Teach-in | Turning cycles

5

HEIDENHAIN | MANUALplus 620 | User's Manual | 12/2017

231

Cutting, longitudinal, ICP contour-parallel

Select Roughing cycles lon/trans

Select ICP-long.parallel contour

The cycle roughs the defined area on contour-parallel paths.

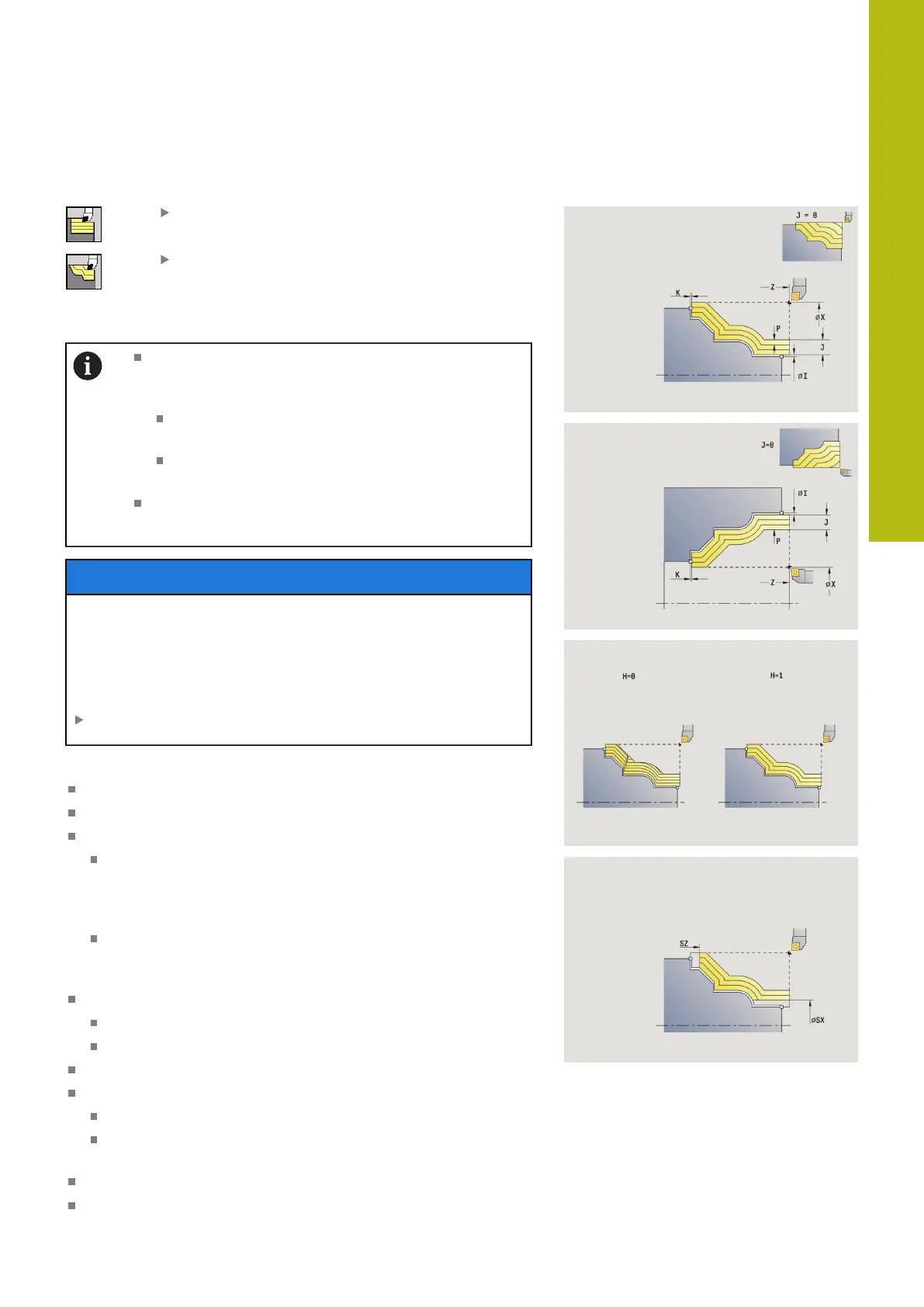

The cycle roughs contour parallel depending on the

Workpiece blank oversize J and the Type of cut

lines H:

J = 0: The area defined by X, Z and the ICP

contour, taking the oversizes into account

J > 0: The area defined by the ICP contour (plus

oversizes) and the Workpiece blank oversize J

The tool plunges with the maximum possible angle,

leaving material remaining

NOTICE

Danger of collision!

If Workpiece blank oversize J is > 0, the control does not

check whether the programmed Feed depth P is possible with

the current cutting geometry in the transverse and longitudinal

directions. There is danger of collision during machining!

Select a Feed depth P that fits the current cutting geometry

Cycle parameters:

X, Z: Start point

FK: No. of ICP finished part – name of contour to be machined

P: Feed depth (is determined taking J into account)

J = 0: P is the maximum infeed depth.

The cycle reduces the infeed depth if the programmed

infeed is not possible in the transverse or longitudinal

direction due to the cutting geometry.

J > 0: P is the infeed depth.

This infeed is used in the longitudinal and transverse

directions.

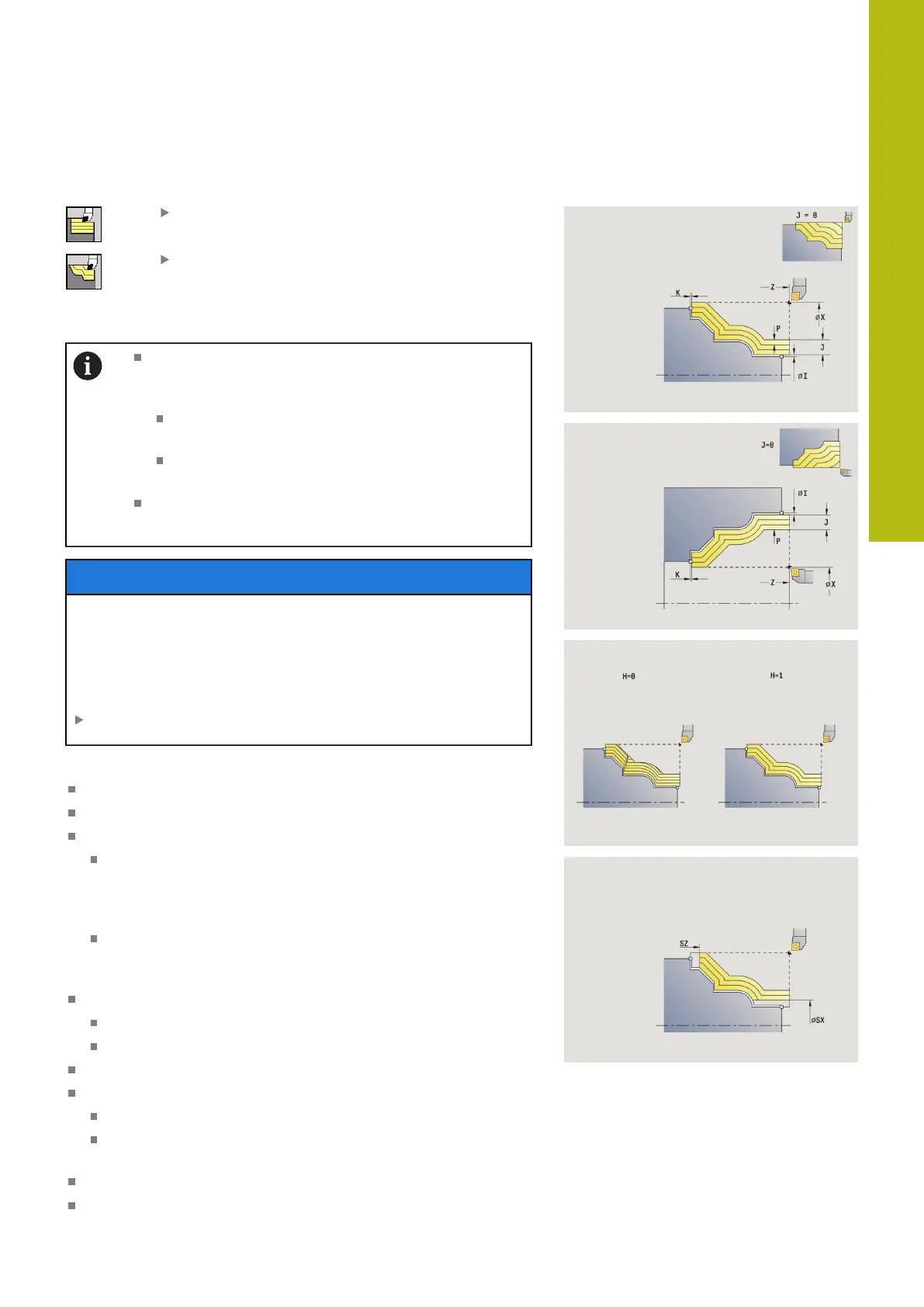

H: Type of cut lines – The cycle machines

0: Constant mach.depth

1: Equidistant cut lines

I, K: O-size X and Z

J: Workpiece blank oversize

J = 0: The cycle machines from the current tool position

J > 0: The cycle machines the area defined by the workpiece

blank oversize

HR: Main machining direction

SX, SZ: Cutting limit in X and Z

Further information: "Cutting limits SX, SZ", Page 180

Loading...

Loading...