Engine Mechanical: 1D-69

• Tighten the crankcase breather (PCV) cover bolts.

Engine Top Side

Assemble the engine top side. Refer to “Engine Top Side

Disassembly” (Page 1D-26).

Cylinder Inspection

B947H11406033

Refer to “Engine Top Side Disassembly” (Page 1D-26).

Refer to “Engine Top Side Assembly” (Page 1D-28).

Cylinder Distortion

Check the gasket surface of the cylinder for distortion.

Use a straightedge and thickness gauge. Take clearance

readings at several places. If any reading exceeds the

service limit, replace the crankcase set.

Special tool

: 09900–20803 (Thickness gauge)

Cylinder distortion

Service limit: 0.02 mm (0.0008 in)

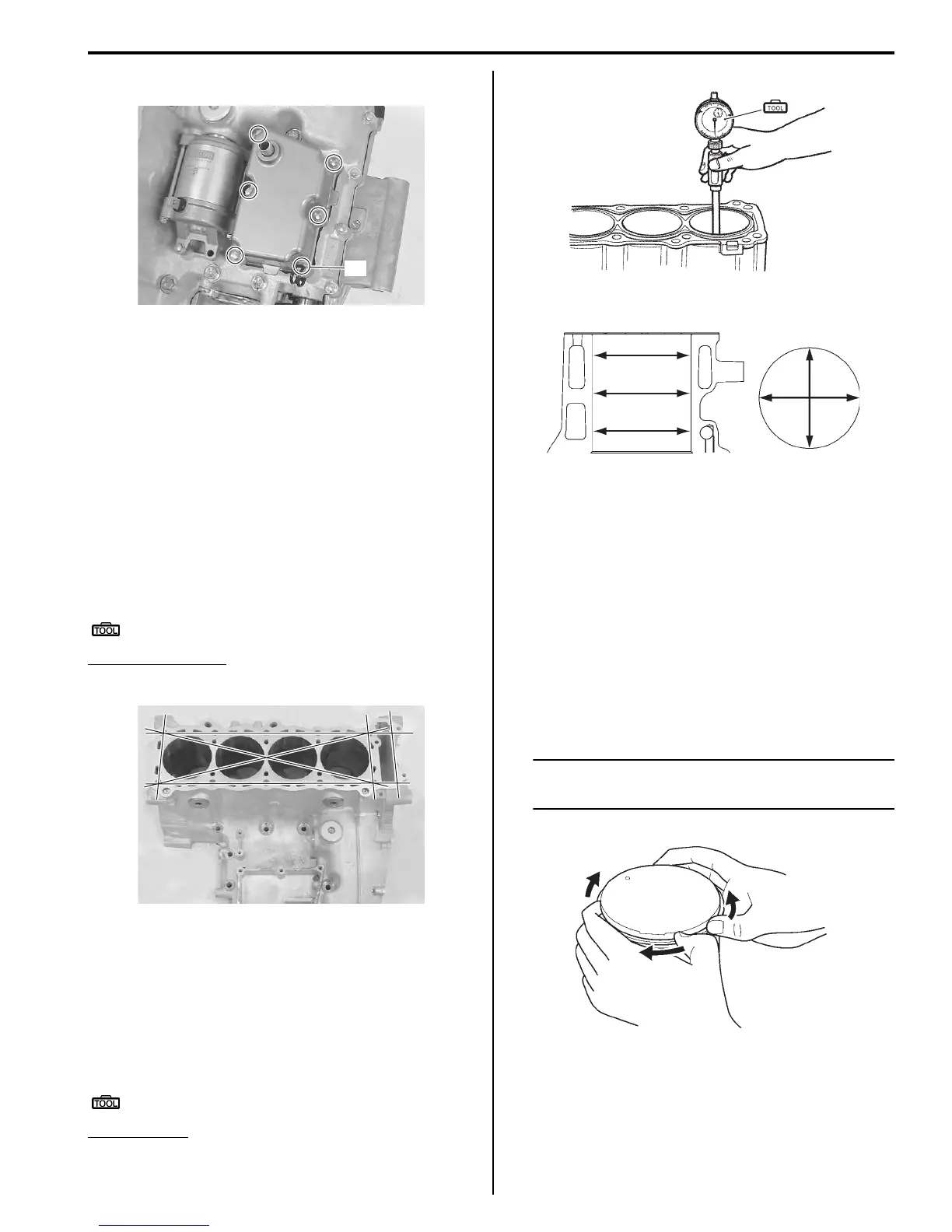

Cylinder Bore

Measure the cylinder bore diameter at six places. If any

one of the measurements exceed the limit, overhaul the

cylinder and replace the piston with an oversize piston.

The remaining cylinders must also be rebored

accordingly; otherwise, the imbalance might cause

excessive vibration.

Special tool

(A): 09900–20530 (Cylinder gauge set)

Cylinder bore

Standard: 74.500 – 74.515 mm (2.9331 – 2.9337 in)

Piston-to-cylinder Clearance

Refer to “Piston and Piston Ring Inspection” (Page 1D-

71).

Piston Ring Removal and Installation

B947H11406034

Removal

1) Remove the piston. Refer to “Engine Bottom Side

Disassembly” (Page 1D-49).

2) Carefully spread the ring opening with your thumbs

and then push up the opposite side of the 1st ring to

remove it.

NOTE

Do not expand the piston ring excessively

since it is apt to be broken down.

3) Remove the 2nd ring and oil ring in the same

manner.

“A”

I947H1140215-03

I947H1140216-01

(A)

I947H1140217-02

I837H1140180-01

I837H1140181-01

Manuals by Motomatrix / The Solution For Lost Motorcycle Coded Keys

email: info@motomatrix.co.uk / www.motomatrix.co.uk

Loading...

Loading...