5C-13 Clutch:

Clutch Lifter Pin Inspection and Adjustment

B947H15306009

Refer to “Clutch Removal” (Page 5C-5) and “Clutch

Installation” (Page 5C-7).

NOTE

When inspection and adjusting the clutch

lifter pin, it is not necessary to install the

clutch onto the countershaft.

Inspect and adjust the clutch lifter pin in the following

procedures:

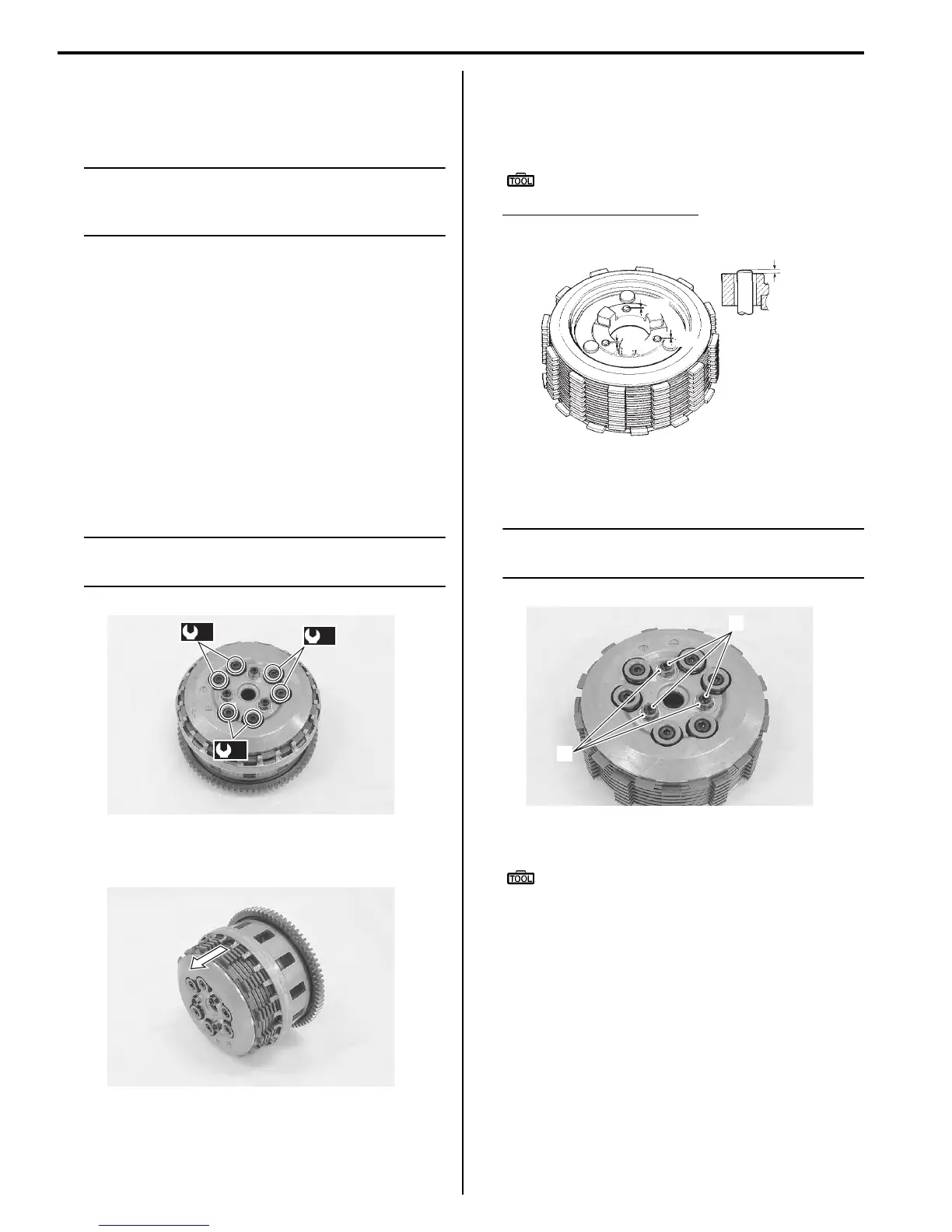

1) Assemble the following parts into the primary driven

gear assembly.

• Clutch sleeve hub

• Spring washer seat, spring washer

• Clutch drive plates, clutch driven plates

• Pressure plate

• Clutch springs, clutch springs set bolts

Tightening torque

Clutch spring set bolt (a): 10 N·m (1.0 kgf-m, 7.0

lbf-ft)

NOTE

Tighten the clutch spring set bolt little by

little and diagonally.

2) Remove the clutch assembly from the primary driven

gear assembly.

3) Inspect the height “A” of clutch lifter pin at three

positions using the thickness gauge. If the

measurement is out of the specification, adjust the

height “A” as shown in the figure.

Special tool

: 09900–20803 (Thickness gauge)

Clutch lifter pin height “A”

Standard: 0.2 – 0.4 mm (0.008 – 0.016 in)

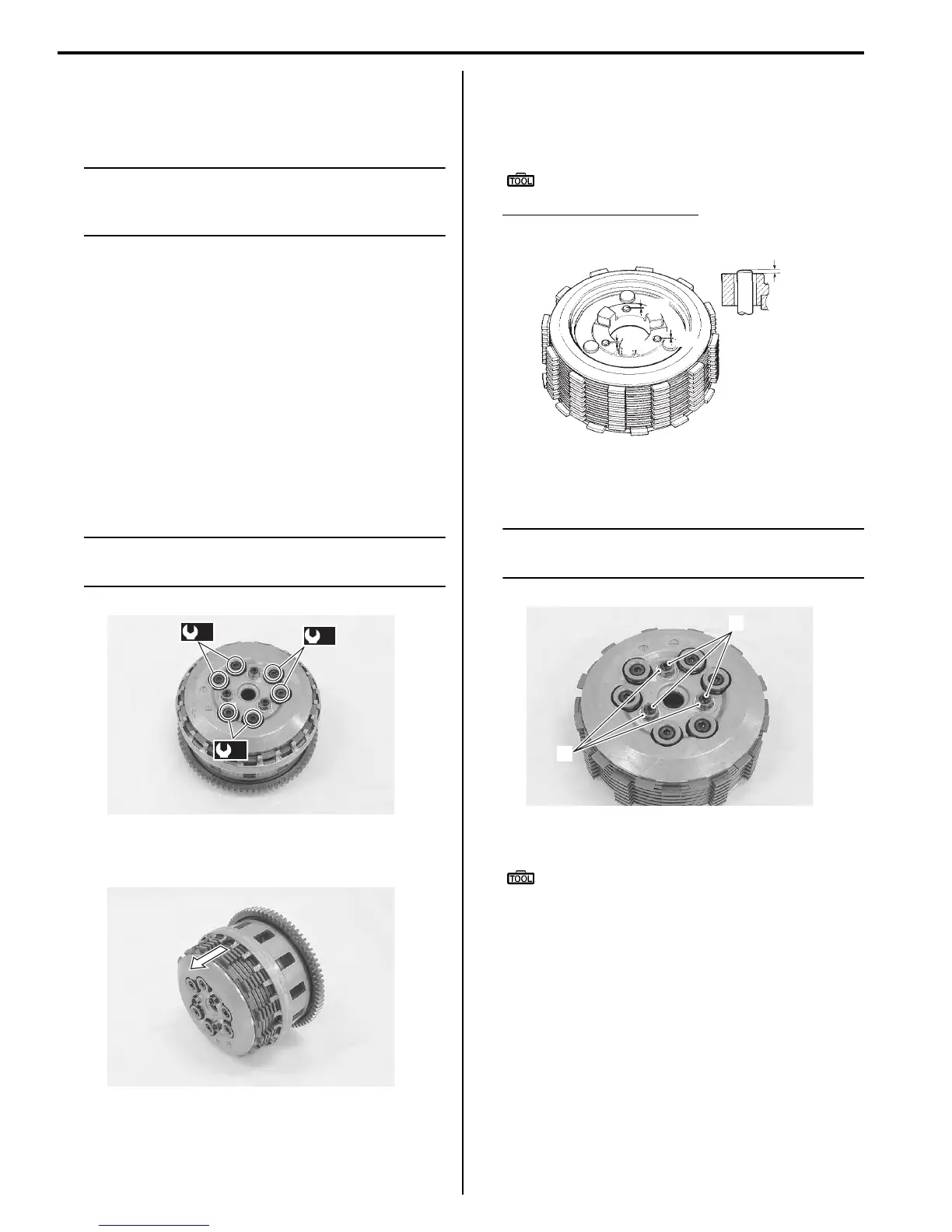

4) Loosen the lock-nuts (1) and turn out the clutch lifter

pin (2).

NOTE

Each clutch lifter pin height should be as

closely as possible.

5) Set the thickness gauge to 0.3 mm (0.012 in).

Special tool

(A): 09900–20803 (Thickness gauge)

6) Place a proper flat plate on the thickness gauges

and hold them by hand.

7) Slowly turn in the clutch lifter pin (2) until resistance

is felt.

(a)

(a)

(a)

I947H1530038-01

I947H1530039-01

“A”

“A”

“A”

“A”

I837H1530044-01

1

2

I947H1530040-01

Manuals by Motomatrix / The Solution For Lost Motorcycle Coded Keys

email: info@motomatrix.co.uk / www.motomatrix.co.uk

Loading...

Loading...