The compressor clutch engagement is controlled by

several components:

• A/C switch on the A/C-heater control panel

• Evaporator temperature sensor

• A/C pressure transducer

• Air temperature sensor

• CAN bus messages

The compressor clutch is de-energized under any of

the following conditions:

• Blocked compressor (thermal fuse in the pulley)

• Low pressure in the system

• Low evaporator temperature

• Hard acceleration (WOT)

• High coolant temperatures

STANDARD PROCEDURE

STANDARD PROCEDURE - COMPRESSOR

CLUTCH AIR GAP

If a new clutch plate and/or clutch pulley are being

used, the air gap between the clutch plate and clutch

pulley must be checked using the following proce-

dure:

(1) Using feeler gauges, measure the air gap

between the clutch plate and the clutch pulley fric-

tion surfaces.

(2) If the air gap is not between 0.5 and 0.9 mm

(0.020 and 0.035 in.), add or subtract shims until the

desired air gap is obtained.

NOTE: The shims may compress after tightening

the compressor shaft bolt. Check the air gap in four

or more places on the clutch plate to verify that the

air gap is still correct. Spin the clutch pulley before

making the final air gap check.

STANDARD PROCEDURE - COMPRESSOR

CLUTCH BREAK-IN

After a new compressor clutch has been installed,

cycle the compressor clutch approximately twenty

times (five seconds on, then five seconds off). During

this procedure, set the heater-A/C control in the

Recirculation Mode, the A/C button in the on posi-

tion, the blower motor switch in the highest speed

position, and the engine speed at 1500 to 2000 rpm.

This procedure (burnishing) will seat the opposing

friction surfaces and provide a higher compressor

clutch torque capability.

REMOVAL

The refrigerant system can remain fully-charged

during compressor clutch, pulley, or coil replacement.

The compressor clutch can be serviced in the vehicle.

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the serpentine drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

(3) Disconnect the engine wire harness connector

for the compressor clutch coil from the clutch coil

wire harness connector on the top of the compressor.

(4) Disengage the retainer on the engine wire har-

ness compressor clutch coil lead from the bracket on

the top of the compressor.

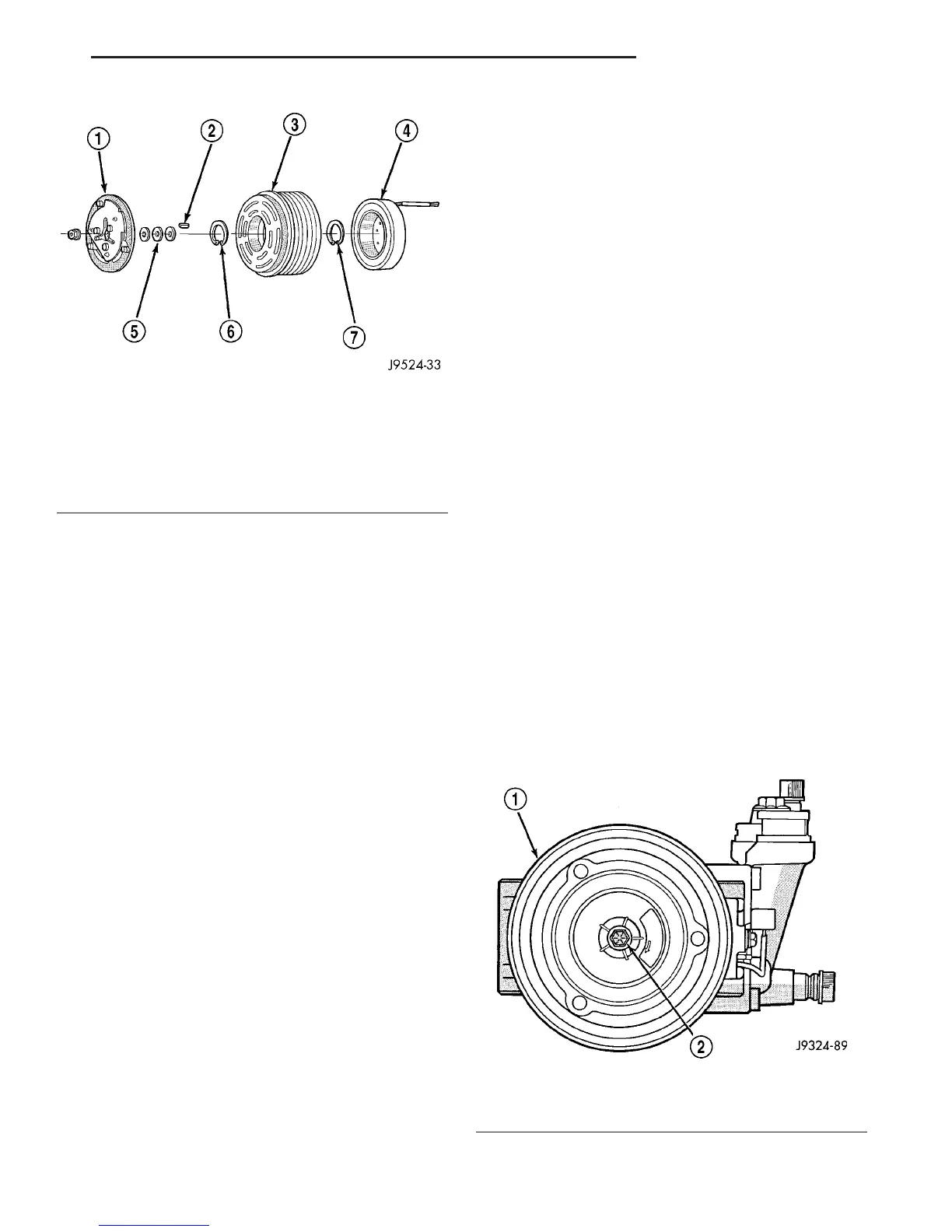

(5) Remove the bolt that secures the compressor

clutch to the compressor shaft (Fig. 2). If necessary, a

band-type oil filter wrench or strap wrench can be

placed around the clutch plate to aid in bolt removal.

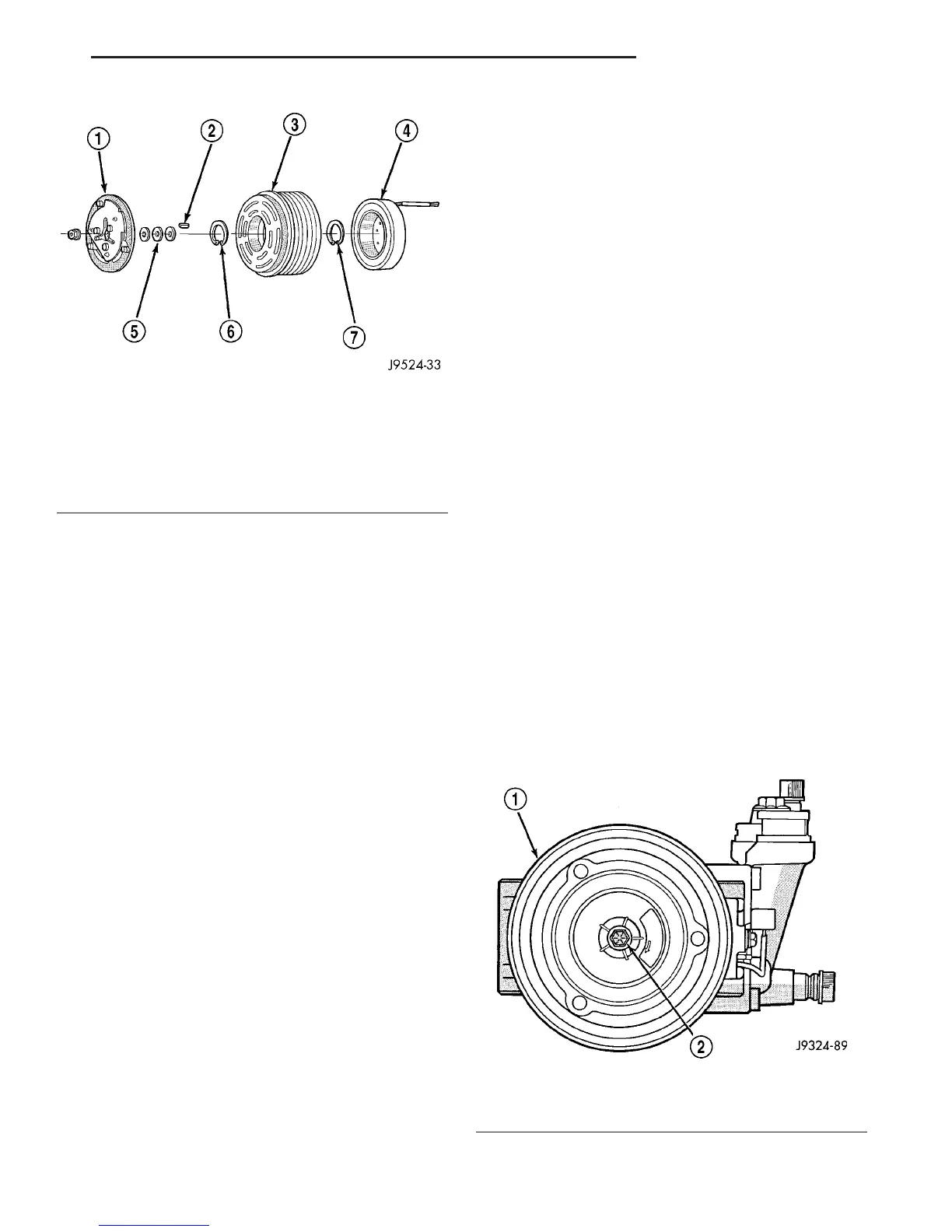

Fig. 1 Compressor Clutch — Typical

1 - CLUTCH PLATE

2 - SHAFT KEY

3 - PULLEY AND BEARING

4 - CLUTCH COIL

5 - CLUTCH SHIMS

6 - SNAP RING

7 - SNAP RING

Fig. 2 Compressor Shaft Bolt and Clutch Plate

1 - COMPRESSOR CLUTCH PLATE

2 - COMPRESSOR SHAFT BOLT

VA CONTROLS - FRONT 24 - 9

A/C COMPRESSOR CLUTCH (Continued)

Loading...

Loading...