Teach-in | Recessing cycles

5

HEIDENHAIN | MANUALplus 620 | User's Manual | 12/2017

253

5.5 Recessing cycles

Menu item Meaning

The recessing cycle group compris-

es recessing, recess turning, undercut

and parting cycles. Simple contours are

machined in basic mode, complex contours

in expanded mode.

ICP recessing cycles machine contours defined with ICP.

Further information: "ICP contours", Page 416

Proportioning of cuts: The control calculates a

constant recessing width that is <= P

Oversizes are considered in expanded mode

Tool-tip radius compensation is conducted

(exception: Undercut type K)

Cutting and infeed directions for recessing cycles:

The control determines the cutting and infeed directions from the

cycle parameters.

The decisive ones are:

Basic mode: The parameters for Starting point X, Z (in

Machine mode: current tool position) and Start point contour

X1 / End point contour Z2

Expanded mode: The parameters for Start point contour X1,

Z1 and End point contour X2, Z2

ICP cycles: The parameters for Starting point X, Z (in Machine

mode: current tool position) and starting point of ICP contour

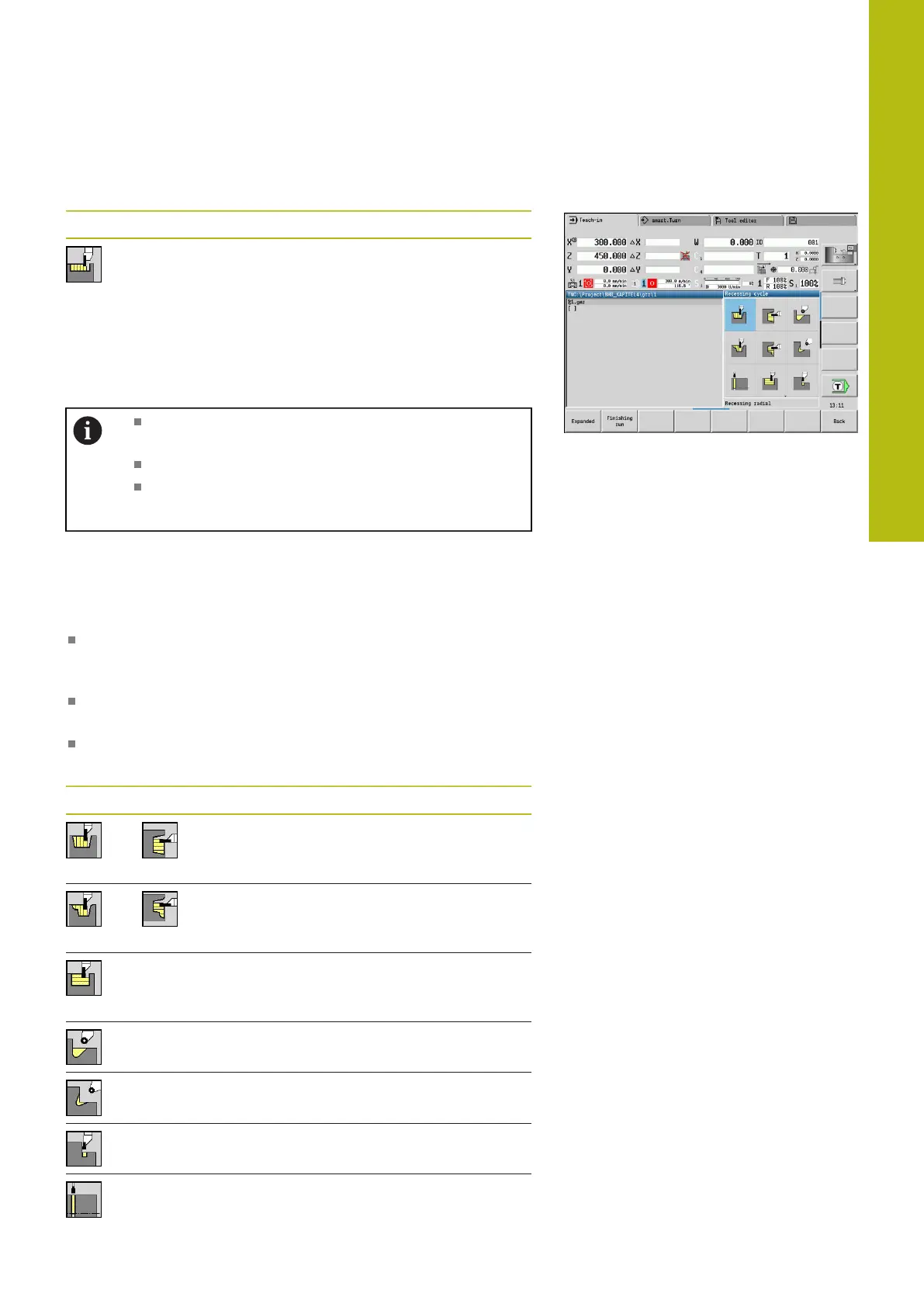

Menu item Recessing cycles

Recessing radial/Recessing axial

Recessing and finishing cycles for simple

contours

ICP recessing radial/ICP recessing axial

Recessing and finishing cycles for any

contour

Recess turning radial/Recess turning axial

Recess-turning and finishing cycles for

simple contours and any type of contour

Undercut. Form H

Undercut type H

Undercut. Form K

Undercut type K

Undercut. Form U

Undercut type U

Cut-off

Cycle for parting the workpiece

Loading...

Loading...