February, 2008

4-221

WorkCentre 5225, 5230

ADJ 7.1.2

Repairs and Adjustments

Launch Version

ADJ 7.1.2 HCF Side Edge Registration

Purpose

The purpose of this adjustment is to properly align the ROS image to the paper / media, for the

High Capacity Feeder, (Tray 6), print and copy modes. This adjustment can only be accom

-

plished after the IOT Image Registration, and the IIT Lead Edge/Side Edge Registration.

Check

1. Access Diagnostic Routines.

a. Enter UI Diagnostics (UI Diagnostic Mode).

2. Select Print Test Pattern and enter test pattern number 58.

3. Under Paper Supply select Tray 6 (HCF) and select Save.

4. Press the Start button.

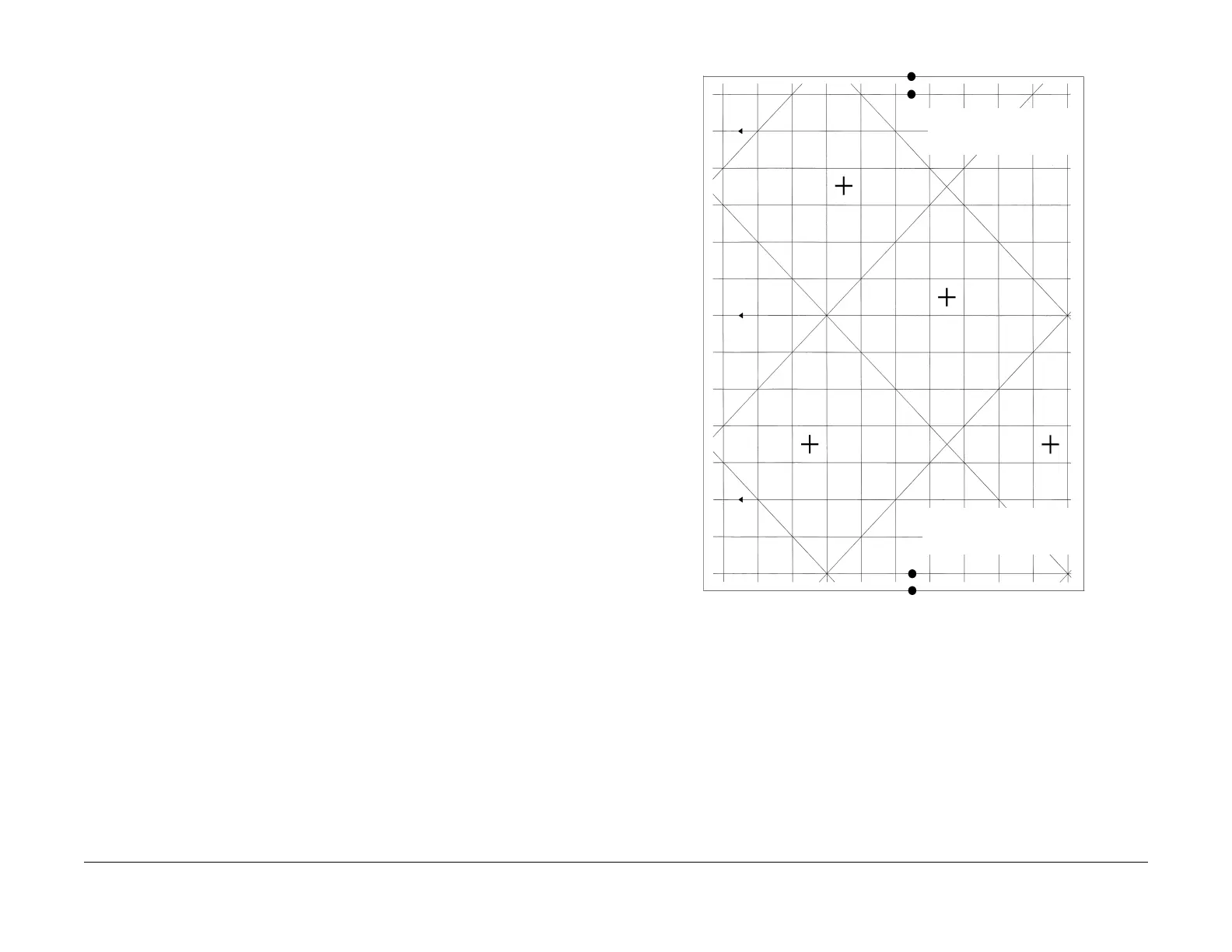

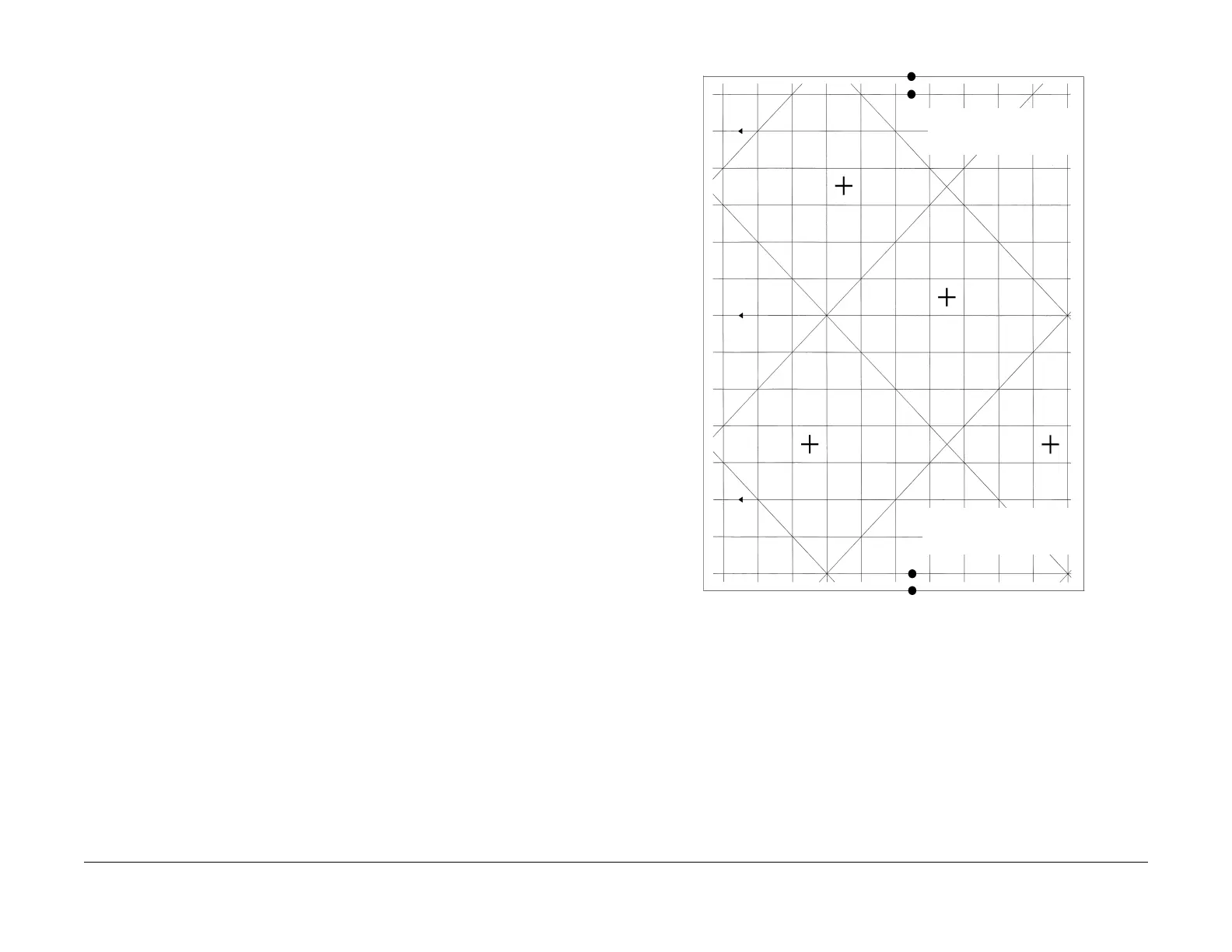

5. Measure the distance from the last horizontal line to the edge of the paper on the inboard

end and the outboard end of the page. The measurement should be 10mm =/- 0.5mm.

(Figure 1)

6. If the measurement is not within specifications, perform the adjustment. Do not perform

side 2 adjustments until side 1 adjustments are correct.

Figure 1 Test Pattern #58 Measurement points

CHECKING SIDE 2 PLAIN PAPER FROM TRAY 6

1. To check for side 1 to side 2 side edge registration place the side 1 test pattern on the

document glass and use this test pattern to create a duplex copy from tray 6.

NOTE: Before making side 2, place a small piece of paper, with the words “side 2” written

on it, face down under the test pattern.

2. Hold the sheet in front of a strong light source to pass light through the paper to see a side

1 and side 2 comparison. Adjust side 1 or side 2 as necessary.

Measurement points Side

Edge 10mm =/- 0.5mm

Measurement points Side

Edge 10mm =/- 0.5mm

Loading...

Loading...