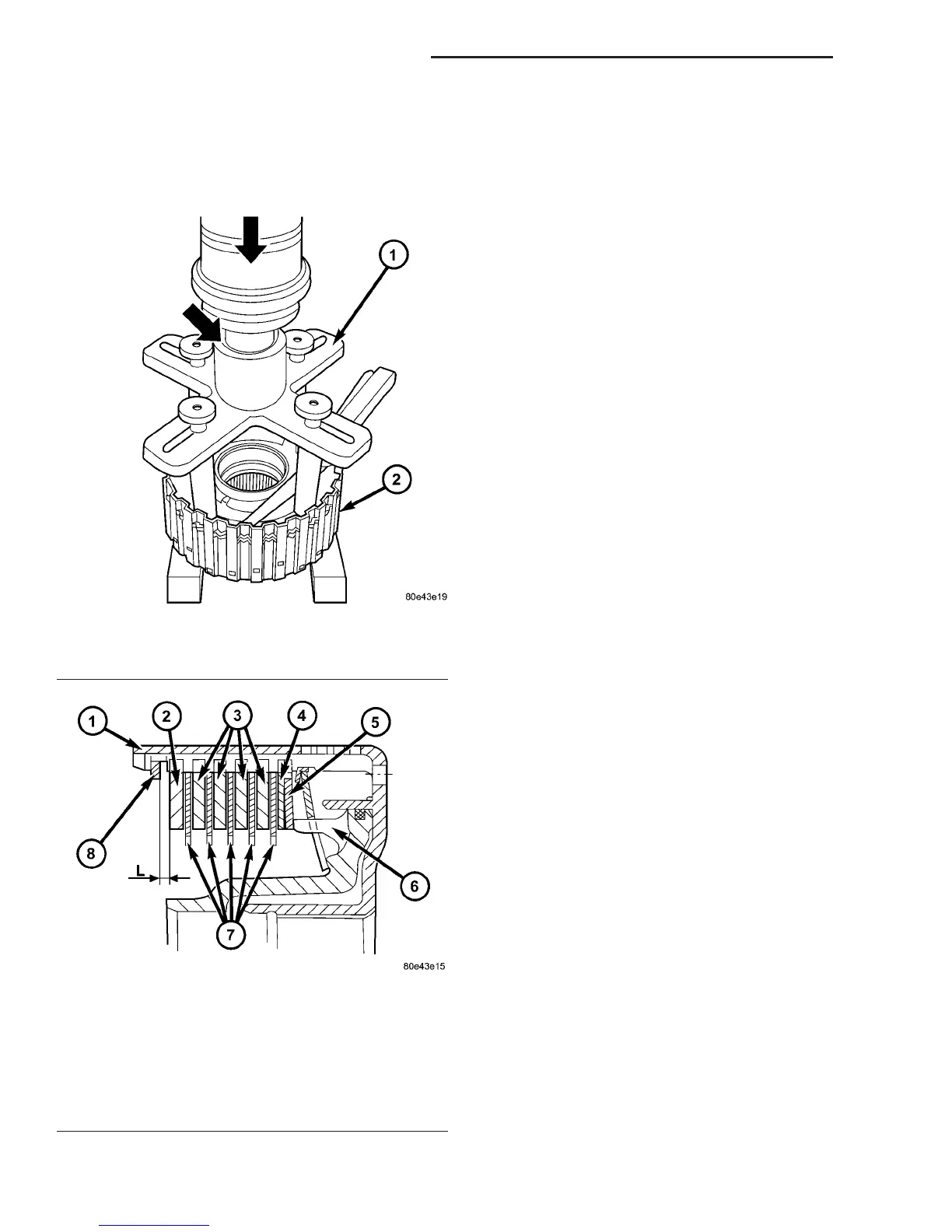

(f) Adjust with snap-ring (8), if necessary. Snap-

rings are available in thicknesses of 2.0 mm (0.079

in.), 2.3 mm (0.091 in.), 2.6 mm (0.102 in.), 2.9 mm

(0.114 in.), 3.2 mm (0.126 in.), and 3.5 mm (0.138

in.).

ELECTROHYDRAULIC UNIT

DESCRIPTION

The electrohydraulic control unit comprises the

shift plate made from light alloy for the hydraulic

control and an electrical control unit. The electrical

control unit comprises of a supporting body made of

plastic, into which the electrical components are

assembled. The supporting body is mounted on the

shift plate and screwed to it.

Strip conductors inserted into the supporting body

make the connection between the electrical compo-

nents and a plug connector. The connection to the

wiring harness on the vehicle and the transmission

control module (TCM) is produced via this 13-pin

plug connector with a bayonet lock.

ELECTRICAL CONTROL UNIT

The electric valve control unit (7) (Fig. 88) consists

of a plastic shell which houses the RPM sensors

(1,12), regulating solenoid valves (3, 4), solenoid

valves (5, 6, 10), the TCC solenoid valve (11), the

park/neutral contact (9), and the transmission oil

temperature sensor (8). Conductor tracks integrated

into the shell connect the electric components to a

plug connection (2). This 13-pin plug connection (2)

establishes the connection to the vehicle-side cable

harness and to the transmission control module

(TCM). With the exception of the solenoid valves, all

other electric components are fixed to the conductor

tracks.

HYDRAULIC CONTROL UNIT

Working Pressure (Operating Pressure) (p-A)

The working pressure provides the pressure supply

to the hydraulic control and the transmission shift

elements. It is the highest hydraulic pressure in the

entire hydraulic system. The working pressure is reg-

ulated at the working pressure regulating valve in

relation to the load and gear. All other pressures

required for the transmission control are derived

from the working pressure.

Lubrication Pressure (p-Sm)

At the working pressure regulating valve surplus

oil is diverted to the lubrication pressure regulating

valve, from where it is used in regulated amounts to

lubricate and cool the mechanical transmission com-

ponents and the torque converter. Furthermore, the

lubrication pressure (p-Sm) is also used to limit the

pressure in the torque converter.

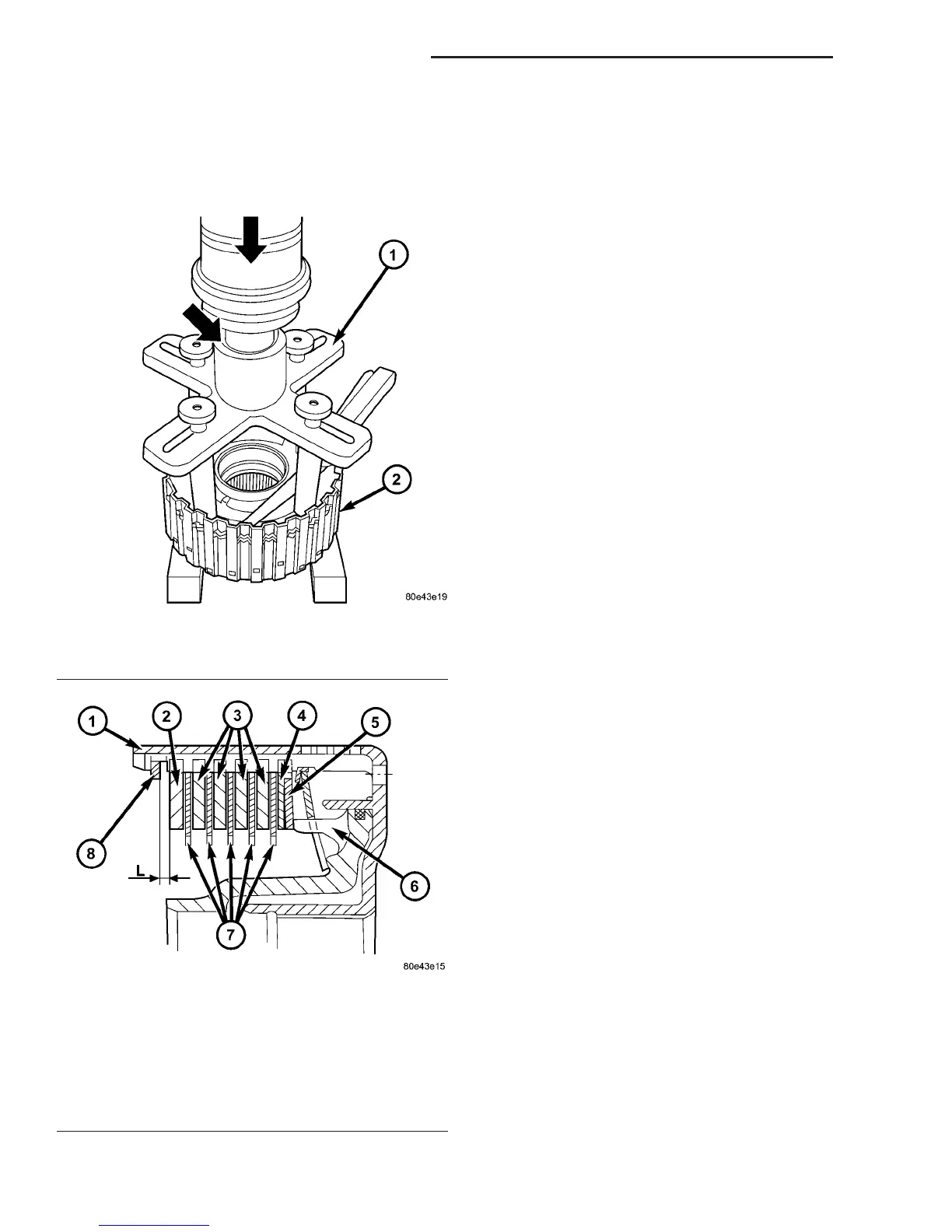

Fig. 86 Measure K3 Clutch Clearance

1 - PRESSING TOOL 8901

2 - OUTER DISC CARRIER

Fig. 87 Driving Clutch K3 Stack-up

1 - OUTER DISC CARRIER

2 - OUTER MULTIPLE DISC - 4.0 MM (0.158 IN.)

3 - OUTER MULTIPLE DISC - 2.8 MM (0.110 IN.)

4 - OUTER MULTIPLE DISC - 1.8 MM (0.079 IN.)

5 - DISC SPRING

6 - PISTON

7 - FRICTION DISCS - 2.1 MM (0.083 IN.)

8 - SNAP-RING

21 - 82 AUTOMATIC TRANSMISSION - NAG1 VA

DRIVING CLUTCH K3 (Continued)

Loading...

Loading...