INSTALLATION

(1) Select a wire from the terminal repair kit that

best matches the color and gage of the wire being

repaired.

(2) Cut the repair wire to the proper length and

remove one–half (1/2) inch of insulation.

(3) Splice the repair wire to the wire harness (see

wire splicing procedure).

(4) Insert the repaired wire into the connector.

(5) Install the connector locking wedge, if required,

and reconnect the connector to its mating half/compo-

nent.

(6) Re-tape the wire harness starting at 1–1/2

inches behind the connector and 2 inches past the

repair.

(7) Connect battery and test all affected systems.

WIRE

STANDARD PROCEDURE - WIRE SPLICING

When splicing a wire, it is important that the cor-

rect gage be used as shown in the wiring diagrams.

(1) Remove one-half (1/2) inch of insulation from

each wire that needs to be spliced.

(2) Place a piece of adhesive lined heat shrink tub-

ing on one side of the wire. Make sure the tubing will

be long enough to cover and seal the entire repair

area.

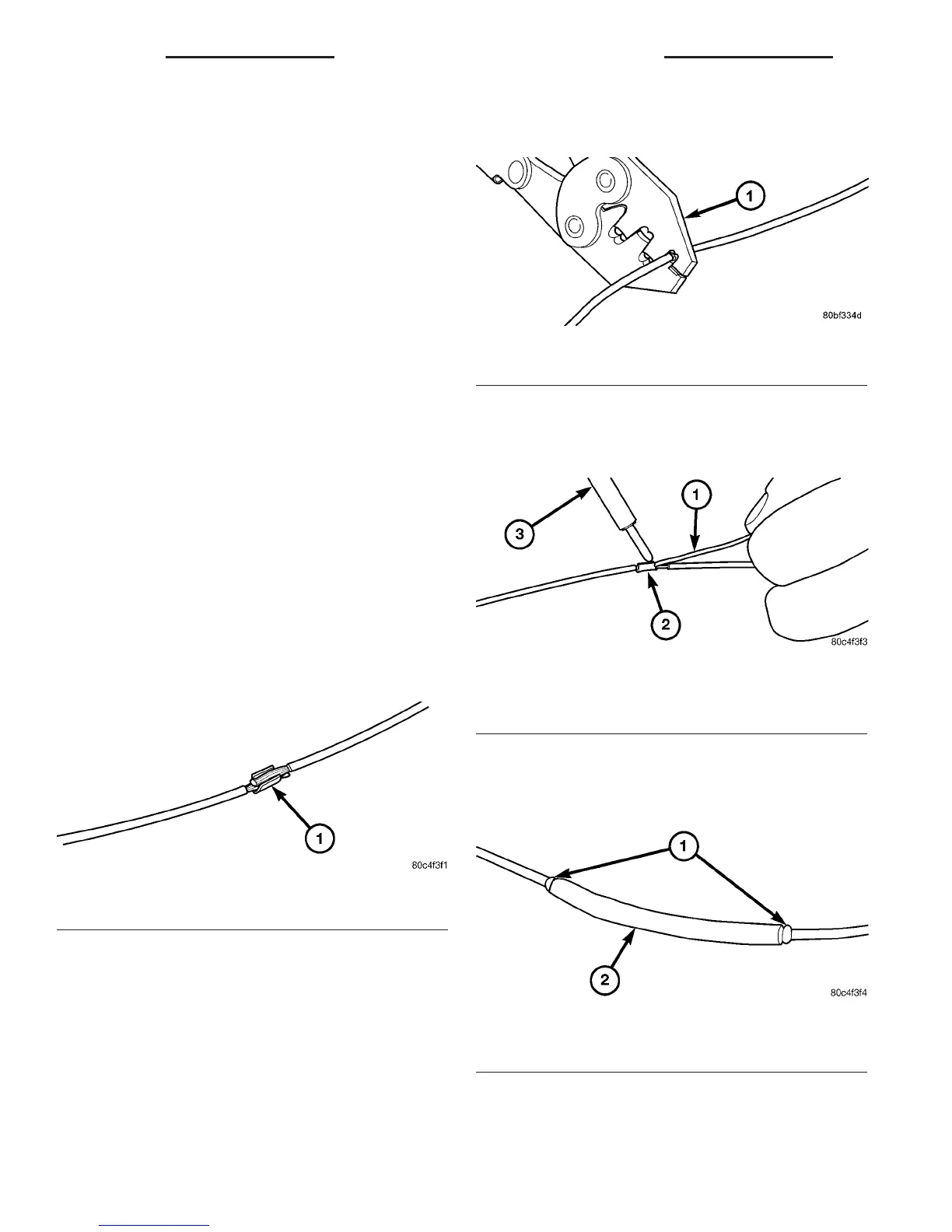

(3) Place the strands of wire overlapping each

other inside of the splice clip (Fig. 11).

(4) Using crimping tool, Mopar p/n 05019912AA,

crimp the splice clip and wires together (Fig. 12).

(5) Solder the connection together using rosin core

type solder only (Fig. 13).

CAUTION: DO NOT USE ACID CORE SOLDER.

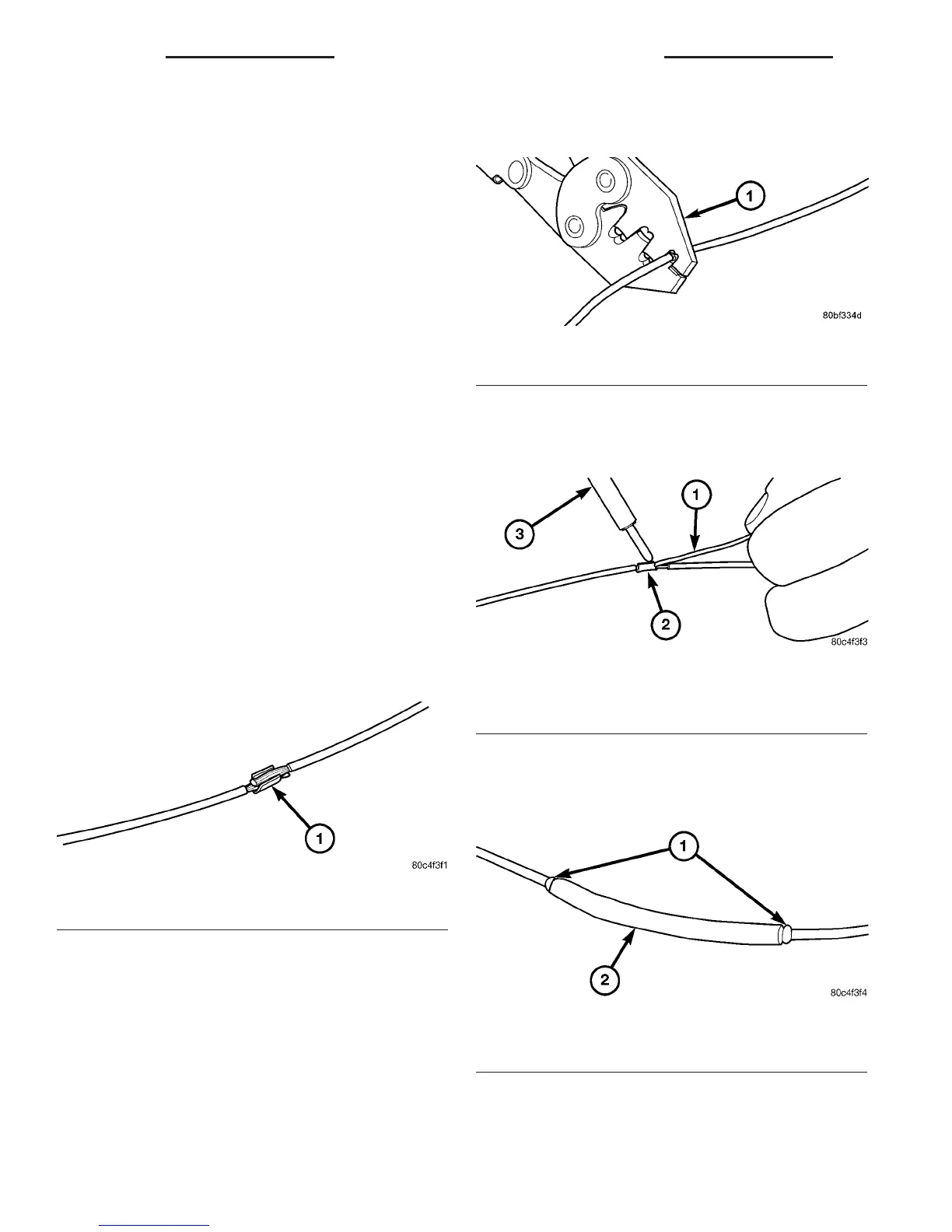

(6) Center the heat shrink tubing over the joint

and heat using a heat gun. Heat the joint until the

tubing is tightly sealed and sealant comes out of both

ends of the tubing (Fig. 14).

Fig. 11 1 SPLICE BAND

1 - SPLICE BAND

Fig. 12 2 CRIMPING TOOL

1 - CRIMPING TOOL

Fig. 13 3 SOLDER SPLICE

1 - SOLDER

2 - SPLICE BAND

3 - SOLDERING IRON

Fig. 14 4 HEAT SHRINK TUBE

1 - SEALANT

2 - HEAT SHRINK TUBE

8W - 01 - 10 8W-01 WIRING DIAGRAM INFORMATION VA

TERMINAL (Continued)

Loading...

Loading...