Maintenance

Preventive Maintenance

MagneMover LITE User Manual 369

Rockwell Automation Publication MMI-UM002F-EN-P - October 2022

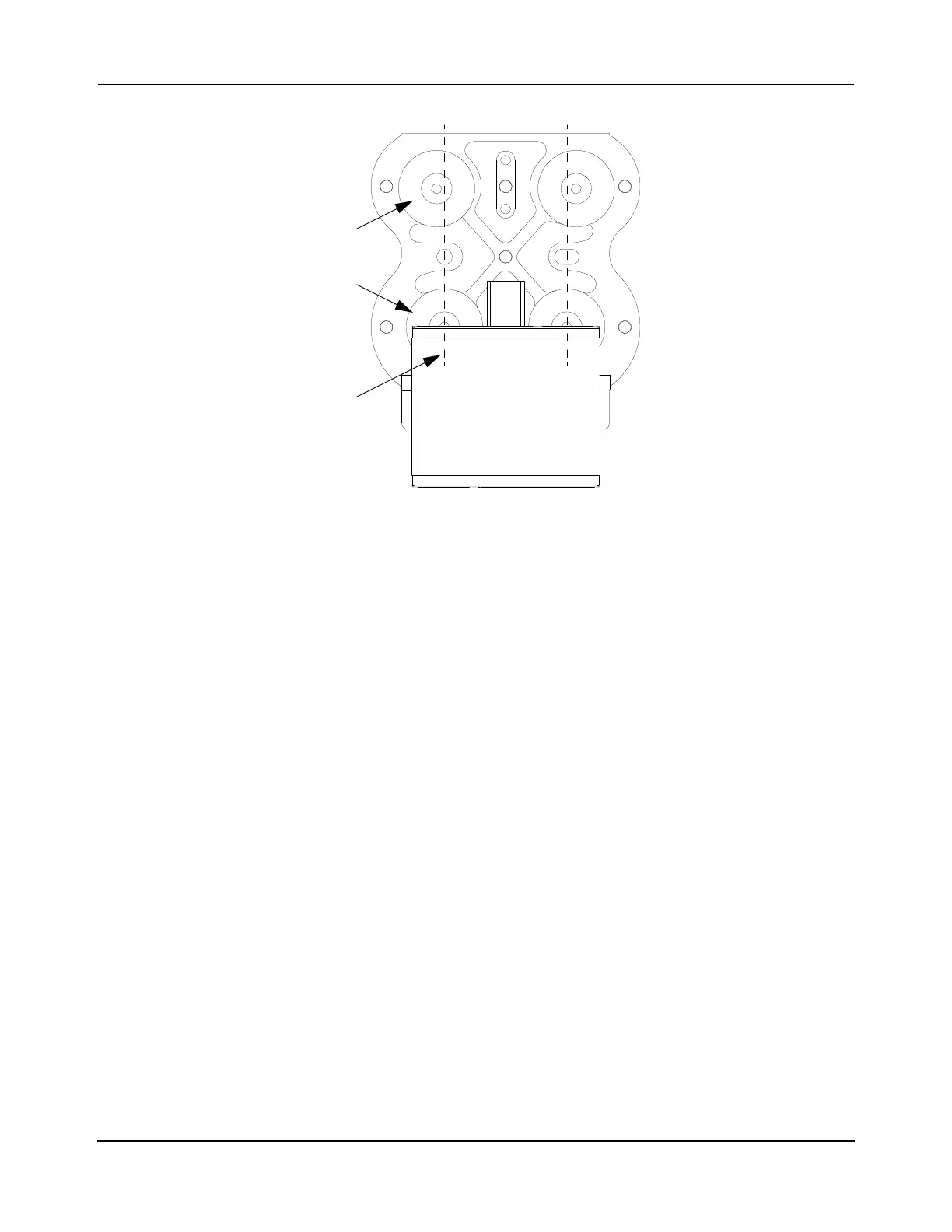

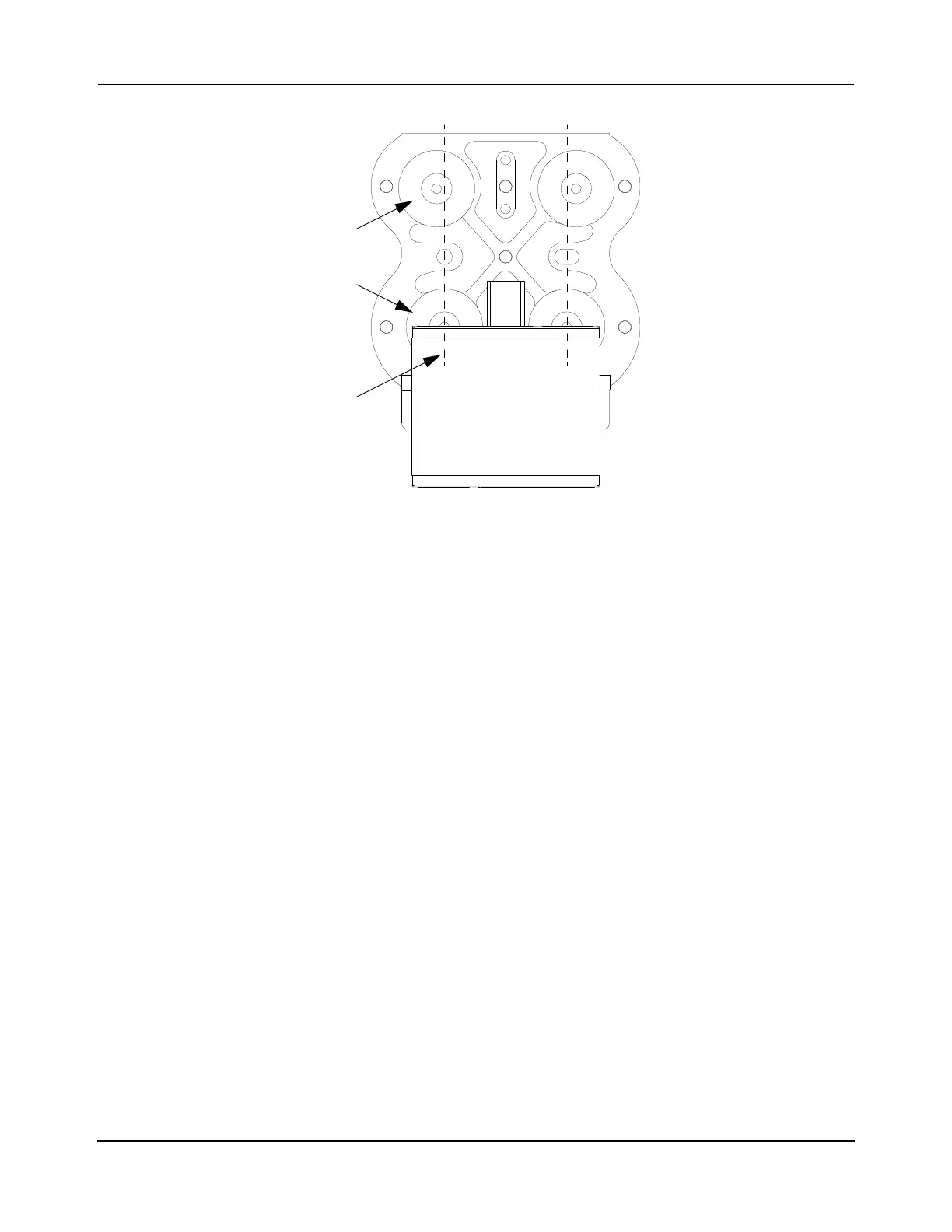

Figure 7-11: Eccentric Bearing Position

1. Stop all motion on the section of the MagneMover LITE transport system where the

vehicle is being adjusted.

2. Use a socket wrench and loosen the nut on the eccentric bearing to be adjusted on the

top of the vehicle (see Figure 7-10).

3. Use a thin open ended wrench and turn the bearing nut to rotate the eccentric bearing

either closer to (counter-clockwise) or further away from (clockwise) the rail.

4. Test the position of the bearing by moving the vehicle on the rail.

• If the vehicle can be rocked from side to side or front to back, rotate the bear-

ing CCW (closer to the rail) until the excess movement is minimized.

• If the vehicle does not move easily along the rail, rotate the bearing CW (fur-

ther away from the rail) until the binding is minimized.

5. Secure the bearing in place by holding the bearing nut firmly with a thin open ended

wrench while tightening the nut on the top of bearing to 19 N•m [14 ft•lb].

6. Apply Loctite 290 to the threads of the nut on the top of the carriage.

The Loctite must cure for 3 hours at 22° C [72° F] before using the vehicle.

Concentric Bearings

Eccentric Bearings

Concentric Bearing

Centerline

Loading...

Loading...