Installation

Transport System Installation

260 MagneMotion

Rockwell Automation Publication MMI-UM002F-EN-P - October 2022

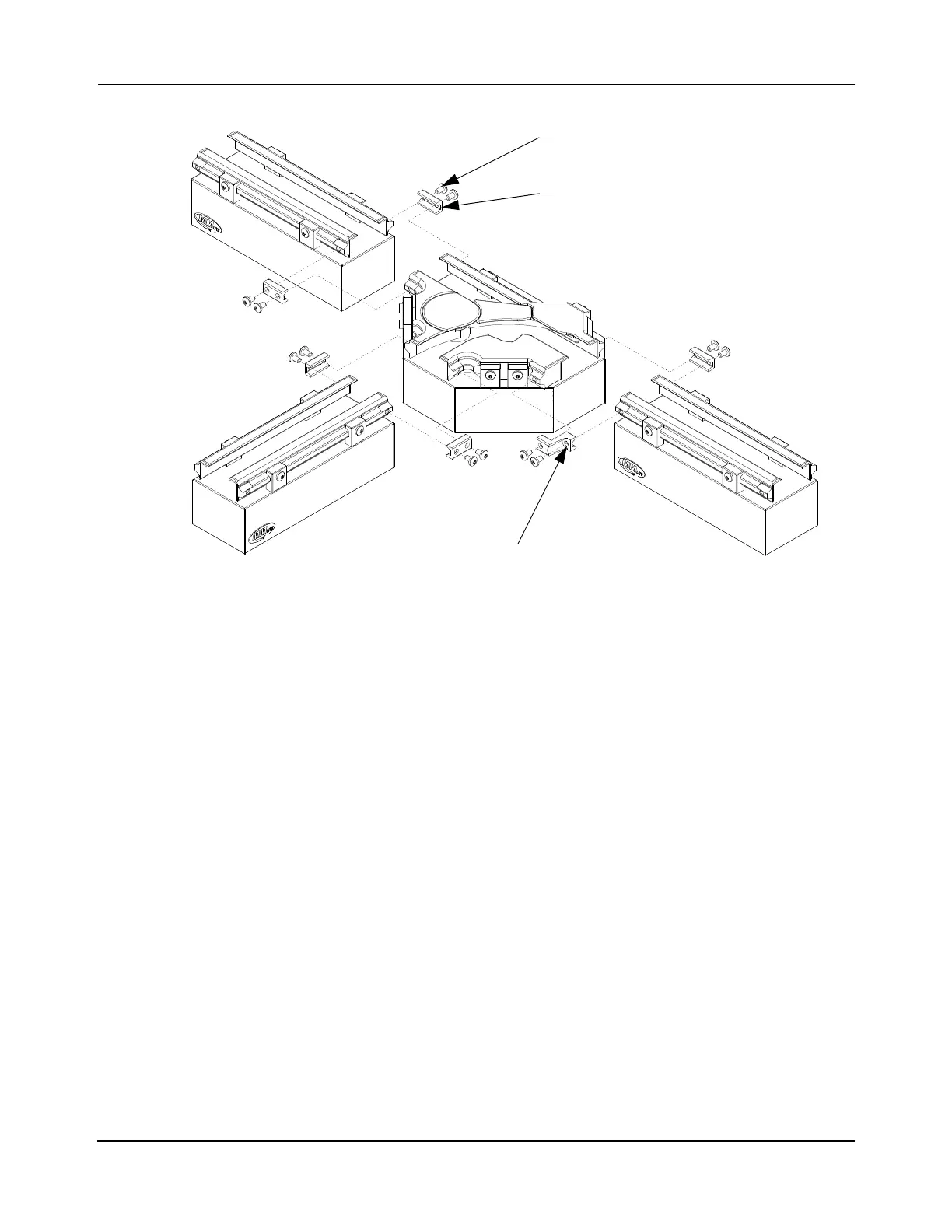

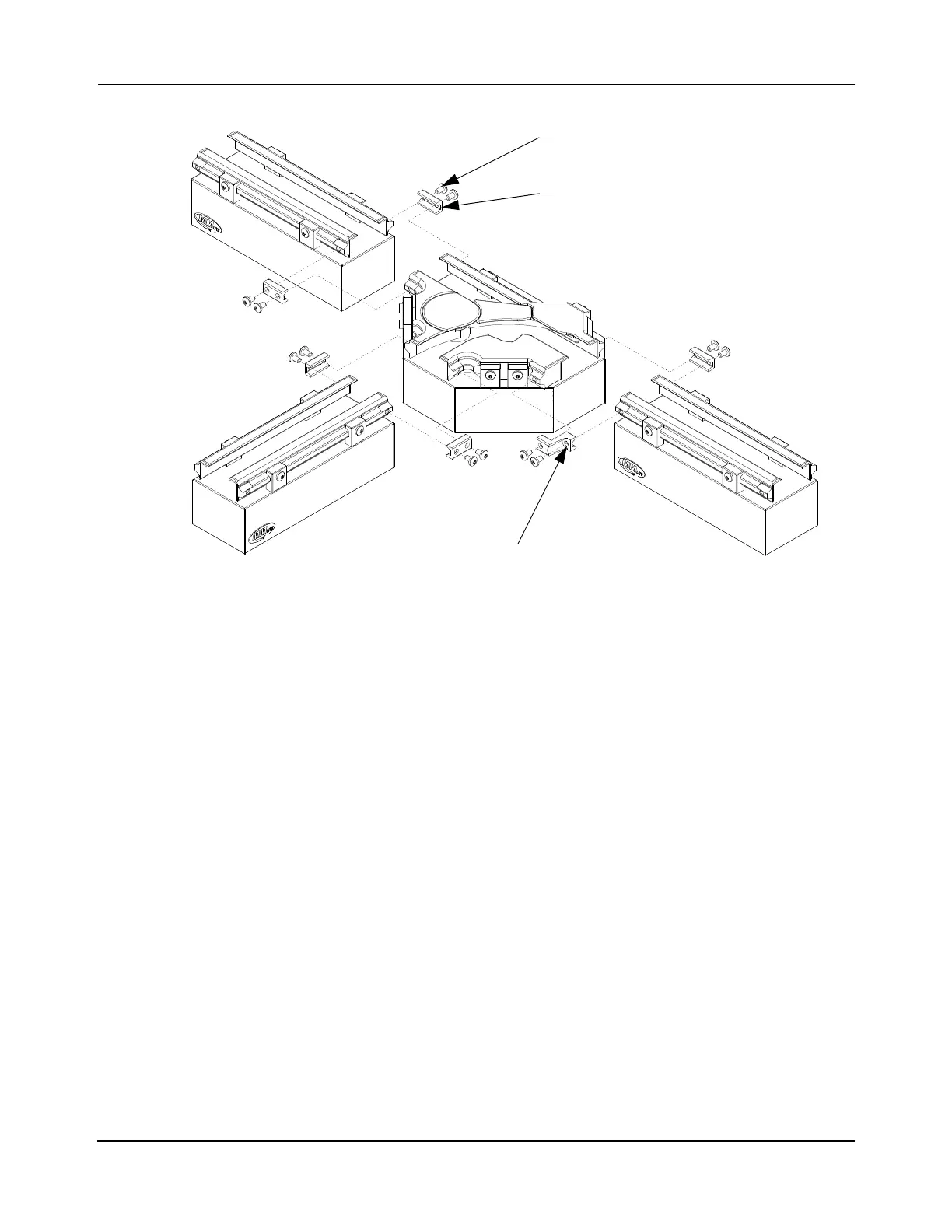

Figure 5-14: Install High Payload Switch

1. Loosen the M6 bolt used to secure the switch to the motor mount for all switches being

adjusted if necessary.

2. For aluminum rails, install the appropriate V-braces at all guide rail joints using M6 x

12 mm screws and tighten finger-tight to pull the rails together.

NOTE: The guide rail joints on the aluminum rails contain locking inserts, which

limit the depth of insertion when finger tightening.

For stainless steel rails, install the appropriate V-braces at all guide rail joints using

M6 x 12 mm screws with Loctite 243 and tighten finger-tight to pull the rails together.

3. Using fingers, align the rails at the switch joints as shown in Figure 5-13 and

Figure 5-14. Tighten the two M6 x 12 mm screws on each V-brace at that switch joint

to 3.4 N•m [30 in•lb] with a T30 Torx bit.

4. Tighten the M6 bolt to 5.5 N•m [49 in•lb] with a 10 mm Hex socket to secure the

switch to the motor mount.

For stainless steel rails the Loctite must cure for 2 hours at 22° C [72° F] before using

the transport system.

5. Repeat Step 3 at all switch joints.

6. Repeat Step 4 at all switches.

Standard V-brace

(5X 200-2002-XX)

LF Switch V-brace

(200-2450-XX)

M6 x 12 mm Screw

(2X per V-brace)

Loading...

Loading...