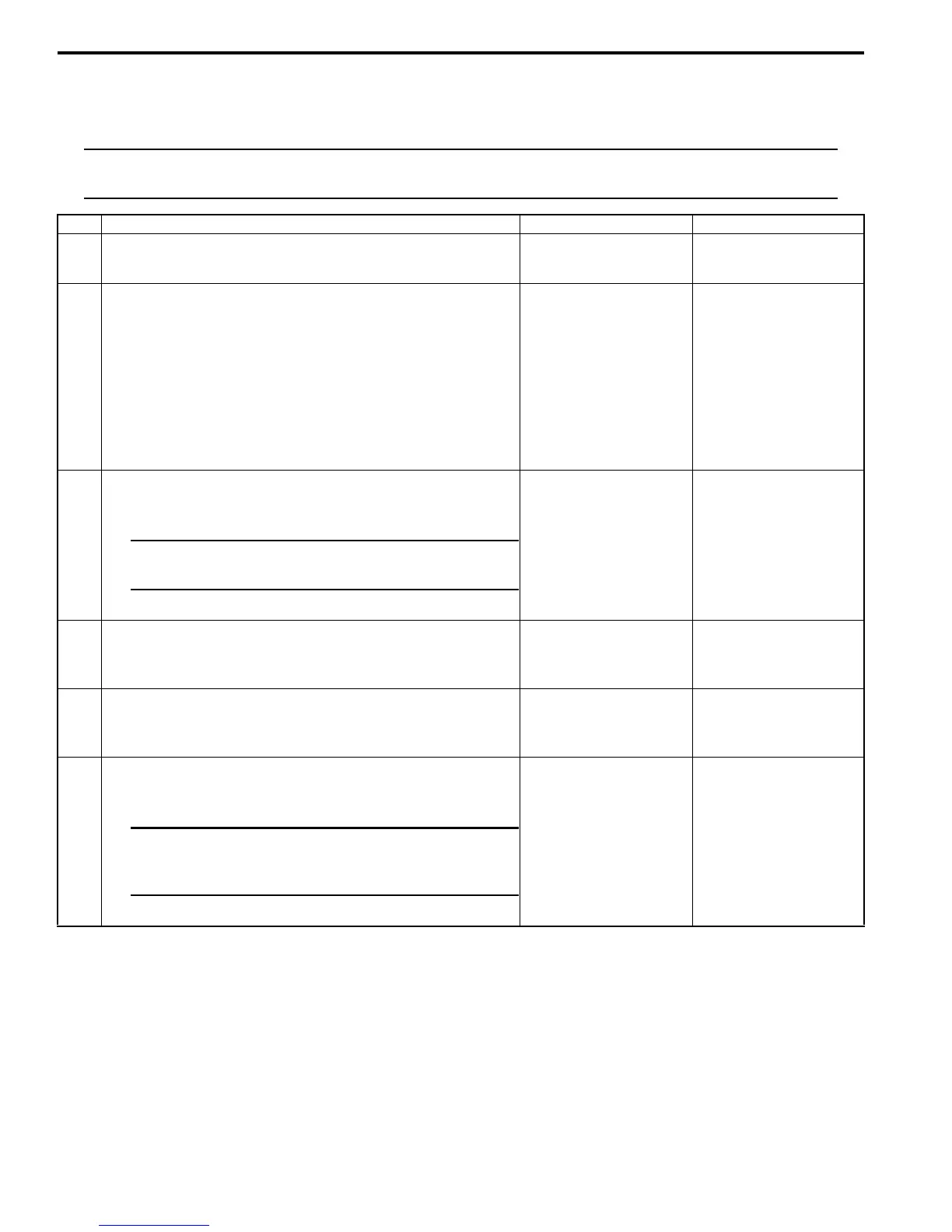

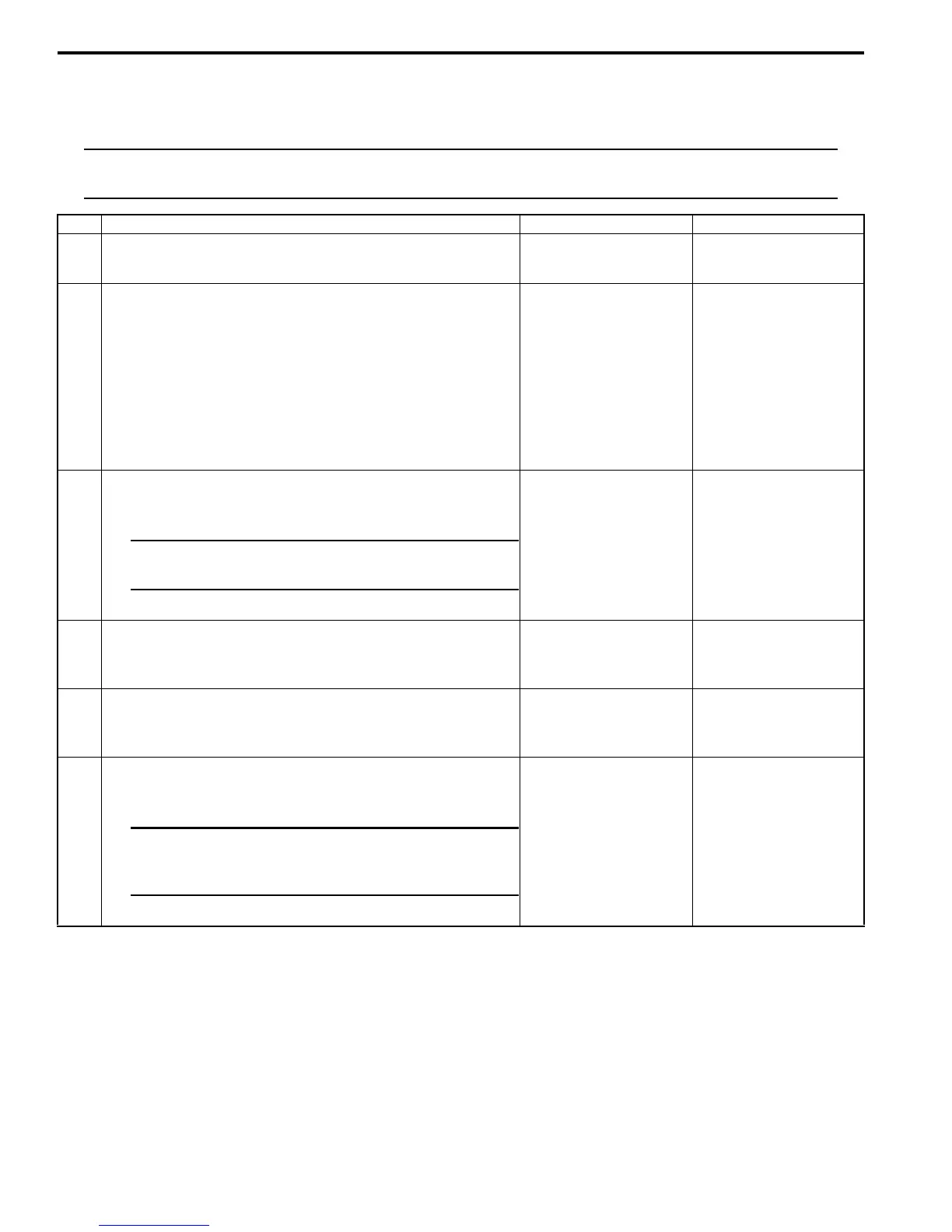

1H-5 Ignition System:

No Spark or Poor Spark

B947H11804002

Troubleshooting

NOTE

Check that the transmission is in neutral and the engine stop switch is in the “RUN” position. Grasp

the clutch lever. Check that the fuse is not blown and the battery is fully-charged before diagnosing.

Step Action Yes No

1 Check the ignition system couplers for poor connections.

Is there connection in the ignition system couplers?

Go to Step 2. Poor connection of

couplers.

2 Measure the battery voltage between input lead wires at the

ECM with the ignition switch in the “ON” position. (E-02, 19,

24, 51: O/G and B/W, E-03, 14, 28, 33: O/W and B/W)

Is the voltage OK?

Go to Step 3. • Faulty ignition switch.

• Faulty turn signal/

side-stand relay.

• Faulty engine stop

switch.

• Broken wire harness

or poor connection of

related circuit

couplers.

3 Measure the ignition coil primary peak voltage. Refer to

“Ignition Coil Inspection” (Page 1H-7).

NOTE

This inspection method is applicable only with

the multi-circuit tester and the peak volt adaptor.

Is the peak voltage OK?

Go to Step 4. Go to Step 5.

4 Inspect the spark plugs. Refer to “Spark Plug Inspection and

Cleaning” in Section 0B (Page 0B-9).

Is the spark plug(-s) OK?

Go to Step 5. Faulty spark plug(-s).

5 Inspect the ignition coil. Refer to “Ignition Coil Inspection”

(Page 1H-7).

Is the ignition coil OK?

Go to Step 6. • Faulty ignition coil.

• Poor connection of

the ignition coil.

6 Measure the CKP sensor peak voltage and its resistance.

Refer to “CKP Sensor Inspection” (Page 1H-9).

NOTE

The CKP sensor peak voltage inspection is

applicable only with the multi-circuit tester and

peak volt adaptor.

Are the peak voltage and resistance OK?

•Faulty ECM.

• Open or short circuit

in wire harness.

• Poor connection of

ignition couplers.

• Faulty CKP sensor.

• Metal particles or

foreign material being

stuck on the CKP

sensor and rotor tip.

Manuals by Motomatrix / The Solution For Lost Motorcycle Coded Keys

email: info@motomatrix.co.uk / www.motomatrix.co.uk

Loading...

Loading...