Teach-in | Turning cycles

5

HEIDENHAIN | MANUALplus 620 | User's Manual | 12/2017

239

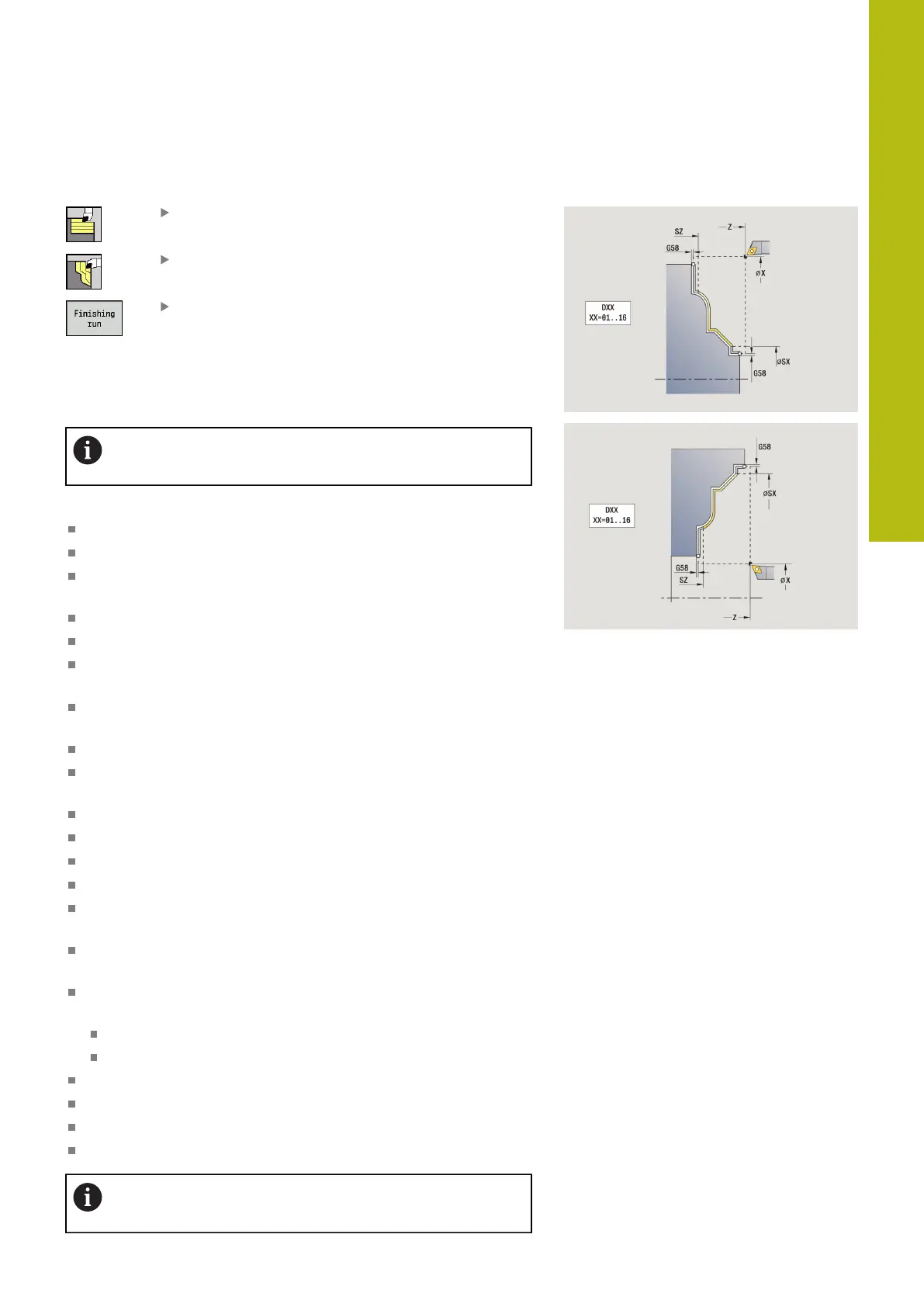

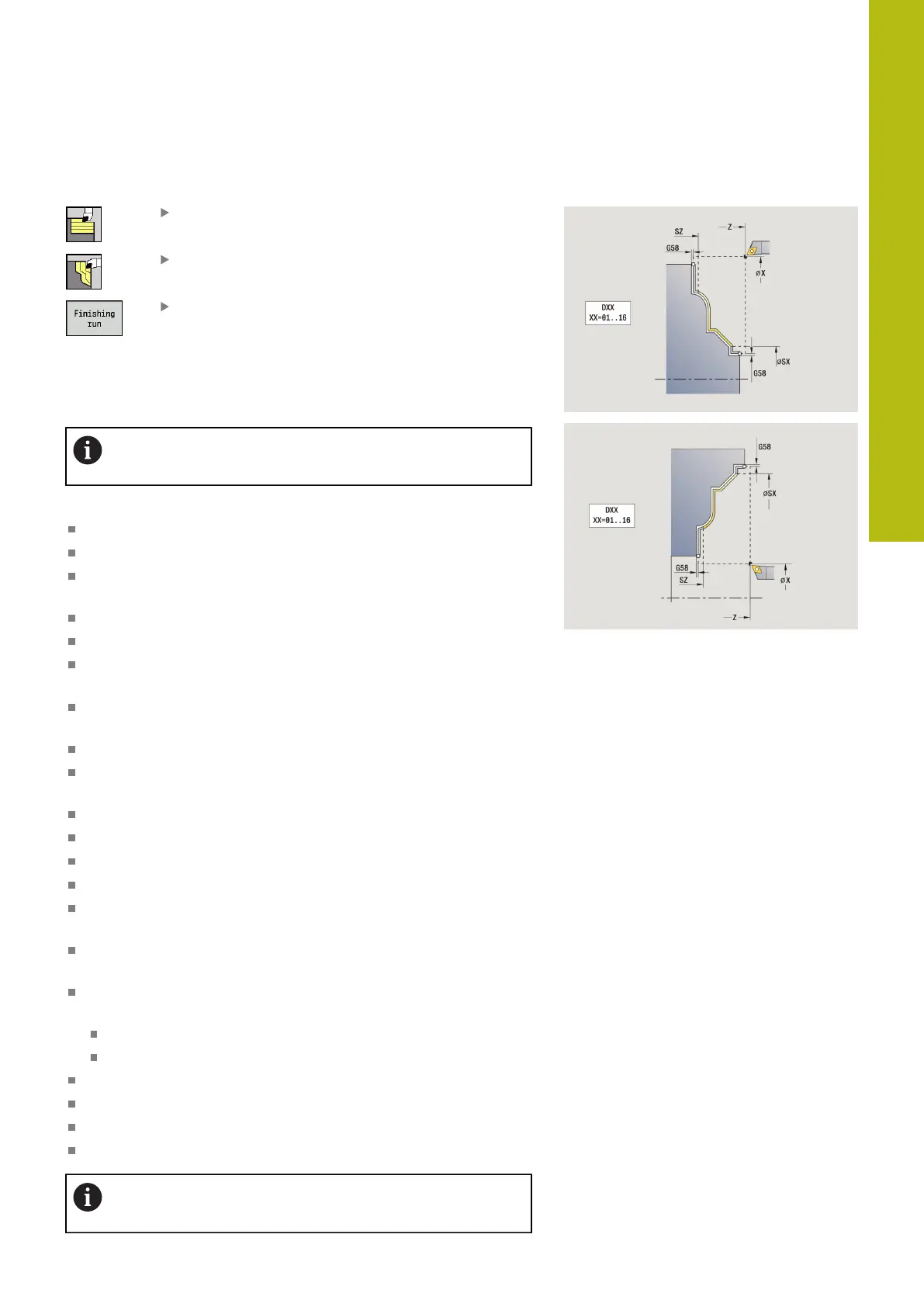

Cutting, transverse, ICP contour-parallel, finishing

Select Roughing cycles lon/trans

Select ICP transv. parallel contour

Press the Finishing run soft key

The cycle finishes the contour area defined by the ICP contour.

When the cycle is completed, the tool remains at the cycle end

position.

The tool plunges with the maximum possible angle,

leaving material remaining.

Cycle parameters:

X, Z: Start point

FK: No. of ICP finished part – name of contour to be machined

DXX: Add. correction number (range: 1 to 16)

Further information: "Additive compensation Dxx", Page 180

G58: Contour-parallel oversize

DI, DK: Oversize X and Z axis-parallel

SX, SZ: Cutting limit in X and Z

Further information: "Cutting limits SX, SZ", Page 180

G47: Safety clearance

Further information: "Safety clearance G47", Page 180

T: Tool number – turret pocket number

G14: Tool change point

Further information: "Tool change point G14", Page 180

ID: ID no.

S: Cutting speed or Constant speed

F: Feed per revolution

MT: M after T: M function that is executed after the tool call T

MFS: M at beginning: M function that is executed at the

beginning of the machining step

MFE: M at end: M function that is executed at the end of the

machining step

WP: No. of spindle – Displays which workpiece spindle is used

to execute the cycle (machine-dependent)

Main drive

Opposing spindle for rear-face machining

BW: Angle in the B axis (machine-dependent)

CW: Reverse the tool (machine-dependent)

HC: Shoe brake (machine-dependent)

DF: Miscellaneous function (machine-dependent)

Type of machining for technology database access:

Finishing

Loading...

Loading...