REMOVAL

REMOVAL

WARNING: HIGH PRESSURE FUEL LINES DELIVER

DIESEL FUEL UNDER EXTREME PRESSURE FROM

THE INJECTION PUMP TO THE FUEL INJECTORS.

THIS MAY BE AS HIGH AS 23,000PSI (1600)BAR.

USE EXTREME CAUTION WHEN INSPECTING FOR

HIGH PRESSURE FUEL LEAKS. FUEL UNDER THIS

AMOUNT OF PRESSURE CAN PENETRATE SKIN

CAUSING PERSONAL INJURY OR DEATH. INSPECT

FOR HIGH PRESSURE LEAKS WITH A SHEET OF

CARD BOARD. WEAR SAFETY GOGGLES AND

ADEQUATE PROTECTIVE CLOTHING WHEN SER-

VICING THE FUEL SYSTEM.

(1) Disconnect the negative battery cable.

(2) Disconnect the fuel rail pressure sensor wiring

harness connector.

(3) Unbolt fuel rail pressure sensor from the hous-

ing and remove together with the seal.

REMOVAL

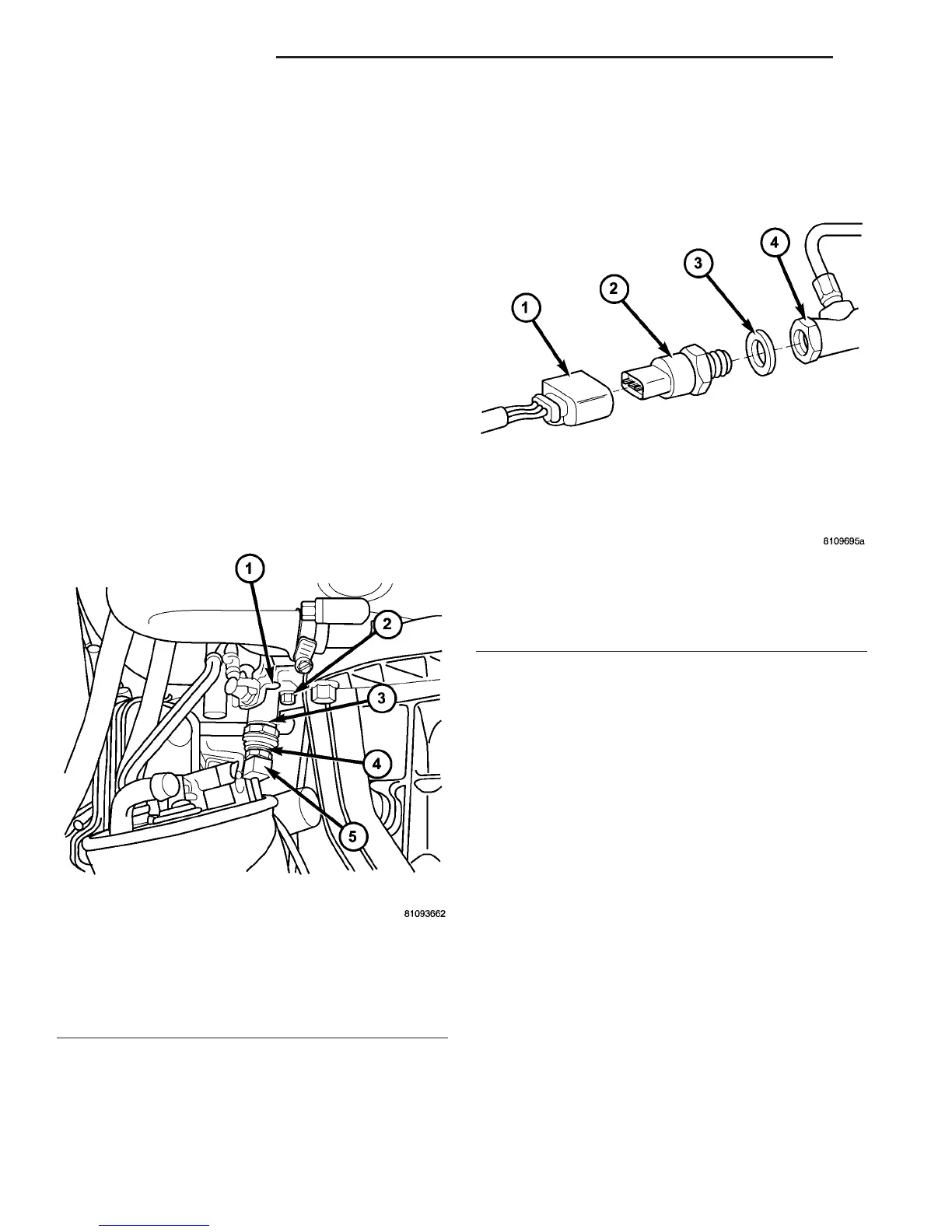

(1) (Refer to 14 - FUEL SYSTEM/FUEL INJEC-

TION - WARNING) Disconnect the negative battery

cable.

(2) Remove the mixing housing.

(3) Unplug the sensor (Fig. 13).

(4) Counter-hold the threaded connection at the

fuel rail and unscrew the sensor (Fig. 13).

INSTALLATION

INSTALLATION

WARNING: HIGH PRESSURE FUEL LINES DELIVER

DIESEL FUEL UNDER EXTREME PRESSURE FROM

THE INJECTION PUMP TO THE FUEL INJECTORS.

THIS MAY BE AS HIGH AS 23,000PSI (1600)BAR.

USE EXTREME CAUTION WHEN INSPECTING FOR

HIGH PRESSURE FUEL LEAKS. FUEL UNDER THIS

AMOUNT OF PRESSURE CAN PENETRATE SKIN

CAUSING PERSONAL INJURY OR DEATH. INSPECT

FOR HIGH PRESSURE LEAKS WITH A SHEET OF

CARD BOARD. WEAR SAFETY GOGGLES AND

ADEQUATE PROTECTIVE CLOTHING WHEN SER-

VICING THE FUEL SYSTEM.

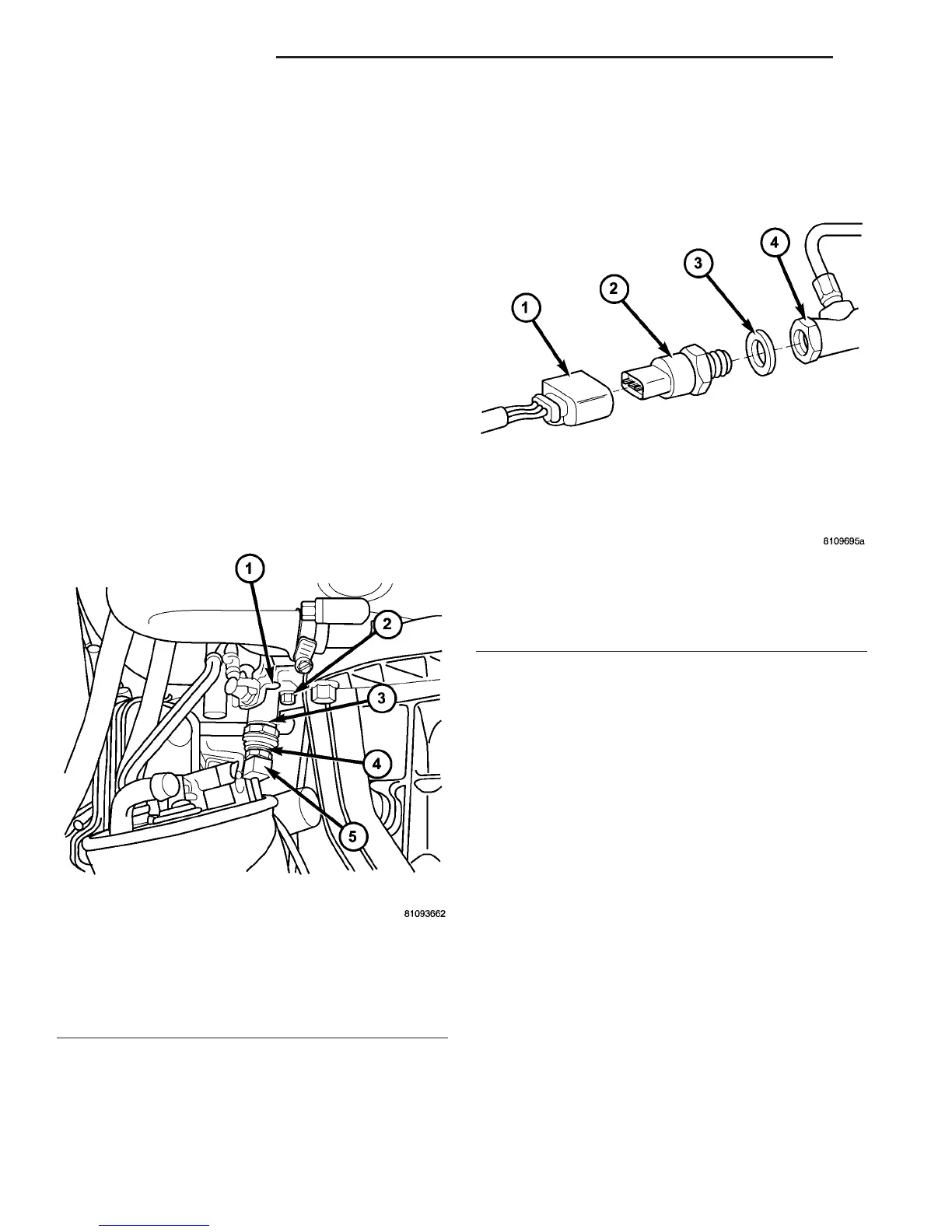

(1) Clean sealing surfaces.

(2) Install new seal and lubricate with clean diesel

fuel.

(3) Properly position sensor and install retaining

bolt (Fig. 12).

(4) Connect wiring harness connector (Fig. 12).

(5) Connect negative battery cable.

Fig. 12 FUEL PRESSURE SENSOR

1 - HOUSING

2 - BOLT

3 - SEALING RING

4 - FUEL RAIL PRESSURE SENSOR

5 - CONNECTOR

Fig. 13 FUEL RAIL PRESSURE SENSOR

1 - WIRING CONNECTOR

2 - FUEL RAIL PRESSURE SENSOR

3 - SEALING RING

4 - FUEL RAIL

14 - 26 FUEL INJECTION VA

FUEL PRESSURE SENSOR (Continued)

Loading...

Loading...