Teach-in | Turning cycles

5

HEIDENHAIN | MANUALplus 620 | User's Manual | 12/2017

217

Cutting, transverse plunge

Select Roughing cycles lon/trans

Select Plunge transv.

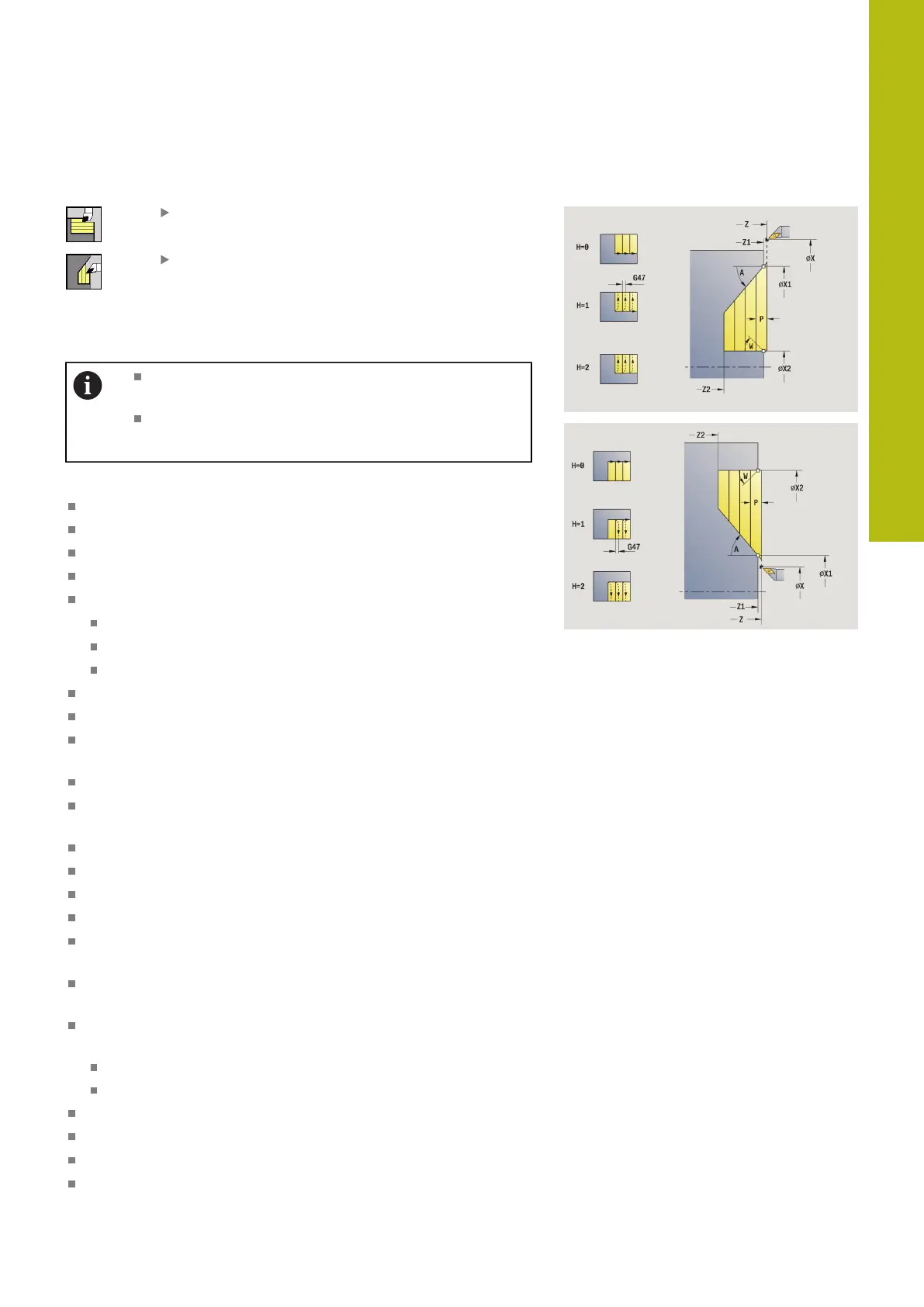

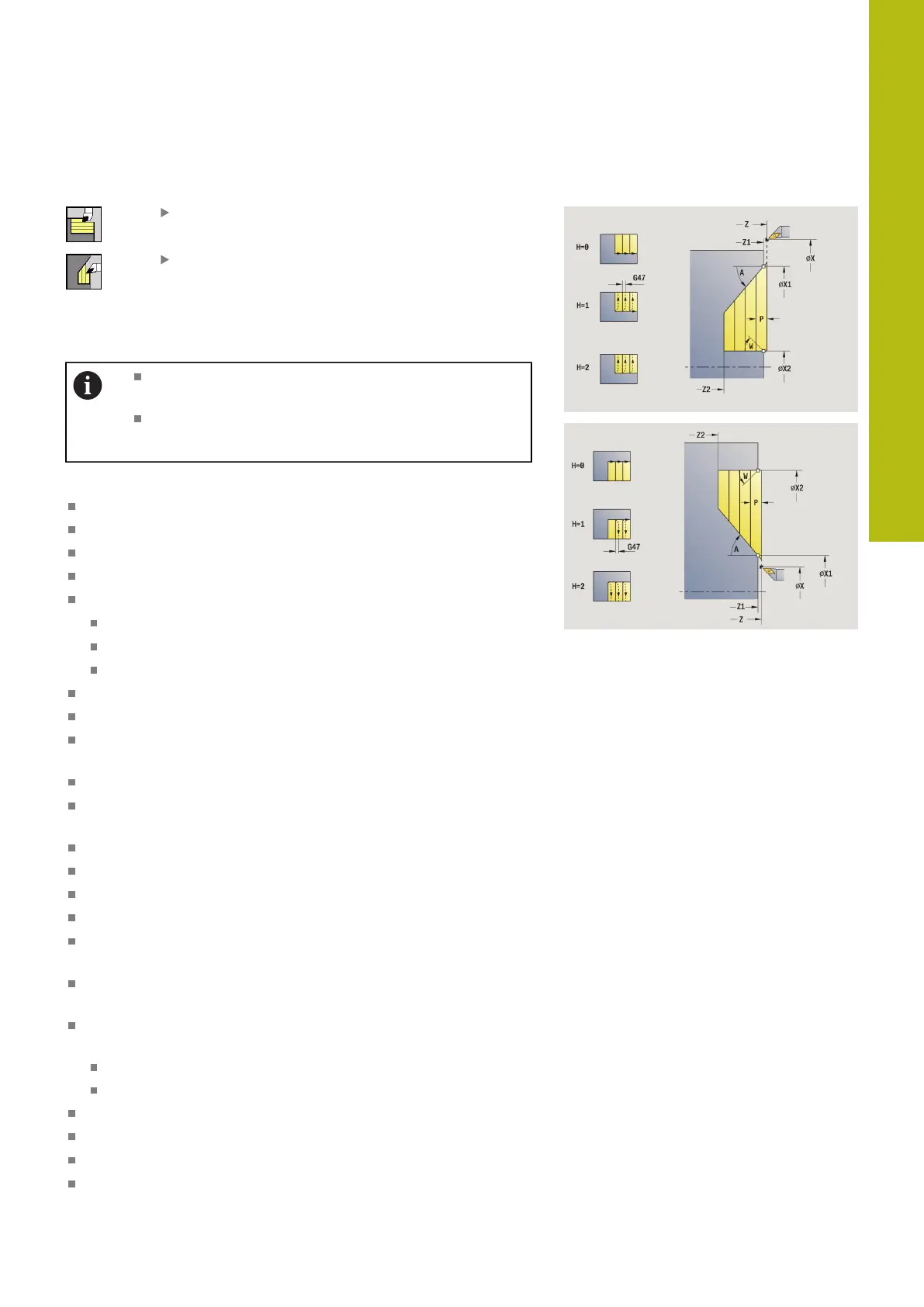

The cycle roughs the area described by the Start point contour,

End point contour and Plunging angle.

The tool plunges with the maximum possible angle,

leaving material remaining

The steeper the tool plunges into the material, the

greater the feed rate decrease (max. 50 %)

Cycle parameters:

X, Z: Start point

X1, Z1: Start point contour

X2, Z2: End point contour

P: Feed depth – Maximum infeed depth

H: Contour smoothing

0: With each cut

1: With the last cut

2: No smoothing

A: Plunging angle (range: 0° <= A < 90°; default: 0°)

W: Final angle (range: 0° <= W < 90°; default: 0°)

G47: Safety clearance

Further information: "Safety clearance G47", Page 180

T: Tool number – turret pocket number

G14: Tool change point

Further information: "Tool change point G14", Page 180

ID: ID no.

S: Cutting speed or Constant speed

F: Feed per revolution

MT: M after T: M function that is executed after the tool call T

MFS: M at beginning: M function that is executed at the

beginning of the machining step

MFE: M at end: M function that is executed at the end of the

machining step

WP: No. of spindle – Displays which workpiece spindle is used

to execute the cycle (machine-dependent)

Main drive

Opposing spindle for rear-face machining

BW: Angle in the B axis (machine-dependent)

CW: Reverse the tool (machine-dependent)

HC: Shoe brake (machine-dependent)

DF: Miscellaneous function (machine-dependent)

Loading...

Loading...