Teach-in | Drilling cycles

5

HEIDENHAIN | MANUALplus 620 | User's Manual | 12/2017

357

Axial thread milling

Select Drilling

Select Axial thread milling

The cycle mills a thread in existing holes.

Use threading tools for this cycle.

Cycle parameters:

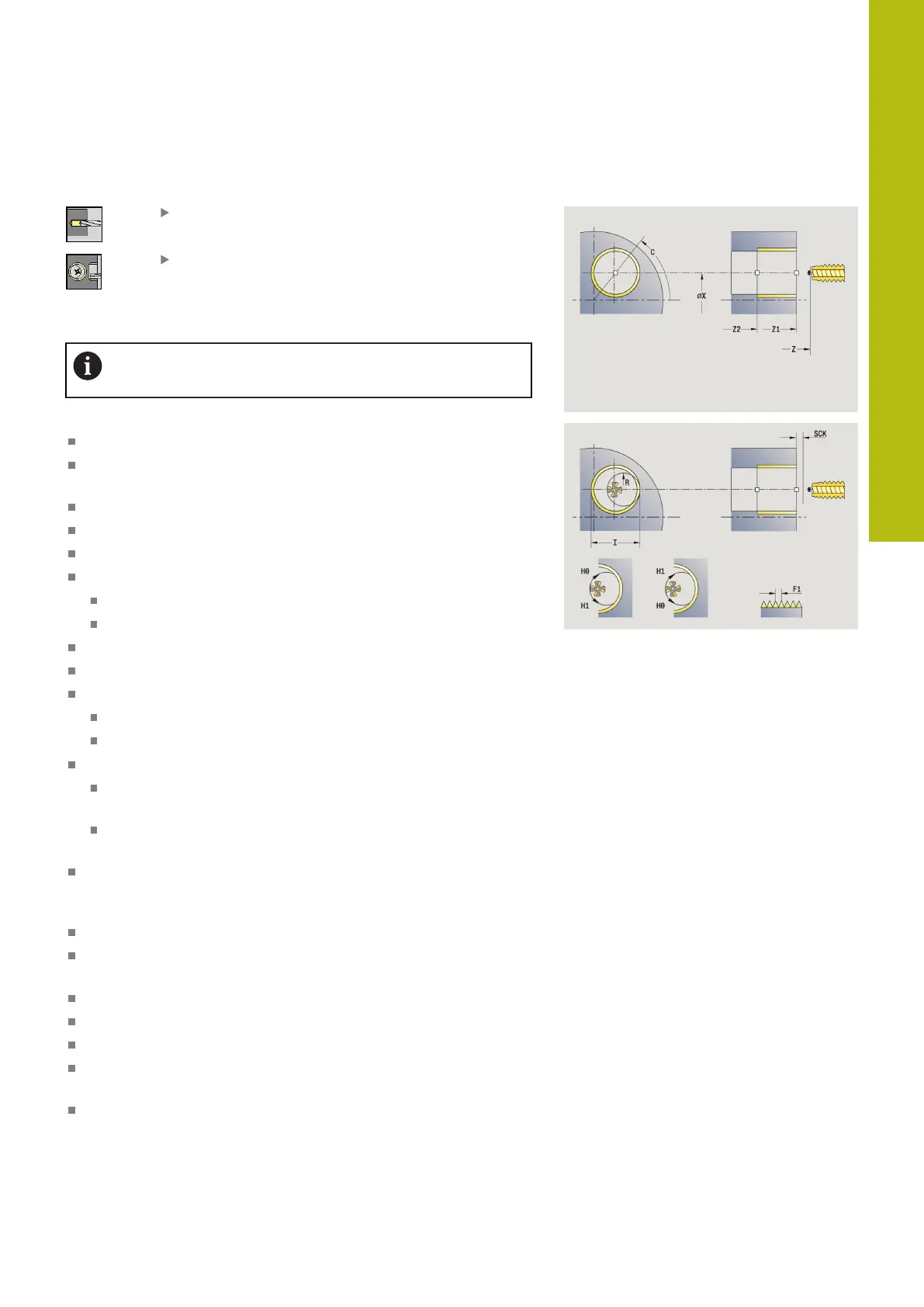

X, Z: Start point

C: Spindle angle – C-axis position (default: current spindle

angle)

Z1: Start point drill (default: drilling starts from Z)

Z2: End point drill

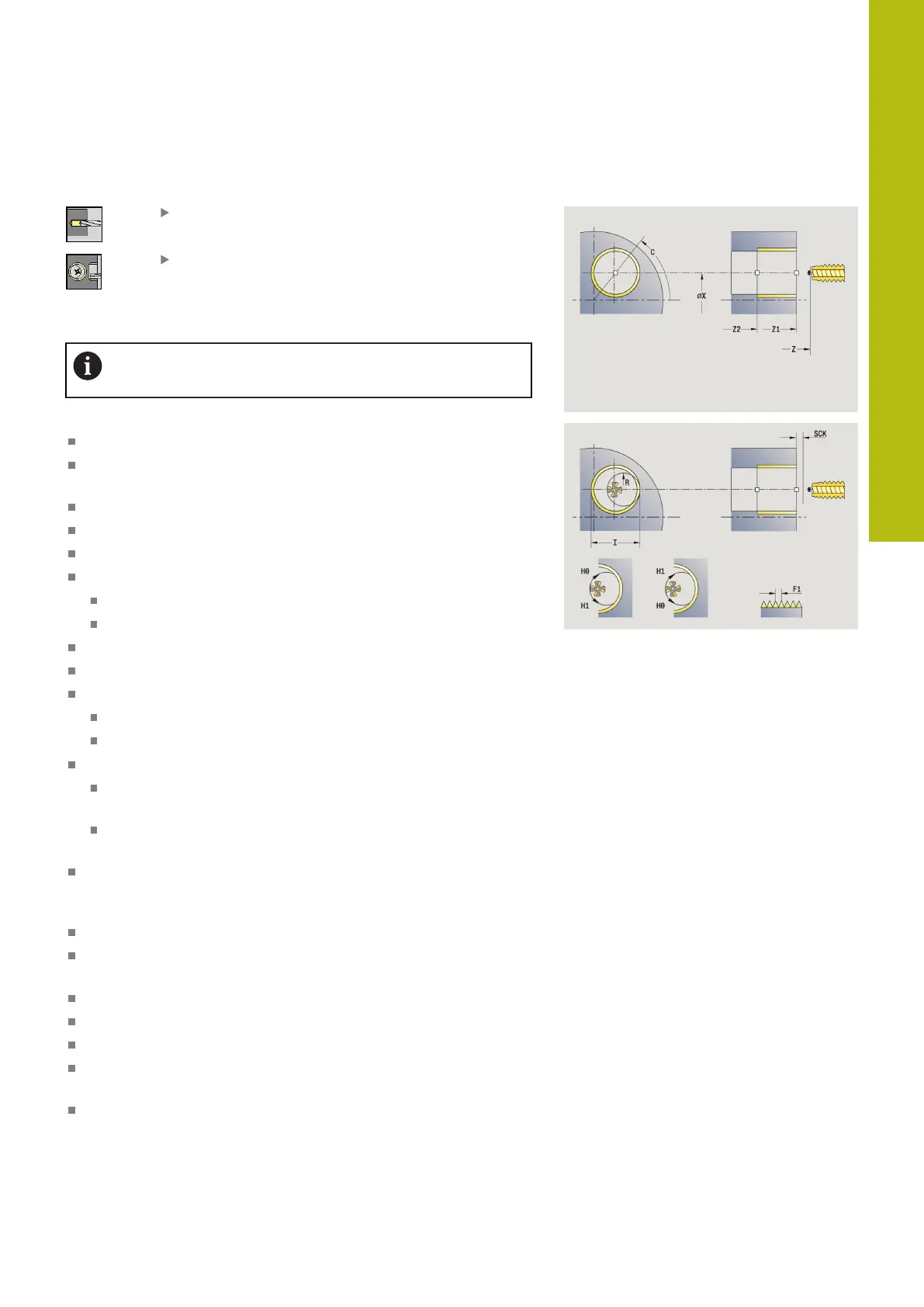

F1: Thread pitch (= feed rate)

J: Direction of thread:

0: Right-hand thread

1: Left-hand thread

I: Thread diameter

R: Approach radius (default: (I – milling diameter)/2)

H: Mill cutting direction

0: Up-cut

1: Climb

V: Milling method

0: One revolution – the thread is milled in a 360-degree

helix

1: Two or more revolutions – the thread is milled in several

helix paths (single-point tool)

SCK: Safety clearance

Further information: "Safety clearances SCI and SCK",

Page 180

T: Tool number – turret pocket number

G14: Tool change point

Further information: "Tool change point G14", Page 180

ID: ID no.

S: Cutting speed or Constant speed

MT: M after T: M function that is executed after the tool call T

MFS: M at beginning: M function that is executed at the

beginning of the machining step

MFE: M at end: M function that is executed at the end of the

machining step

Loading...

Loading...