Maintenance

Repair

422 MagneMotion

Rockwell Automation Publication MMI-UM002F-EN-P - October 2022

7. Store the removed puck wrapped in bubble-wrap to help protect the puck and to mini-

mize any safety risks. Do not move one puck over, or near, the other puck.

8. Remove the remaining puck from the fixture and store it wrapped in bubble-wrap to

help protect the puck and to minimize any safety risks. Do not move one puck over, or

near, the other puck.

9. Service the pucks as required, see Replace Wheeled Puck Wear Surfaces, 2-Wheel

Pucks on page 416.

Reassemble Tandem Puck Assembly

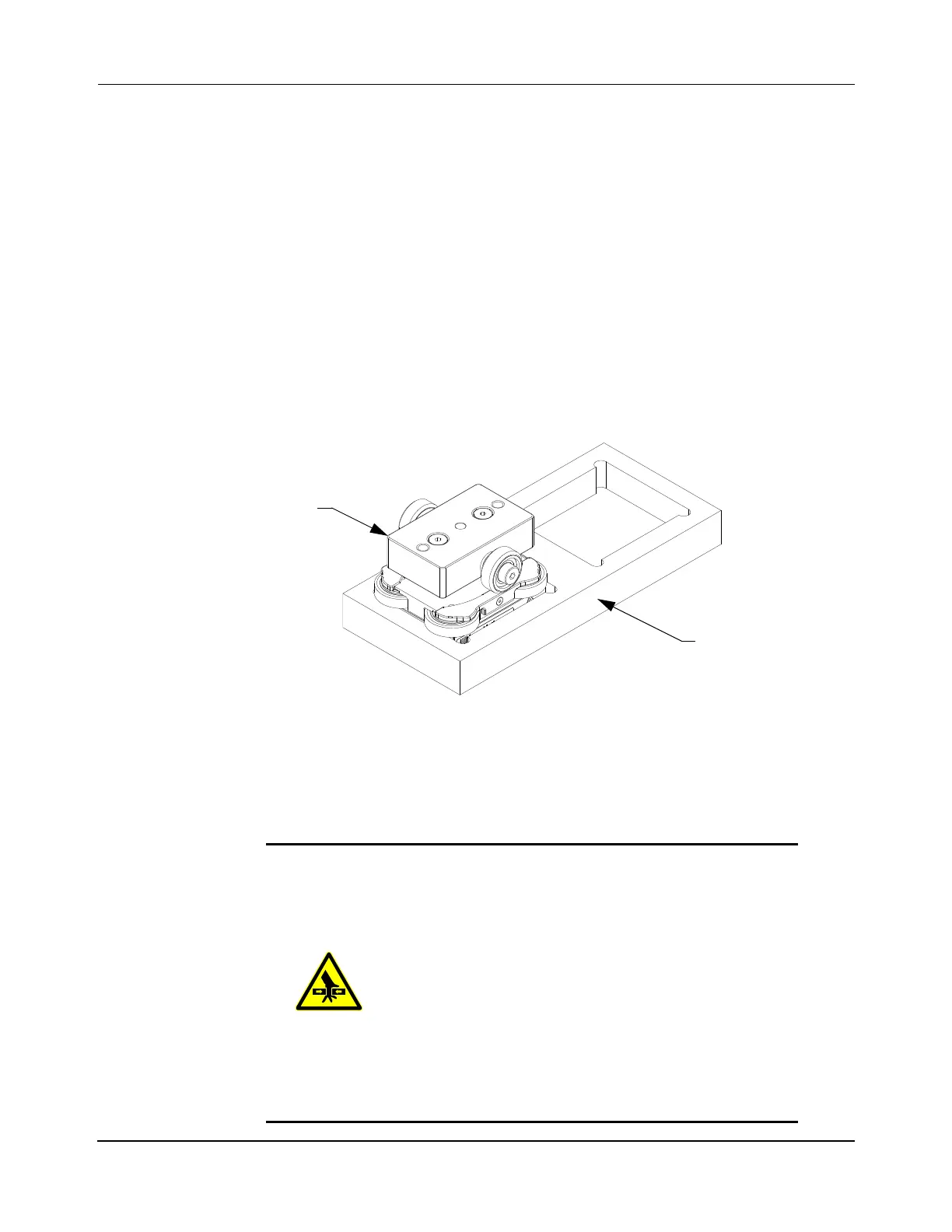

1. Place the tandem puck linkage plate installation fixture (shown in Figure 7-29) on a

flat surface.

2. Place one wheeled puck assembly in the left side of the fixture, see Figure 7-29.

Figure 7-29: Place First Wheeled Puck in Fixture

3. Hold the left wheeled puck in place and place the right wheeled puck in the fixture

keeping it as far away from the left puck as possible as shown in Figure 7-30. Do not

move one puck over, or near, the other puck.

PINCH/CRUSH HAZARD: Strong magnets in use.

To avoid injury from strong magnetic attractive

forces:

• Handle only one vehicle (puck) or magnet array at

a time.

• Do not place any body parts (for example, fingers)

between a magnet array and any ferrous material

or another magnet array.

• Vehicles (pucks) and magnet arrays not being used

must be secured individually in isolated packag-

ing.

Loading...

Loading...