Teach-in | Thread and undercut cycles

5

338

HEIDENHAIN | MANUALplus 620 | User's Manual | 12/2017

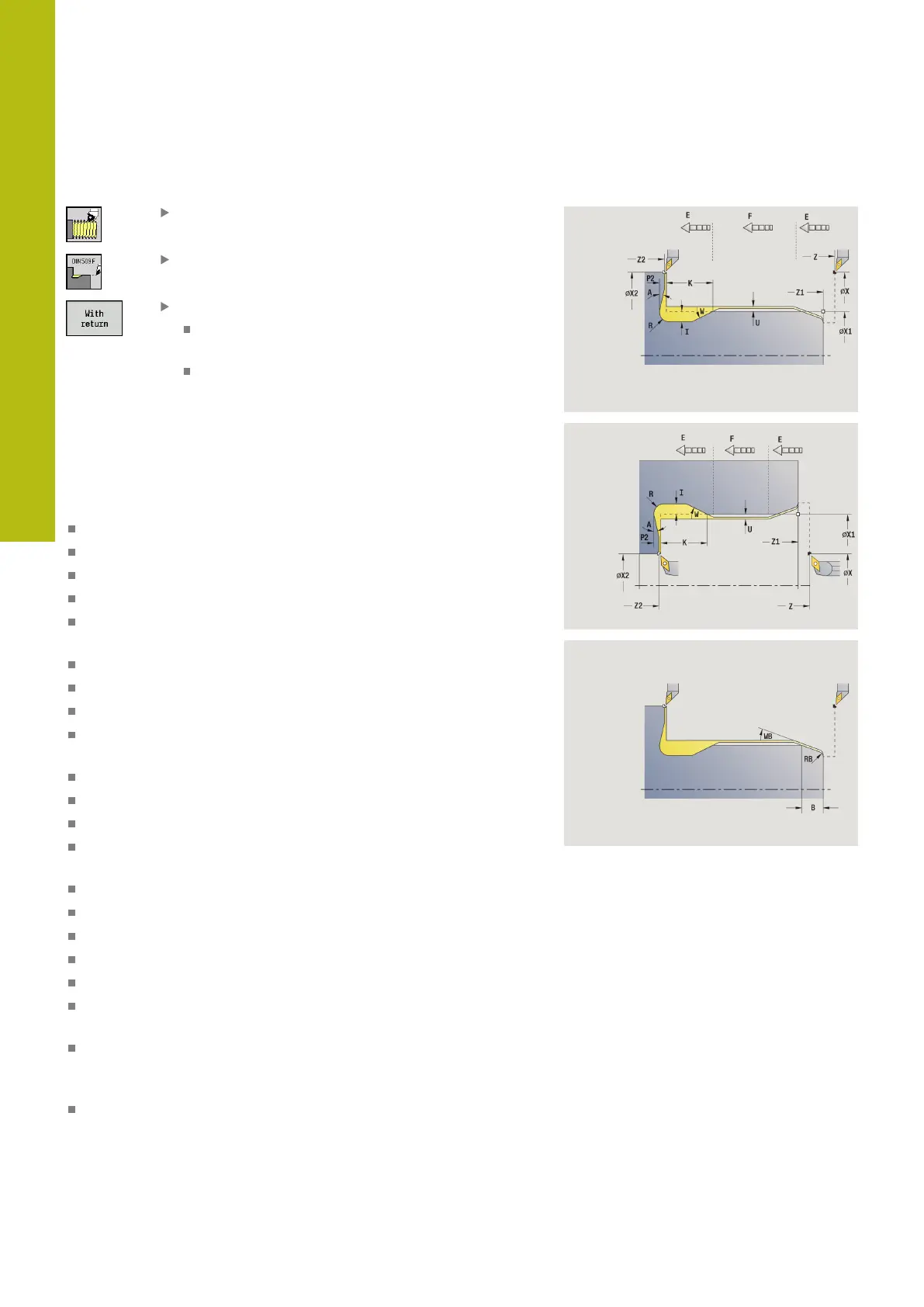

Undercut DIN 509 F

Select Thread cutting

Undercut DIN 509 F

Select the scope of the cycle:

Off: When the cycle is completed, the tool

remains at the cycle end position

On: The tool returns to the starting point

The cycle machines an Undercut DIN 509 F, a cylinder start

chamfer, then the adjoining cylinder, and finishes with the plane

surface. You can define a finishing oversize for the area of the

cylinder. The cylinder chamfer is executed when you enter at least

one of the parameters Cylinder 1st cut length or Cut-in radius.

Cycle parameters:

X, Z: Start point

X1, Z1: Start point cylinder

X2, Z2: End point transv.

U: Grind. overs. for the area of the cylinder (default: 0)

E: Reduced feed for the plunge cut and the thread chamfer

(default: Feed per revolution F)

I: Undercut depth (default: standard table)

K: Undercut length (default: standard table)

W: Undercut angle (default: standard table)

R: Undercut radius on both sides of the undercut (default: value

from standard table)

P2: Surf. depth (default: standard table)

A: Face angle (default: standard table)

T: Tool number – turret pocket number

G14: Tool change point

Further information: "Tool change point G14", Page 180

ID: ID no.

S: Cutting speed or Constant speed

F: Feed per revolution

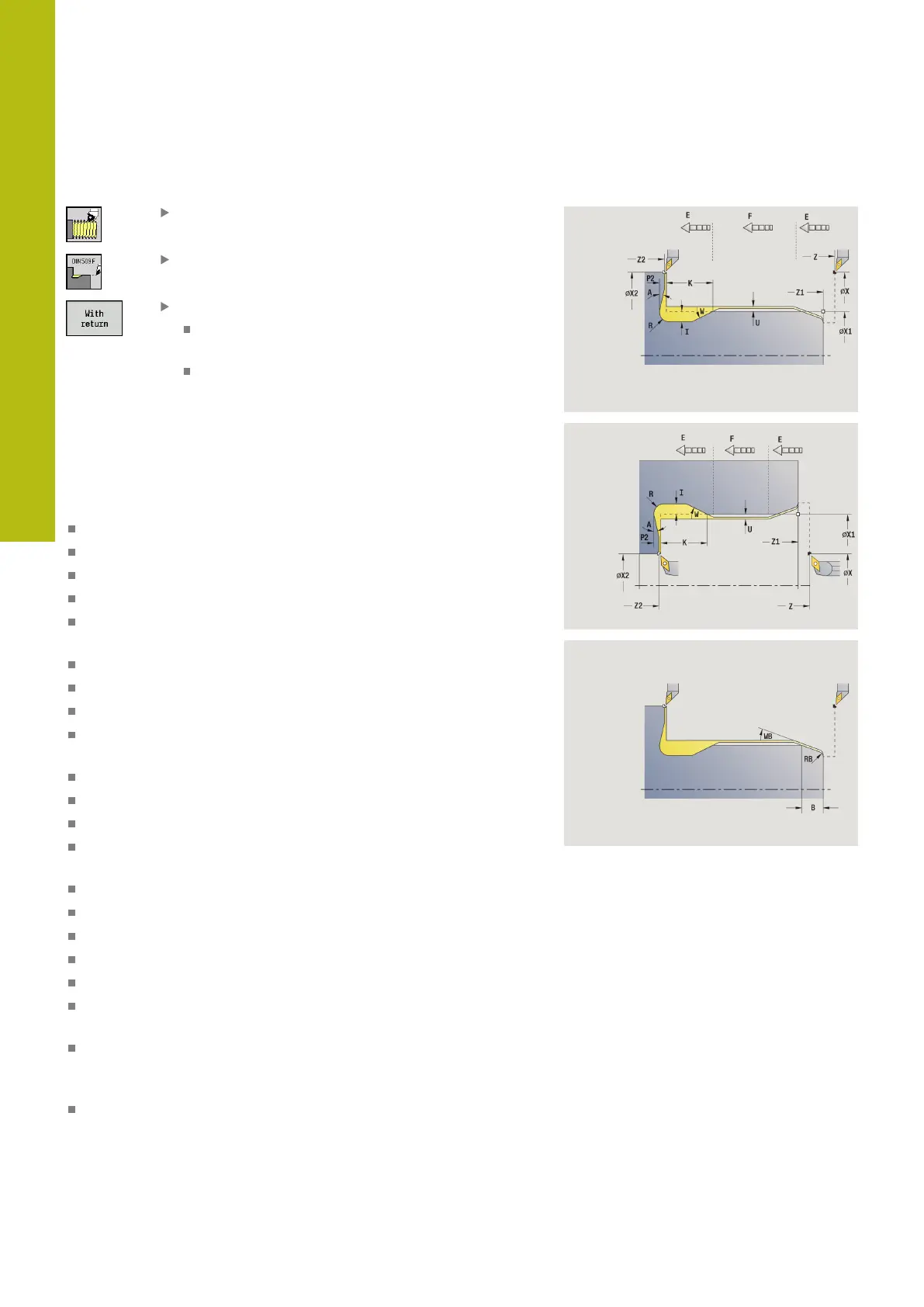

B: Cylinder 1st cut length (default: no start chamfer)

WB: Cut-in angle (default: 45°)

RB: Cut-in radius (no input: no element, positive value: first cut

radius, negative value: chamfer)

G47: Safety clearance

Further information: "Safety clearance G47", Page 180 —

evaluated only if With return is active

MT: M after T: M function that is executed after the tool call T

Loading...

Loading...