5B-12 Manual Transmission:

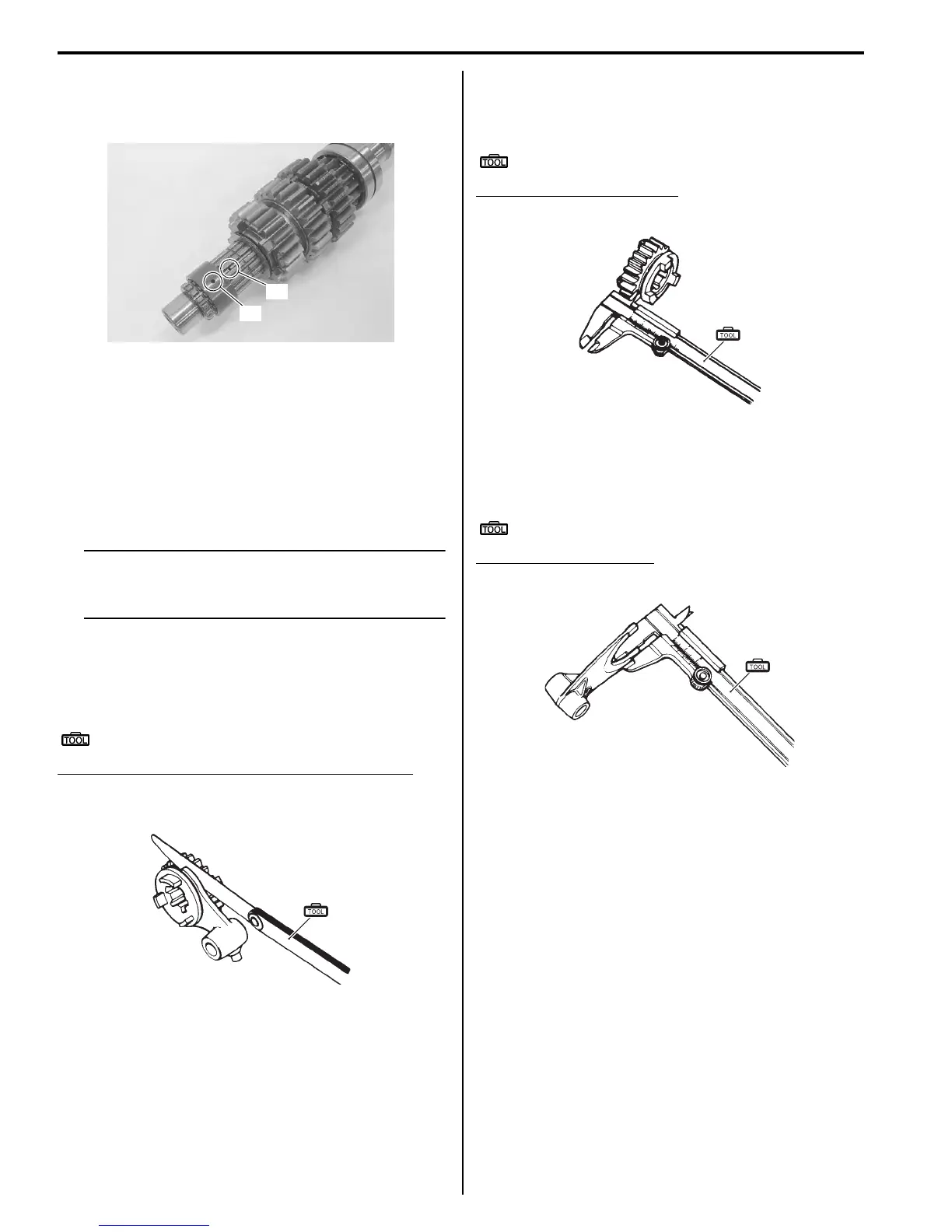

• When installing the gear bushing onto the

countershaft, align the shaft oil hole “A” with the

bushing oil hole “B”.

Transmission Related Parts Inspection

B947H15206006

Refer to “Transmission Removal” (Page 5B-3),

“Transmission Installation” (Page 5B-5) and

“Countershaft Gear / Driveshaft Gear Disassembly and

Assembly” (Page 5B-10).

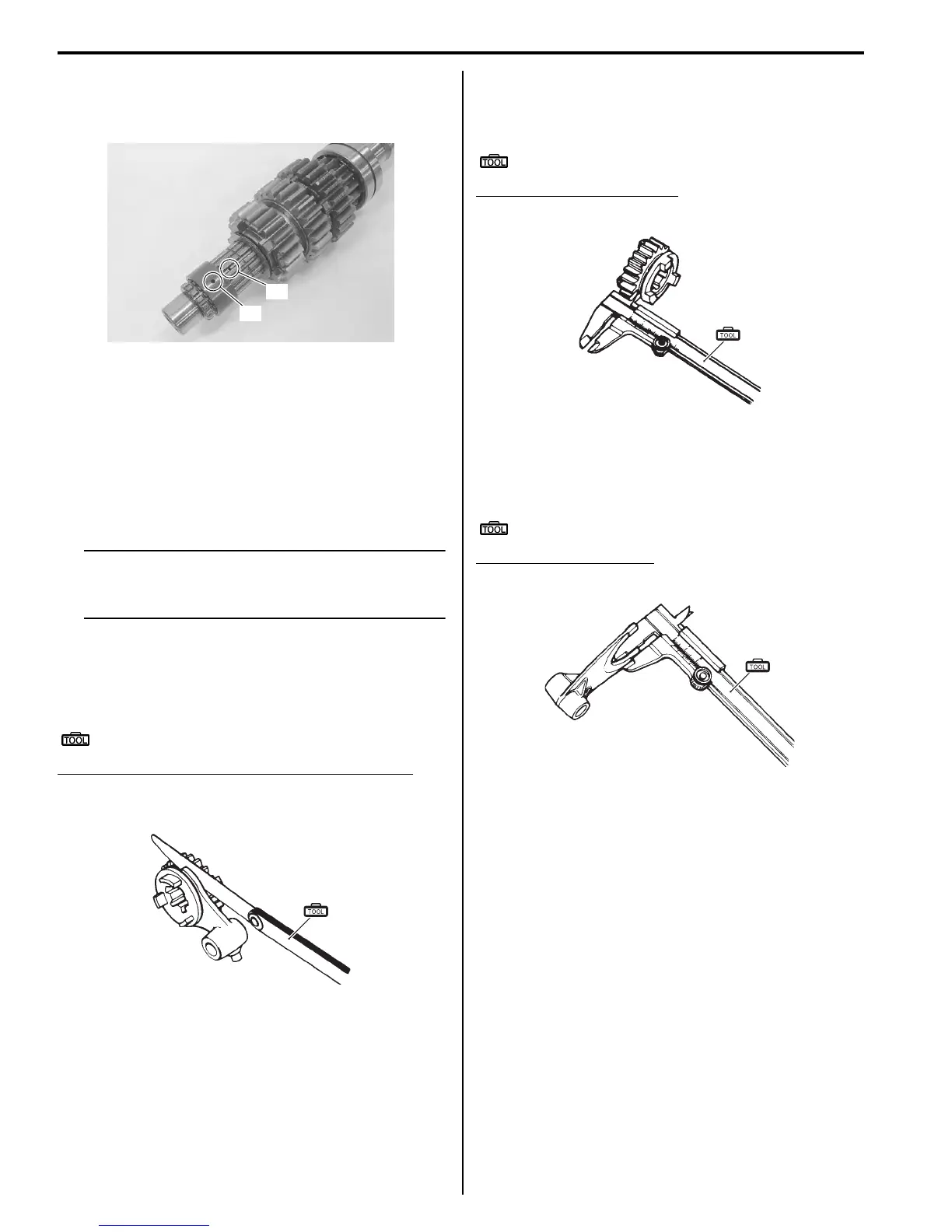

Gearshift Fork to Groove Clearance

NOTE

The clearance for each gearshift fork plays

an important role in the smoothness and

positiveness of the shifting action.

Using the thickness gauge, check the gearshift fork

clearance in the groove of its gear.

If the clearance checked is noted to exceed the limit

specified, replace the fork or its gear, or both.

Special tool

(A): 09900–20803 (Thickness gauge)

Gearshift fork to gearshift fork groove clearance

Standard: 0.1 – 0.3 mm (0.004 – 0.012 in)

Service limit: 0.5 mm (0.02 in)

Gearshift Fork Groove Width

Measure the gearshift fork groove width using the

vernier calipers.

Special tool

(A): 09900–20102 (Vernier calipers (200 mm))

Gearshift fork groove width

Standard: 5.0 – 5.1 mm (0.197 – 0.201 in)

Gearshift Fork Thickness

Measure the gearshift fork thickness using the vernier

calipers.

Special tool

(A): 09900–20102 (Vernier calipers (200 mm))

Gearshift fork thickness

Standard: 4.8 – 4.9 mm (0.189 – 0.193 in)

“A”

“B”

I947H1520067-01

(A)

I649G1520056-03

(A)

I649G1520057-03

(A)

I649G1520058-03

Manuals by Motomatrix / The Solution For Lost Motorcycle Coded Keys

email: info@motomatrix.co.uk / www.motomatrix.co.uk

Loading...

Loading...