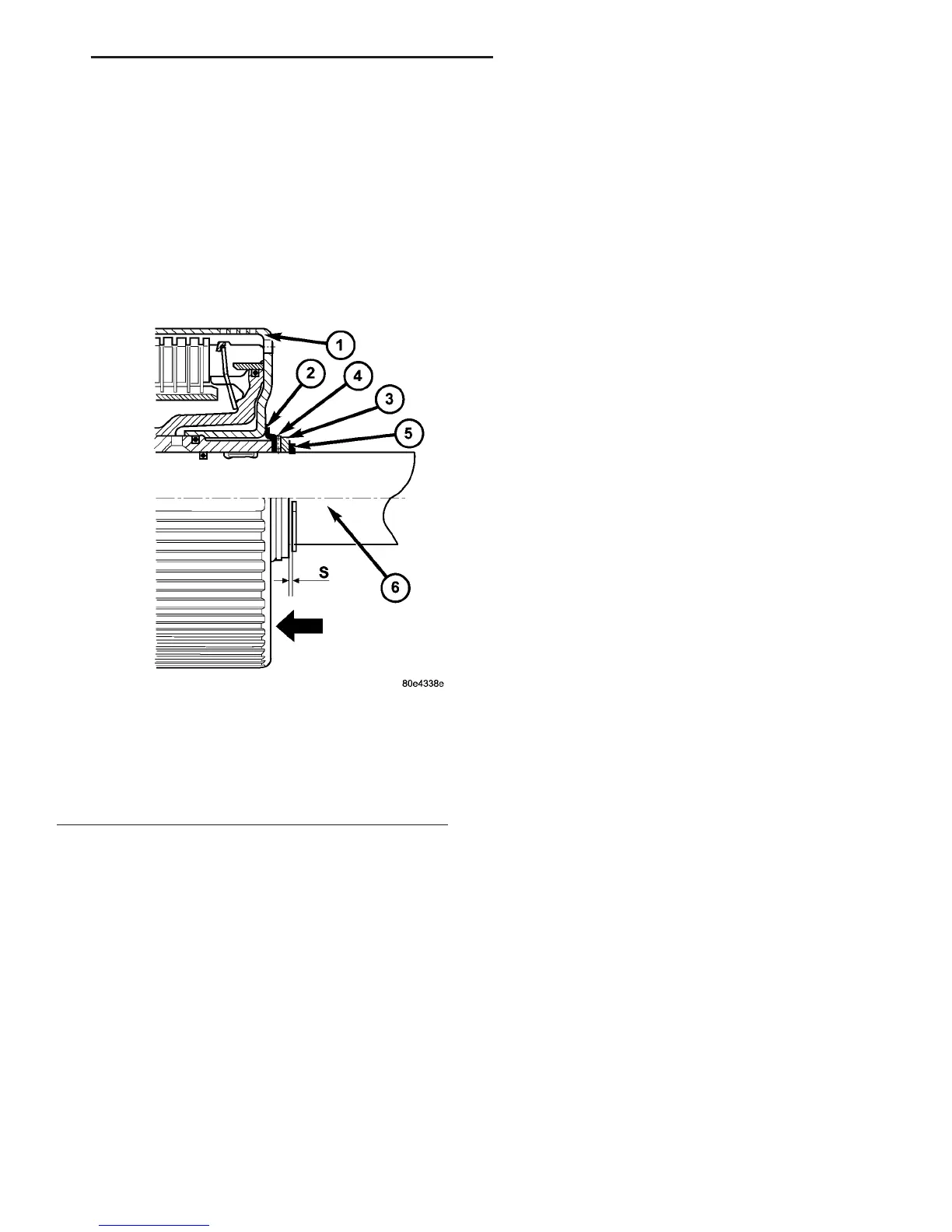

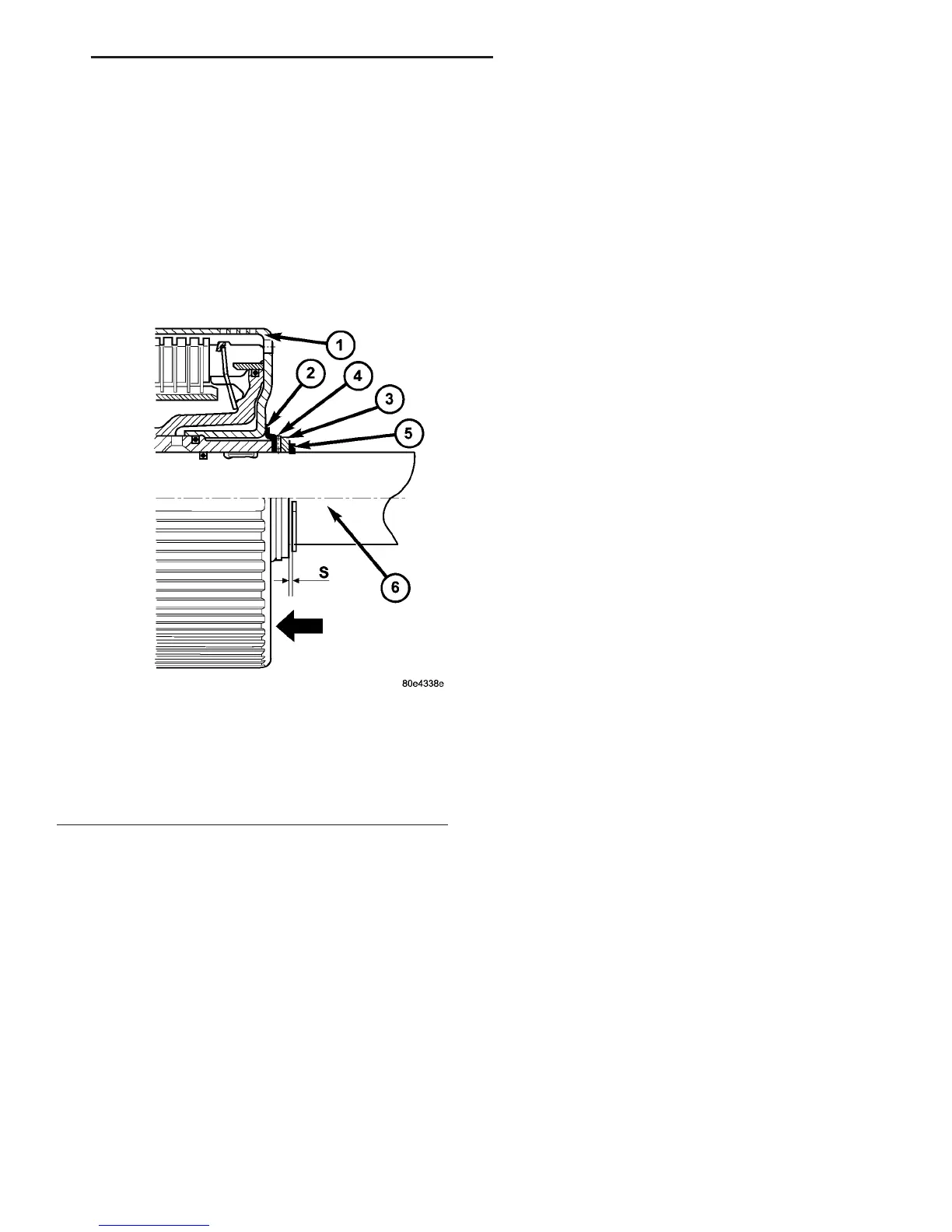

(8) Inspect axial play (Fig. 203) between shim (10)

and retaining ring (11). Check axial play 9S9 between

shim (10) and retaining ring (1) using a feeler gauge.

Clearance should be 0.15-0.6 mm (0.006-0.024 in.).

Shims are available in thicknesses of 3.0 mm (0.118

in.), 3.4 mm (0.134 in.), and 3.7 mm (0.146 in.).

Adjust as necessary

NOTE: During the test, apply a contact force by

hand to K3 in the direction of the arrow.

SHIFT MECHANISM

DESCRIPTION

The automatic transmission is operated with the

help of a shift lever assembly (SLA) located in the

center console. There are four positions to which the

selection lever can be shifted: P, R, N, D. In addition,

the selector lever can be moved sideways (+/-) in posi-

tion 9D9 to adjust the shift range.

All selector lever positions, as well as selected shift

ranges in position 9D9, are identified by the SLA. The

information is then sent to the transmission control

module (TCM) via a hardwire connection. At the

same time, the selector lever positions 9P9, 9R9, 9N9

and 9D9 are transmitted by a shift cable to the selec-

tor shaft in the transmission.

The SLA is comprised of the following functions:

• Key lock: Depending on the selector lever posi-

tion, the ignition lock is locked/unlocked, i.e., the

ignition key can be removed only if the selector lever

is in position 9P9. A park lock cable is used to perform

this function.

• Park lock: The selector lever is not released

from postion 9P9 until the brake pedal has been

applied and the ignition key is in driving position.

Shift lock is controlled by the brake light switch in

conjunction with a locking solenoid in the SLA. As

soon as the brake pedal is applied firmly, the locking

solenoid is retracted to unlock the selector lever. If

the selector lever cannot be moved out of position 9P9

due to a malfunction, the shift lock function can be

overriden (see operator’s manual).

• Reverse inhibitor: As soon as the vehicle

speed exceeds approx. 4 mph, it is no longer possible

to move the selector lever from position 9N9 to posi-

tion 9R9.

OPERATION

With the selector lever in position 9D9, the trans-

mission control module (TCM) automatically shifts

the gears that are best-suited to the current operat-

ing situation. This means that shifting of gears is

continuously adjusted to current driving and operat-

ing conditions in line with the selected shift range

and the accelerator pedal position. Starting off is

always performed in 1st gear.

The selector lever positions are determined by the

slider position of a potentiometer in the shift lever

assembly (SLA). The shift pattern diagram (position

display) and the program selector are illuminated by

the LEDs.

The current selector lever position or, if the shift

range has been limited, the current shift range is

indicated in the LCD display in the instrument clus-

ter.

The permissible shifter positions and transmission

operating ranges are:

• P = Parking lock and engine starting.

• R = Reverse.

• N = Neutral and engine starting (no power is

transmitted to the axles).

• D = The shift range includes all forward gears.

• 4= Shift range is limited to gears 1 to 4.

• 3= Shift range is limited to gears 1 to 3.

• 2= Shift range is limited to gears 1 to 2.

• 1= Shift range is limited to the 1st gear.

The shift range can be adjusted to the current

operating conditions by tipping the selector lever to

the left-hand side (9-9) or the right-hand side (9+9)

when in position 9D9. If the shift range is limited, the

display in the instrument cluster indicates the

selected shift range and not the currently engaged

gear.

Fig. 203 Check Center and Rear Planetary End-Play

1 - DRIVING CLUTCH K3

2 - THRUST WASHER

3 - SHIM

4 - AXIAL NEEDLE BEARING

5 - RETAINING RING

6 - OUTPUT SHAFT WITH CENTER PLANETARY CARRIER

VA AUTOMATIC TRANSMISSION - NAG1 21 - 133

PLANETARY GEARTRAIN (Continued)

Loading...

Loading...