15 February 2006 SERVICE PROGRAM MODE TABLES

5-35

Service

Tables

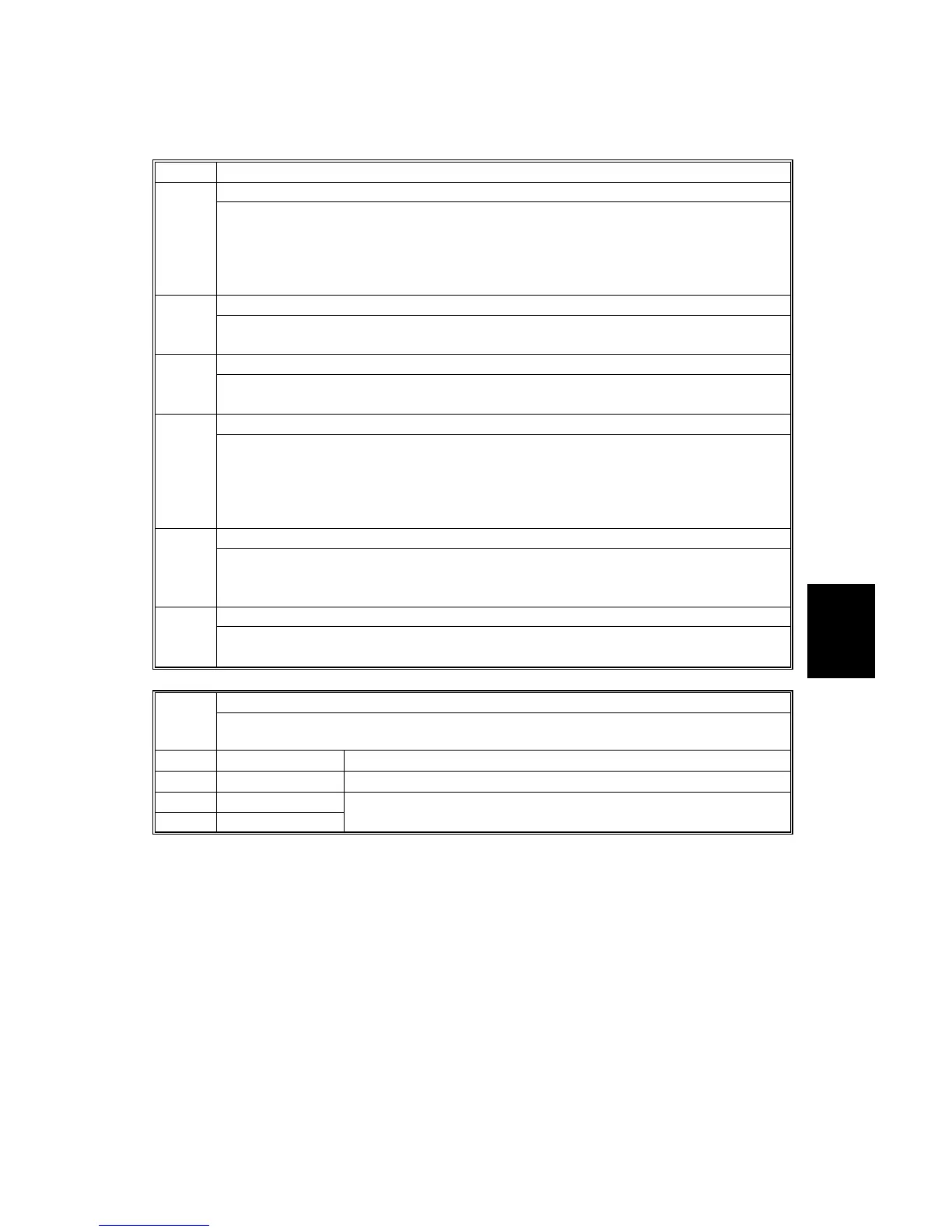

SP2xxx Drum

2001* Charge Roller Bias Adjustment

001 Applied Voltage for Image Processing

Adjusts the voltage applied to the grid plate during copying when auto process

control is off.

[–600~–1300/ 10 V]

After replacing the charge corona wire or the drum, reset to the factory default

setting.

002 ID Sensor Pattern: Adjustment of Applied Voltage

Adjusts the voltage applied to the grid plate when the ID sensor pattern is created.

[–600~–1300/10 V]

003 Setting for Total Bias Current

Adjusts the total current applied to the charge corona wire. DFU

[–900~–1500/10 µA]

004 Setting for Total Bias Current of Grid

Adjusts the voltage applied to the grid plate during copying when auto process

control is on.

[–600~–1300/10 µA]

This voltage changes every time auto process control starts up (every time the

machine is switched on).

005 Total Bias Grid Current: OHP Total

Adjusts the voltage applied to the grid plate when OHP mode is selected.

[–600~–1300/10 V]

Use this if there is a copy quality problem when making OHP’s.

006 Total Bias Current: Photo Mode Total

Adjusts the voltage applied to the grid plate when Photo mode is selected. DFU

[–1400~ –2800/10 µA]

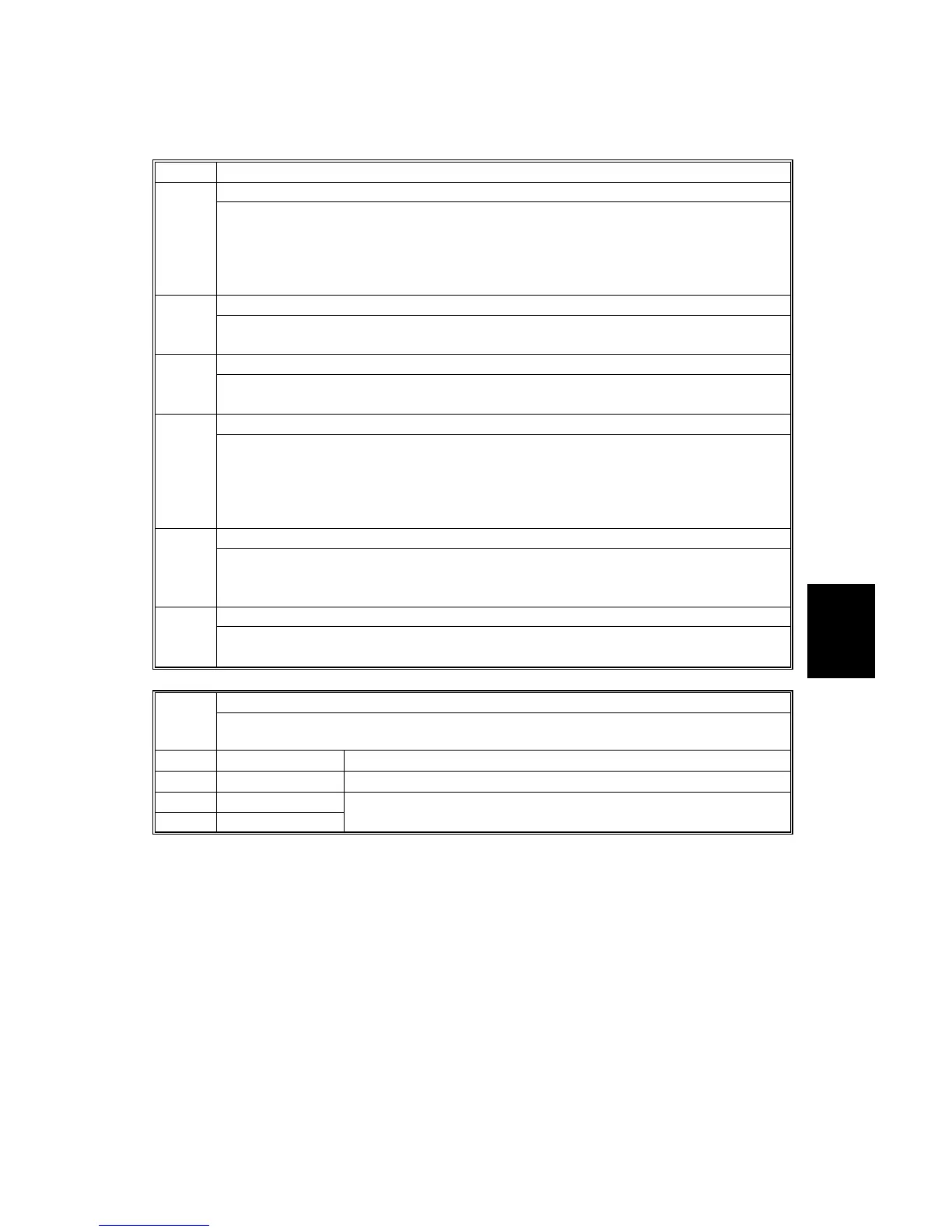

2101* Printing Erase Margin

These settings adjust the erase margin for the leading, trailing, left, and right

edges.

001 Leading Edge

[0.0~9.0/0.1 mm], Specification: 3±2 mm

002 Trailing Edge

[0.0~9.0/0.1 mm], Specification: 3±2 mm

003 Left Edge

004 Right Edge

[0.0~9.0/0.1 mm], Specification: 2±1.5 mm

Loading...

Loading...