PARTS & LUBRICANT

RECOMMENDATION

STANDARD PROCEDURE - PARTS &

LUBRICANT RECOMMENDATIONS

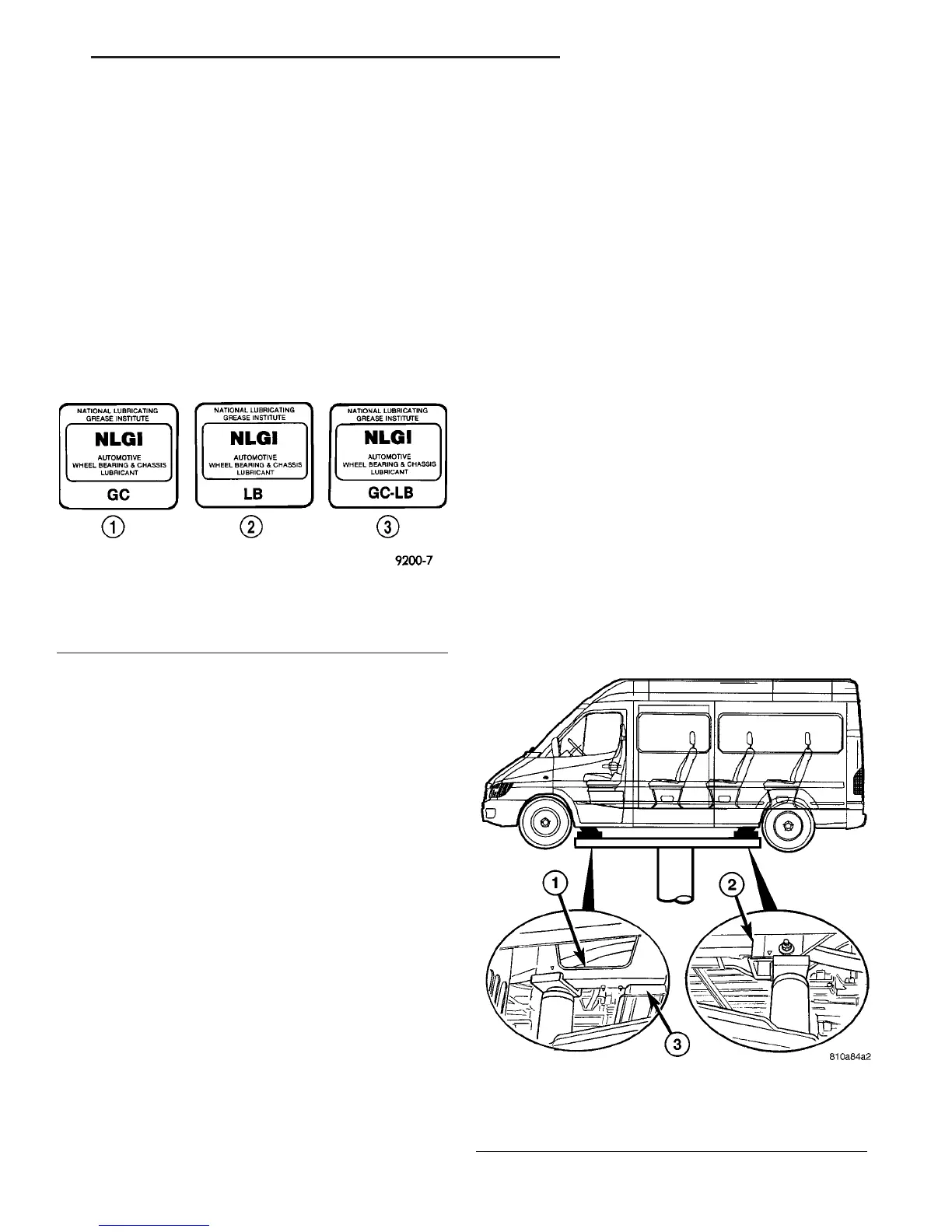

Lubricating grease is rated for quality and usage

by the NLGI. All approved products have the NLGI

symbol (Fig. 1) on the label. At the bottom NLGI

symbol is the usage and quality identification letters.

Wheel bearing lubricant is identified by the letter

“G”. Chassis lubricant is identified by the latter “L”.

The letter following the usage letter indicates the

quality of the lubricant. The following symbols indi-

cate the highest quality.

When service is required, DaimlerChrysler Corpo-

ration recommends that only Mopart brand parts,

lubricants and chemicals be used. Mopar provides

the best engineered products for servicing

DaimlerChrysler Corporation vehicles.

HOISTING

STANDARD PROCEDURE - HOISTING

Refer to the Owner’s Manual for emergency vehicle

lifting procedures.

WARNING: THE HOISTING AND JACK LIFTING

POINTS PROVIDED ARE FOR A COMPLETE VEHI-

CLE. WHEN A CHASSIS OR DRIVETRAIN COMPO-

NENT IS REMOVED FROM A VEHICLE, THE

CENTER OF GRAVITY IS ALTERED MAKING SOME

HOISTING CONDITIONS UNSTABLE. PROPERLY

SUPPORT OR SECURE VEHICLE TO HOISTING

DEVICE WHEN THESE CONDITIONS EXIST.

FLOOR JACK

When properly positioned, a floor jack can be used

to lift a vehicle. Support the vehicle in the raised

position with jack stands at the front and rear ends

of the frame rails.

CAUTION: Do not lift vehicle with a floor jack posi-

tioned under:

• An axle tube.

• A body side sill.

• A steering linkage component.

• A drive shaft.

• The engine or transmission oil pan.

• The fuel tank.

• A front suspension arm.

HOIST

A vehicle can be lifted with:

• A single-post, frame-contact hoist.

• A twin-post, chassis hoist.

• A ramp-type, drive-on hoist.

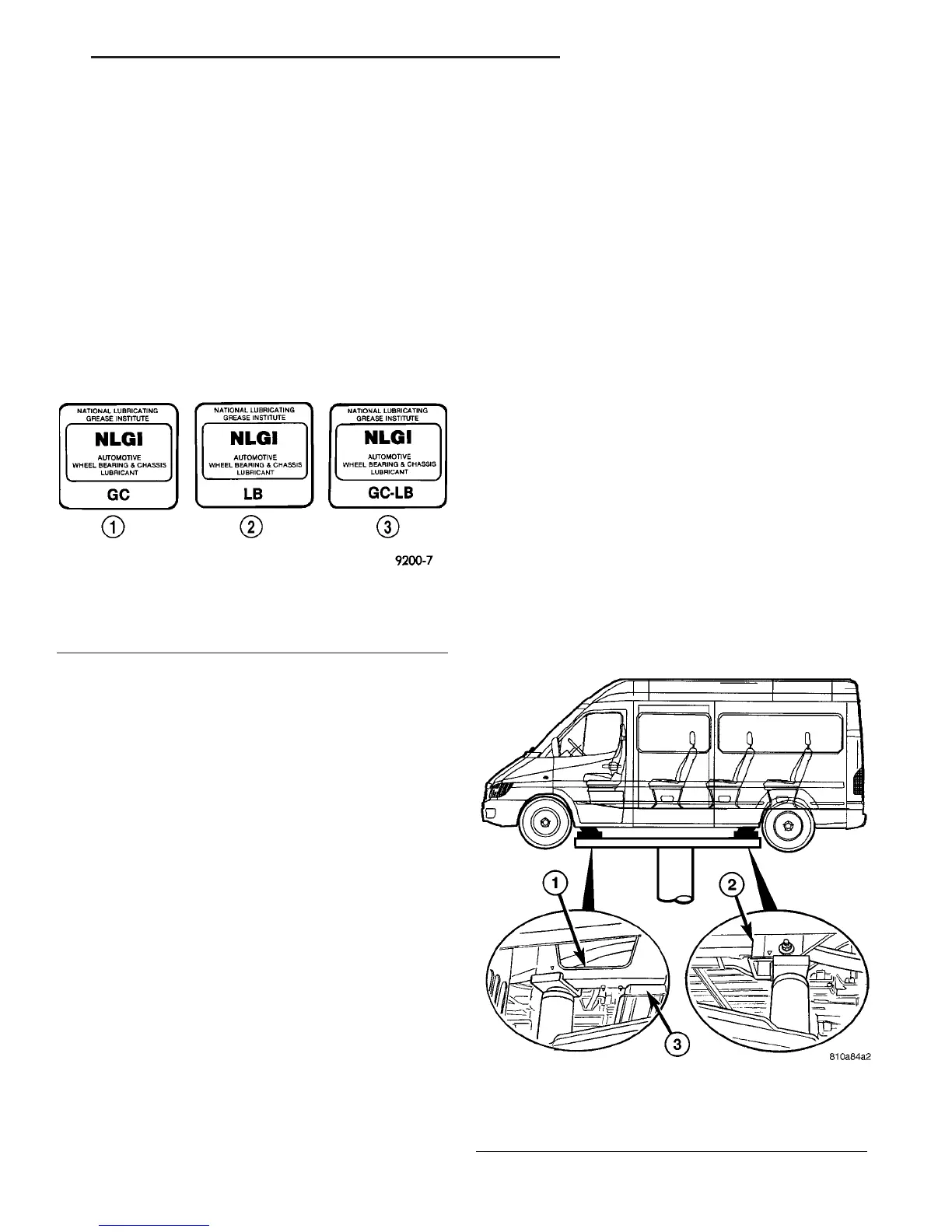

NOTE: When a frame-contact type hoist is used,

verify that the lifting pads are positioned properly.

The forward lifting pads should be positioned

against the forward flange of the transmission

crossmember brackets at the bottom of the frame

rail. The real lifting pads should be wedged

between the forward flange of the leaf spring

bracket and the frame rail. Safety stands should be

placed under the frame rails at the front and rear

ends (Fig. 2).

Fig. 1 NLGI Symbol

1 - WHEEL BEARINGS

2 - CHASSIS LUBRICATION

3 - CHASSIS AND WHEEL BEARINGS

Fig. 2 HOIST LOCATIONS

1 - TRANSMISSION CROSSMEMBER SUPPORT

2 - REAR LEAF SPRING MOUNT - FRONT

3 - TRANSMISSION CROSSMEMBER

VA LUBRICATION & MAINTENANCE 0 - 5

Loading...

Loading...