Installation

Option Installation

290 MagneMotion

Rockwell Automation Publication MMI-UM002F-EN-P - October 2022

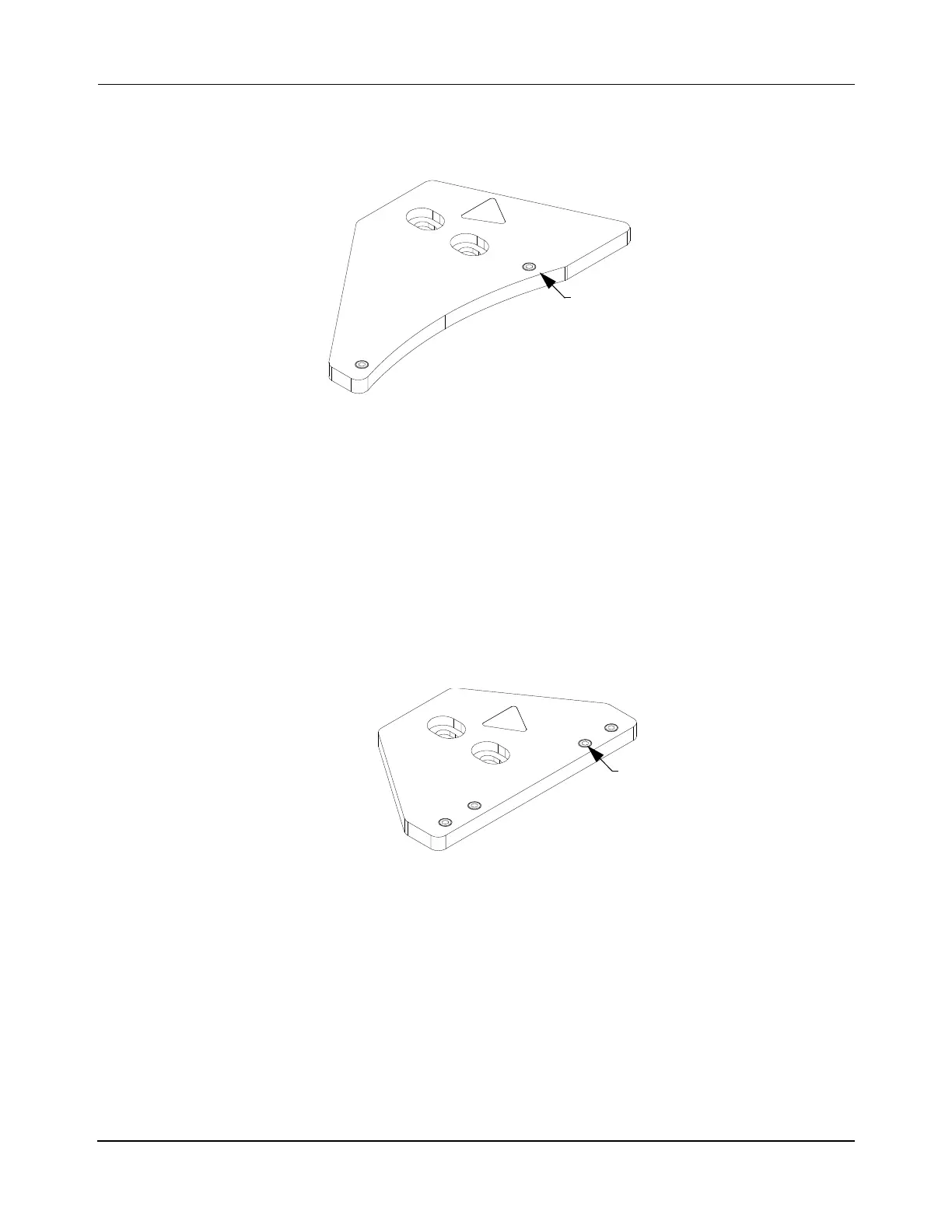

Curved Rail, No Joint Locations

See Figure 5-38 when aligning and securing all 180° curved rails at mid-point locations.

Figure 5-38: Tightening Sequence, 180° Curve No Joint Precision Rail Spine Plate

1. Once the rail is aligned, tighten each screw to 1.8 N•m [16 in•lb] following the

sequence shown in Figure 5-38.

2. Repeat Step 1 for all 180° curved rails at the mid-point.

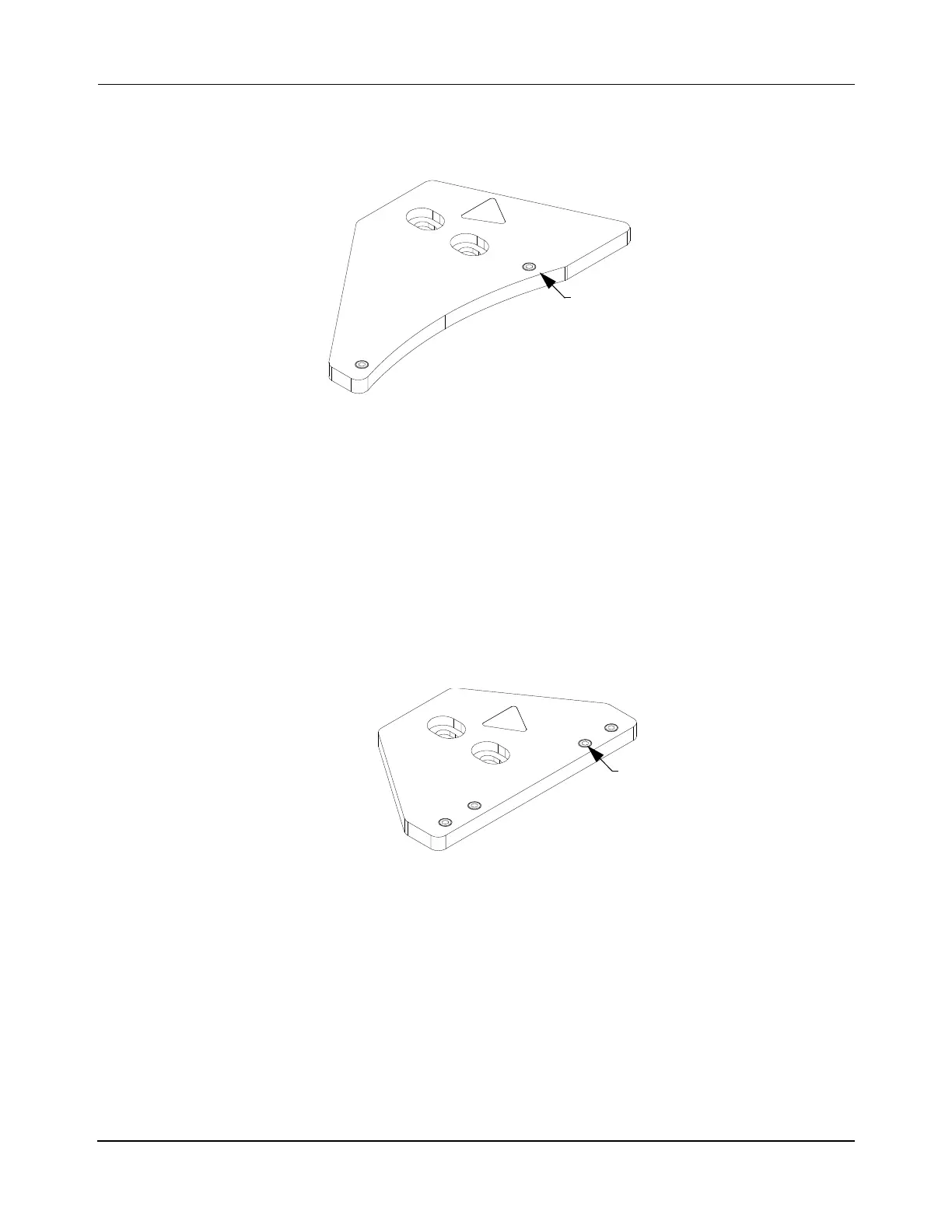

Straight, No Joint Locations

See Figure 5-39 when aligning and securing all straight rails at mid-point locations. For

greater stability, it is recommended that spine plates are located every 500 mm along straight

rail segments that are greater than 500 mm long.

Figure 5-39: Tightening Sequence, Straight Rail No-Joint Precision Rail Spine Plate

1. Once the rail is aligned, tighten each screw to 1.8 N•m [16 in•lb] following the

sequence shown in Figure 5-39.

2. Repeat Step 1 for all points on the rail.

3. Repeat Step 1 and Step 2 for all straight rail segments that are greater than 500 mm in

long.

Loading...

Loading...