation make sure that vehicles (pucks) always have a safe

stopping distance (brick-wall headway). Figure 6-5 shows acceleration, velocity, and position

versus time for the standard vehicle motion profile. Permission for vehicle motion is granted

as required on a block-by-block basis. This permission keeps vehicles on their move profile

(solid heavy line) and provides a safe stopping distance (dashed heavy line) based on the cur-

rent velocity and commanded acceleration of the vehicle. This stopping distance can be found

by dividing the square of the current velocity of a vehicle by twice its acceleration (V

2

/2a).

Figure 6-5: Vehicle Movement Profile

Loading...

Loading...