1F-17 Engine Cooling System:

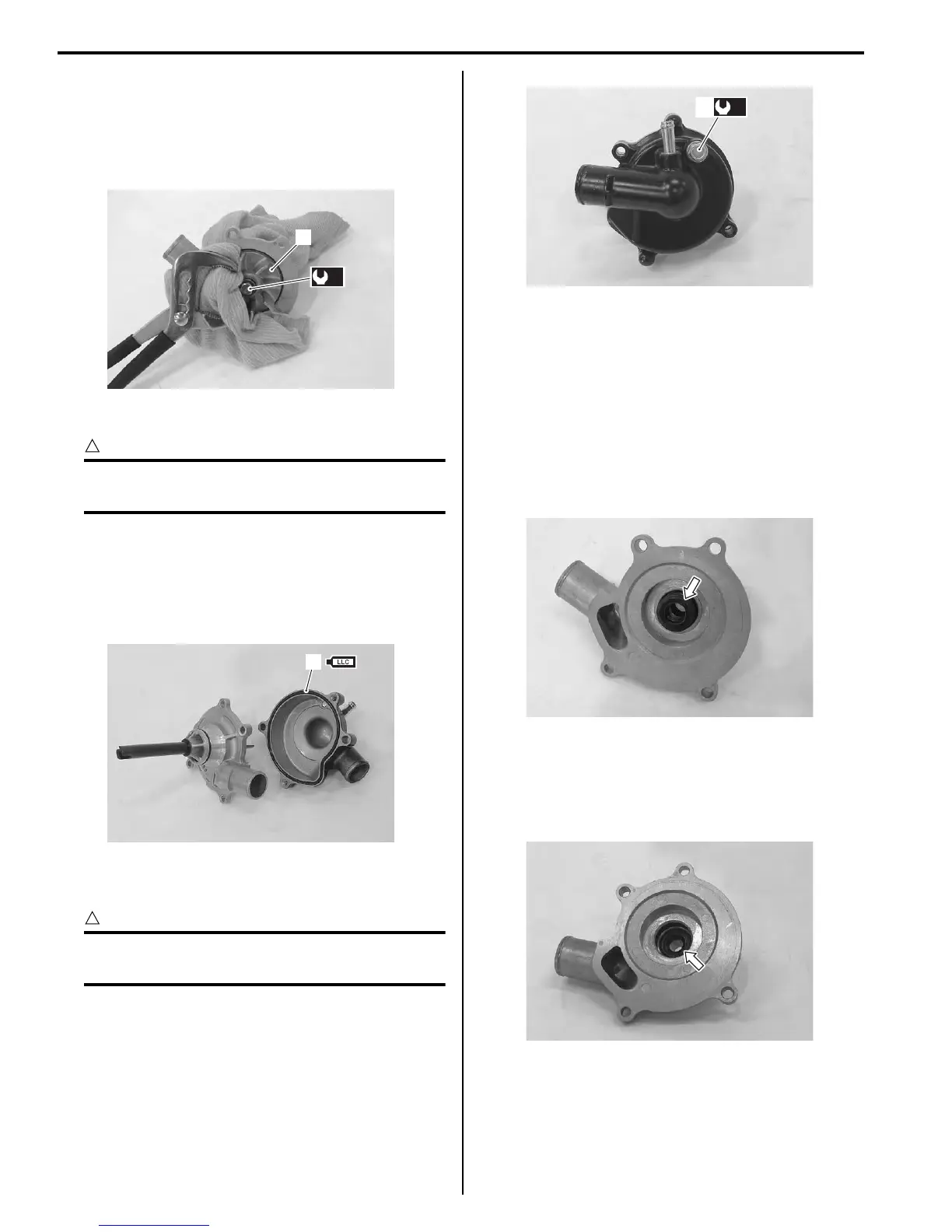

10) Hold the impeller with water pump pliers and tighten

the impeller securing bolt to the specified torque.

Tightening torque

Impeller securing bolt (a): 8 N·m (0.8 kgf-m, 6.0

lbf-ft)

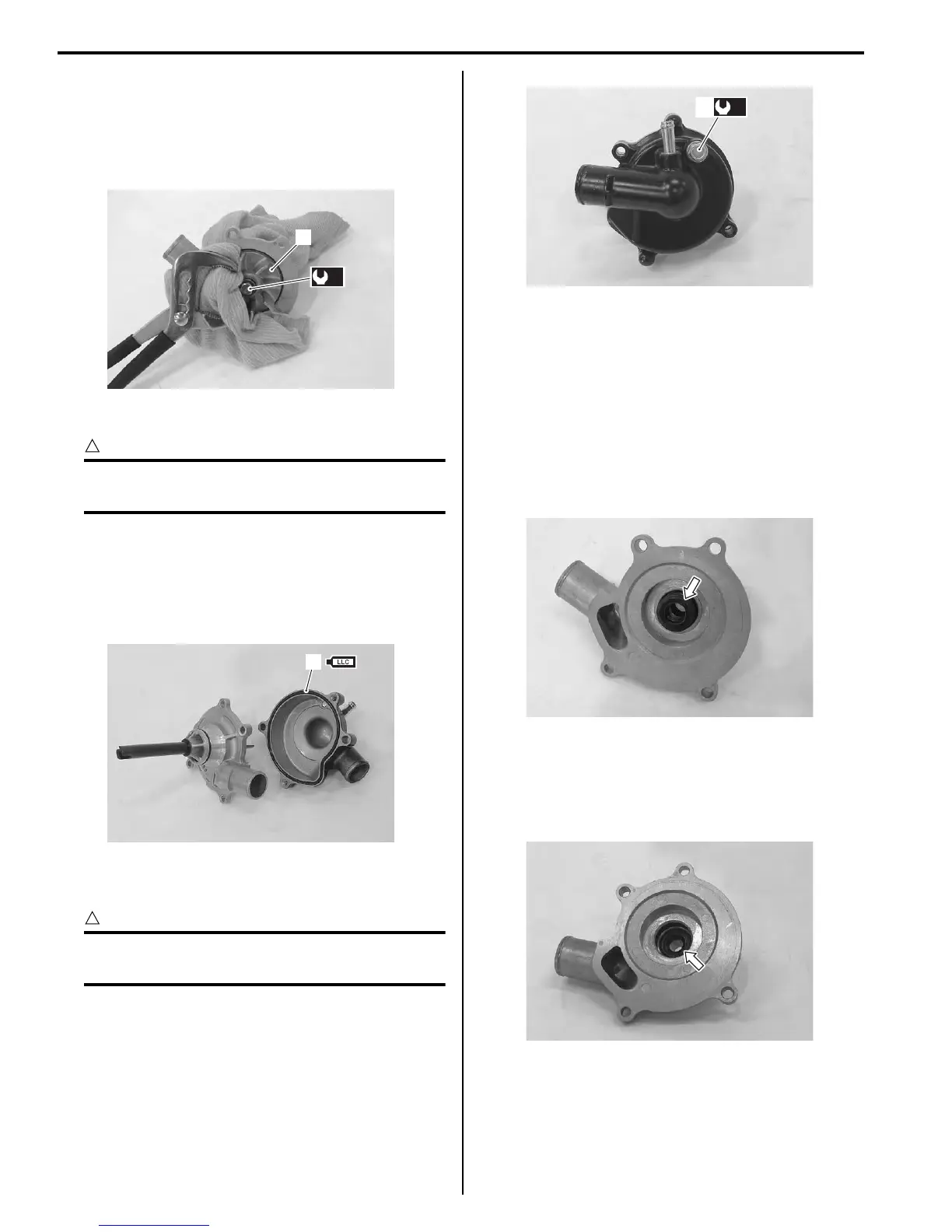

11) Install new O-ring (8) and apply engine coolant to it.

CAUTION

!

Use a new O-ring to prevent engine coolant

leakage.

12) Tighten the water pump case screws to the specified

torque.

Tightening torque

Water pump case screw: 6 N·m (0.6 kgf-m, 4.5

lbf-ft)

13) Tighten the water pump air bleeder bolt (9) to the

specified torque.

CAUTION

!

Use a new gasket washer to prevent engine

coolant leakage.

Tightening torque

Water pump air bleeder bolt (b): 13 N·m (1.3 kgf-

m, 9.5 lbf-ft)

Water Pump Related Parts Inspection

B947H11606019

Refer to “Water Pump Disassembly and Assembly”

(Page 1F-14).

Mechanical Seal

Visually inspect the mechanical seal for damage, with

particular attention given to the sealing face.

Replace the mechanical seal that shows indications of

leakage.

Oil Seal

Visually inspect the oil seal for damage, with particular

attention given to the lip.

Replace the oil seal that shows indications of leakage.

(a)

7

I947H1160043-02

8

I947H1160044-02

(b)

9

I947H1160045-01

I947H1160046-01

I947H1160047-01

Manuals by Motomatrix / The Solution For Lost Motorcycle Coded Keys

email: info@motomatrix.co.uk / www.motomatrix.co.uk

Loading...

Loading...