1D-78 Engine Mechanical:

Conrod Crank Pin Bearing Inspection and

Selection

B947H11406042

Refer to “Engine Bottom Side Disassembly” (Page 1D-

49).

Refer to “Engine Bottom Side Assembly” (Page 1D-56).

Inspection

1) Inspect the bearing surfaces for any signs of fusion,

pitting, burn or flaws. If any, replace them with a

specified set of bearings.

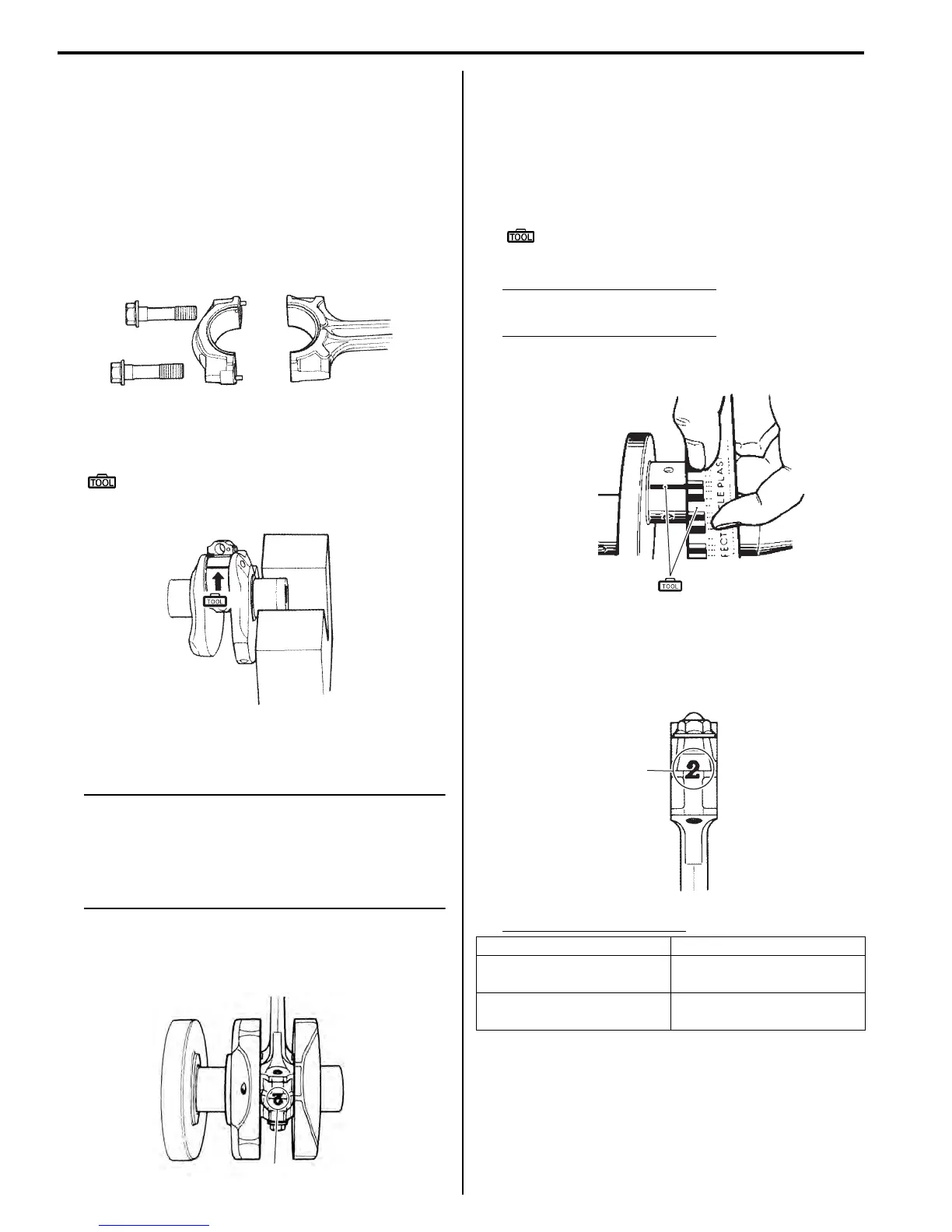

2) Place the plastigauge axially along the crank pin,

avoiding the oil hole, as shown in the figure.

Special tool

(A): 09900–22301 (Plastigage (0.025 – 0.076

mm))

3) Tighten the conrod cap bolts to the specified torque,

in two stages.

NOTE

• When installing the conrod cap bolts to the

crank pin, make sure that I.D code “A” on

the conrod faces towards the intake side.

• Never rotate the crankshaft or conrod

when a piece of plastigauge is installed.

Tightening torque

Conrod cap bolt: 37 N⋅m (3.7 kgf-m, 26.5 Ib-ft)

then turn in 1/6 (60°) turn

4) Remove the conrod cap bolts and measure the width

of the compressed plastigauge using the envelope

scale. This measurement should be taken at the

widest part of the compressed plastigauge.

If the oil clearance exceeds the service limit, select

the specified bearings from the bearing selection

table.

Special tool

(A): 09900–22301 (Plastigage (0.025 – 0.076

mm))

Conrod big end oil clearance

Standard: 0.040 – 0.064 mm (0.0016 – 0.0025 in)

Conrod big end oil clearance

Service limit: 0.080 mm (0.0031 in)

Selection

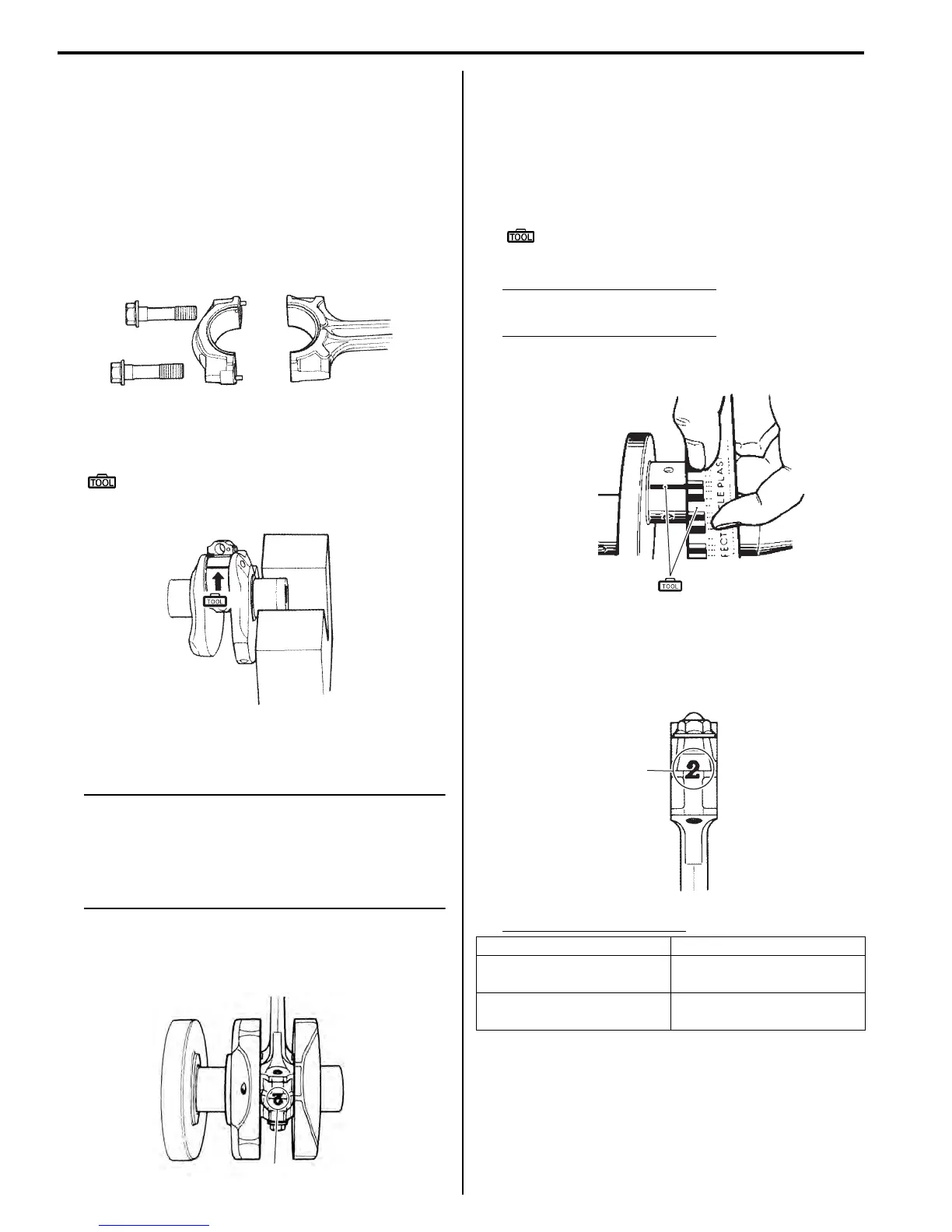

1) Check the corresponding conrod I.D. code numbers

([1] or [2]) “A”.

Conrod I.D. specification

I718H1140285-01

(A)

I718H1140286-01

“A”

I823H1140284-01

Code “A” I.D. specification

1

38.000 – 38.008 mm

(1.4961 – 1.4964 in)

2

38.008 – 38.016 mm

(1.4964 – 1.4967 in)

(A)

I718H1140289-01

“A”

I718H1140290-01

Manuals by Motomatrix / The Solution For Lost Motorcycle Coded Keys

email: info@motomatrix.co.uk / www.motomatrix.co.uk

Loading...

Loading...