Maintenance

Preventive Maintenance

346 MagneMotion

Rockwell Automation Publication MMI-UM002F-EN-P - October 2022

Preventive Maintenance

The motors, node controllers, and power supplies in the MagneMover LITE transport system

are self-contained components that are designed for use in a clean, inert environment, and

require no maintenance other than that described here. See Troubleshooting on page 371 if

any problems are detected.

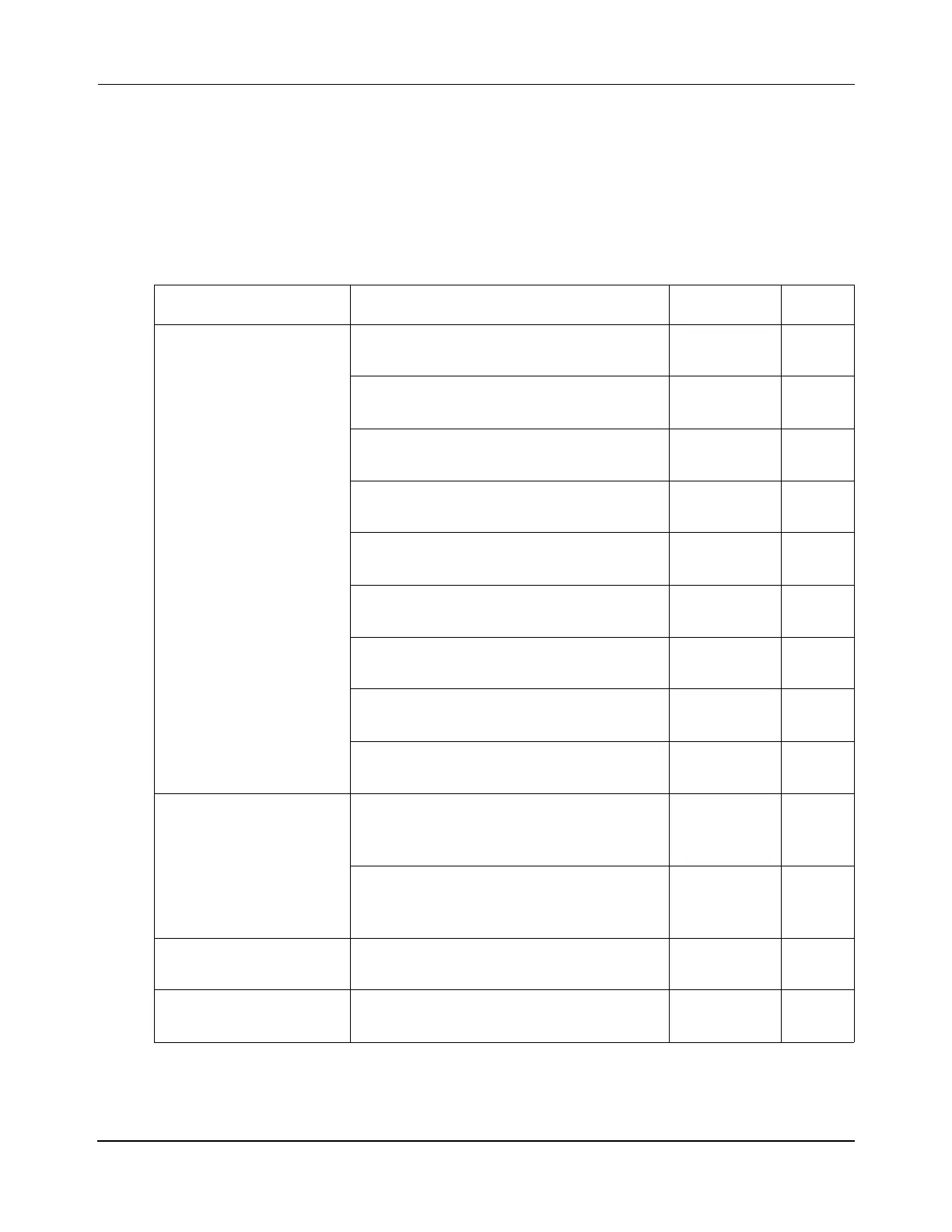

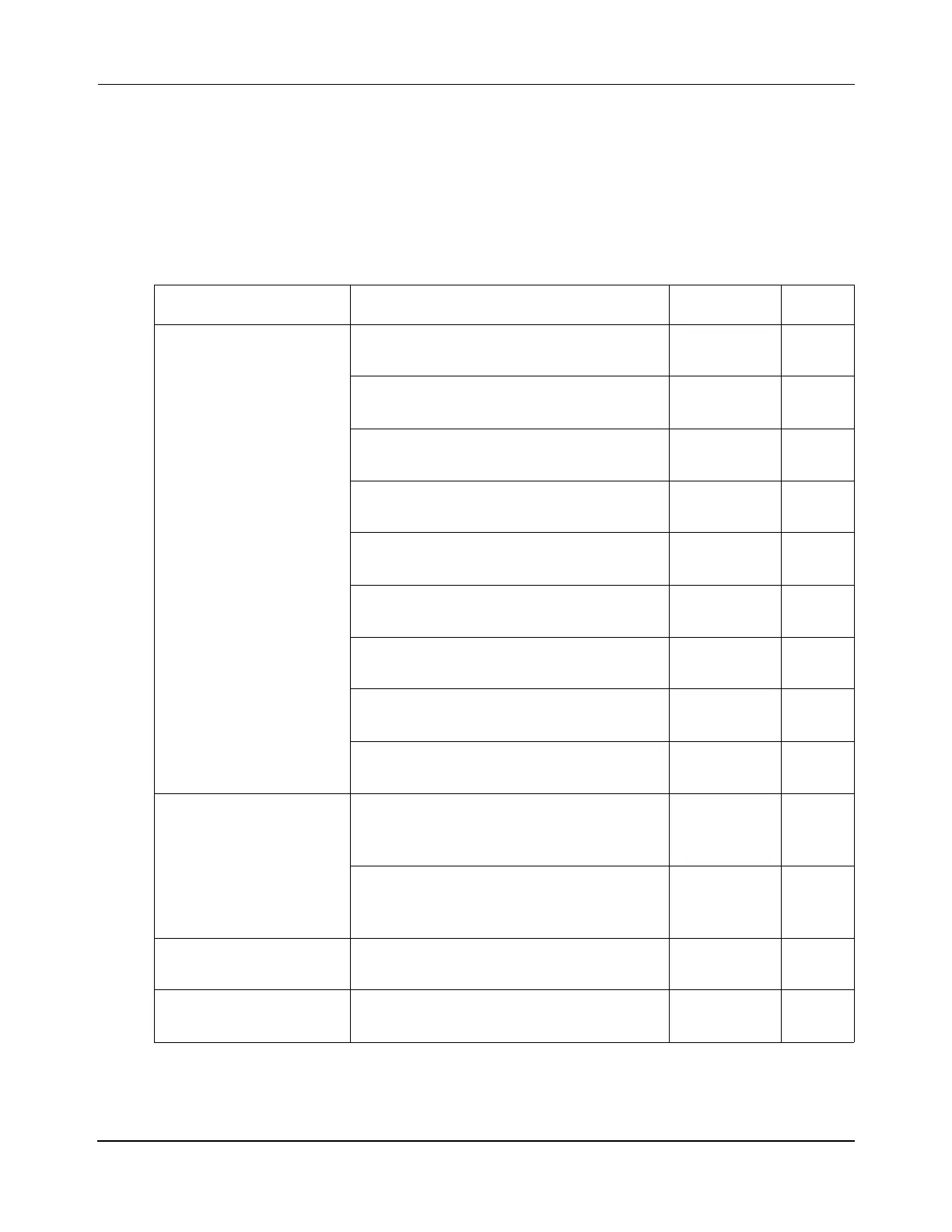

Table 7-1: MagneMover LITE Preventive Maintenance Schedule

Component Maintenance Action Frequency

*

Page #

MagneMover LITE

Transport System

General Cleaning 3 months or

as required

348

Spray Cleaning 3 months or

as required

348

Glide Puck Cleaning 3 months or

as required

350

Puck Wear Surface Maintenance 3 months or

as required

352

Wheeled Puck Cleaning 3 months or

as required

354

Wheeled Puck Wear Surface Maintenance 3 months or

as required

356

Cable Connection Inspection 3 months or

as required

359

Hardware Inspection 3 months or

as required

359

Cleaning Magnet Arrays 3 months or

as required

360

Air-cooled Motor Verify that the air supply is at or below

1.0 psig [6.9 kPa] pressure and the flow is

at or below 4.0 SCFM [113 L/min].

3 months or

as required

–

Verify that the air quality is per ANSI

7.0.01-1996, Quality Standard for Instru-

ment Air.

3 months or

as required

–

Node Controllers Transfer Log Files 3 months or

as required

359

Power Supplies Clean or Replace the MM LITE Power Sup-

ply Air Filter

12 months or

as required

361

Loading...

Loading...