Teach-in | Milling cycles

5

HEIDENHAIN | MANUALplus 620 | User's Manual | 12/2017

391

Engraving, axial

Engraving, axial

Select Milling

Select Engraving

Select Engraving, axial

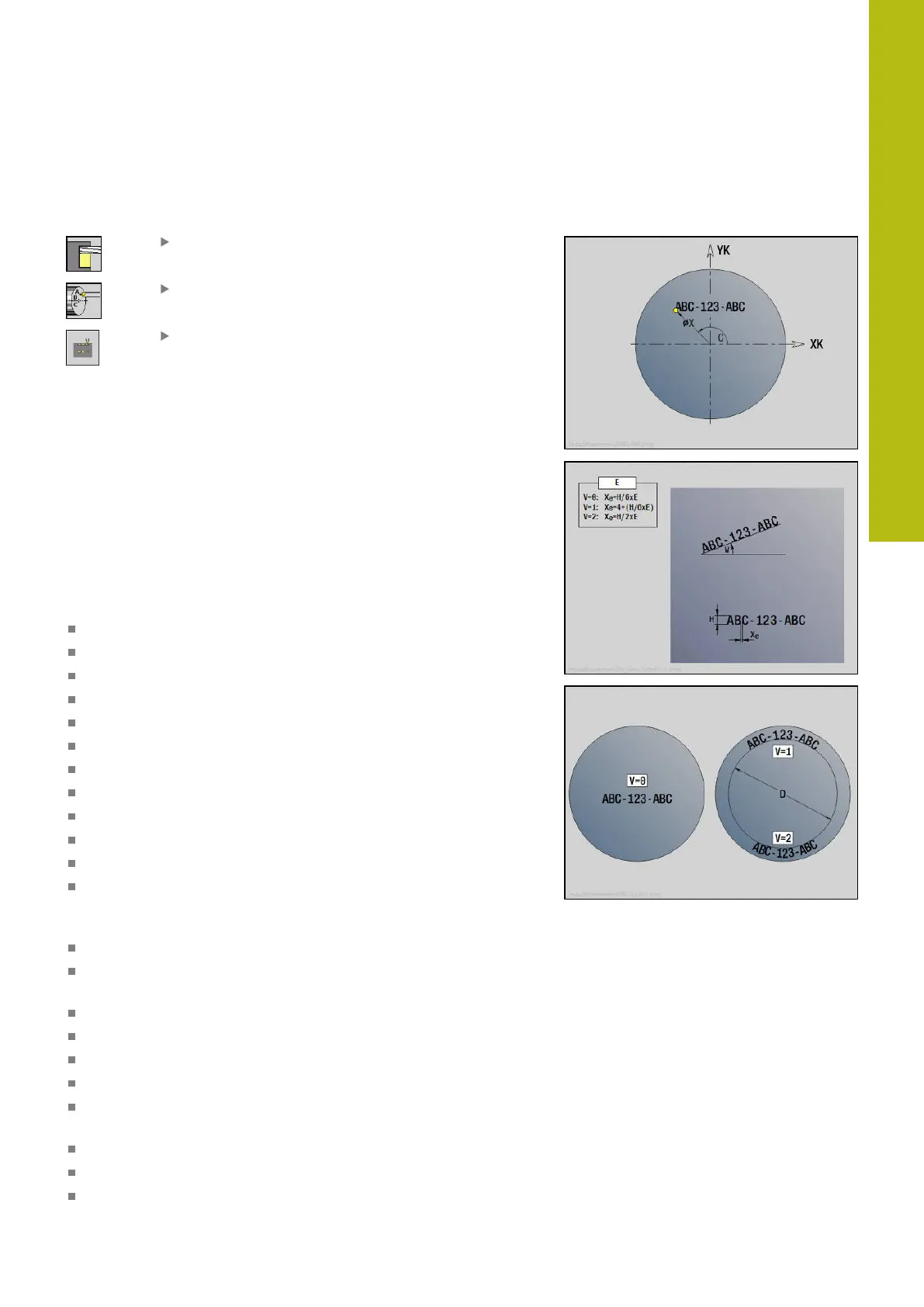

The Engraving, axial cycle engraves character strings in linear or

polar layout on the face of the workpiece.

Character set and more information:

Further information: "Engraving, axial and radial", Page 395

You define the Start point of the character string in the cycle. If

you do not define a Start point, the cycle starts at the current tool

position.

You can also engrave a logotype with several calls. For this

purpose, specify the Start point with the first call. All other calls

are programmed without a Start point.

Cycle parameters:

X: Starting point – Pre-positioning the tool (diameter value)

Z: Starting point – Pre-positioning the tool

C: Spindle angle – Pre-positioning the workpiece spindle

TX: Text to be engraved

NF: Char. no. – ASCII code of the character to be engraved

Z2: Final point – Z position, infeed depth during engraving

X1: Start point of first character (polar)

C1: Start. angle (polar) of first character

XK: Start point of first character (Cartesian)

YK: Start point of first character (Cartesian)

H: Font height

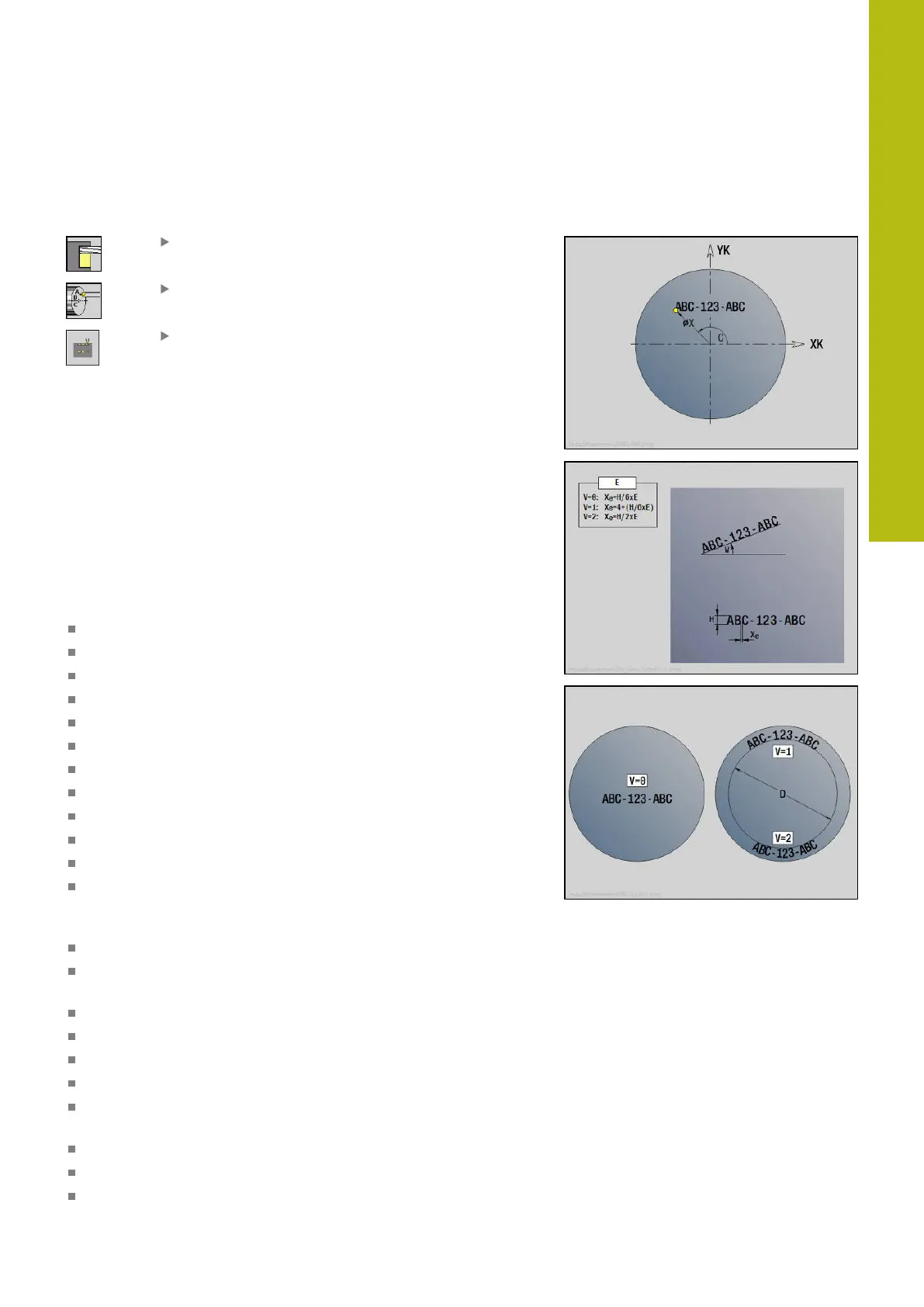

E: Distance factor (calculation: see figure)

The distance between the characters is calculated according to

the following formula: H / 6 * E

T: Tool number – turret pocket number

G14: Tool change point

Further information: "Tool change point G14", Page 180

ID: ID no.

S: Cutting speed or Constant speed

F: Feed per revolution

W: Inclinat. ang. of the character string

FZ: Plunging feed rate factor (plunging feed rate = current feed

rate * FZ)

V: Execution (linear/polar)

D: Reference diameter

RB: Return plane – Z position retracted to for positioning

Loading...

Loading...