REMOVAL

CAUTION: Do not attempt to check belt tension with

a belt tension gauge on vehicles equipped with an

automatic belt tensioner.

NOTE: The belt routing schematics are published

from the latest information available at the time of

publication. If anything differs between these sche-

matics and the Belt Routing Label, use the sche-

matics on Belt Routing Label.This label is located in

the engine compartment.

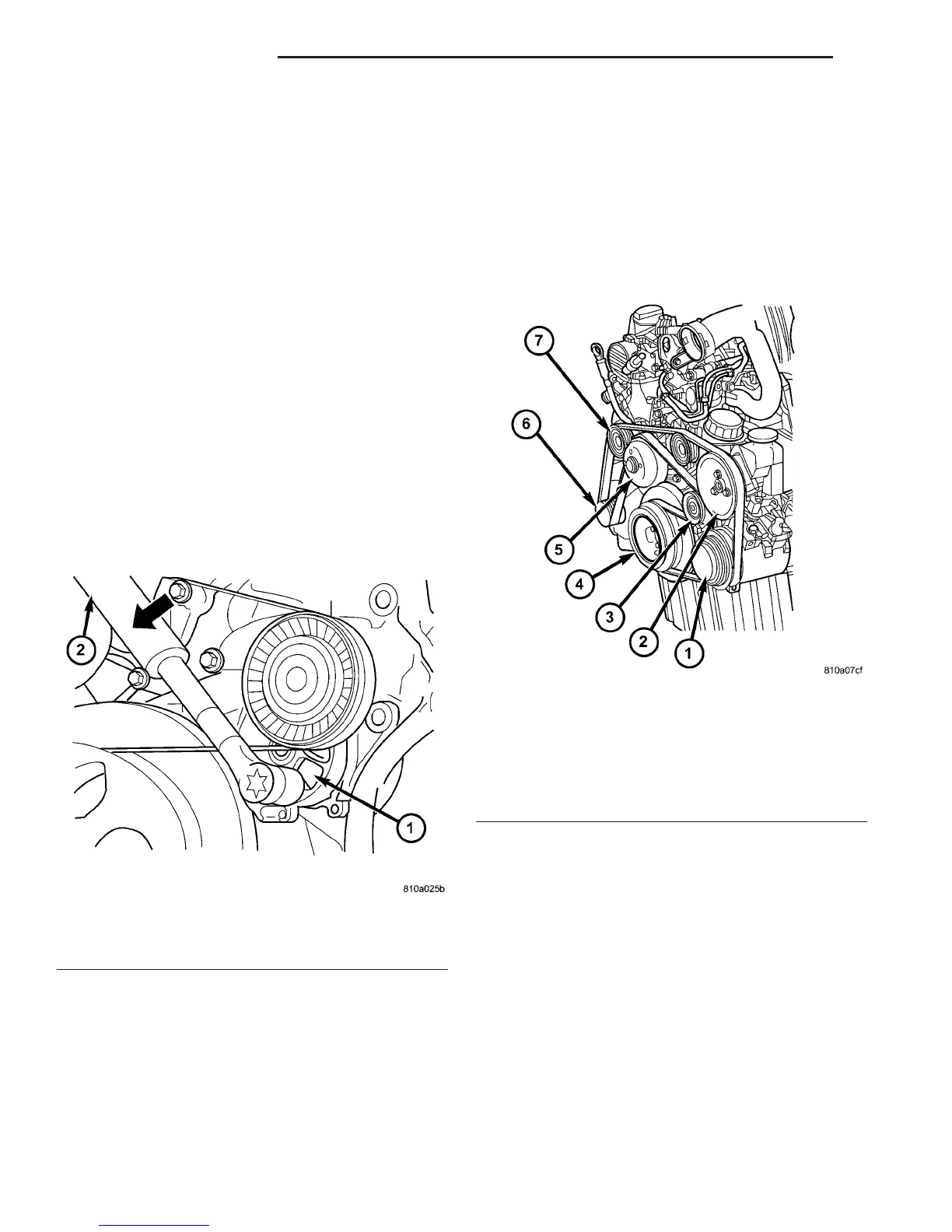

(1) A 3/8 inch square hole is provided in the auto-

matic belt tensioner. Attach a 3/8 inch drive-long

handle ratchet to this hole (Fig. 2).

(2) Rotate ratchet and tensioner assembly counter-

clockwise (as viewed from front) until tension has

been relieved from belt (Fig. 2).

(3) Remove belt from water pump pulley first.

(4) Remove belt from vehicle.

INSTALLATION

CAUTION: When installing the accessory drive belt,

the belt must be the correct length and routed cor-

rectly. If not, engine may overheat due to water

pump rotating in wrong direction.

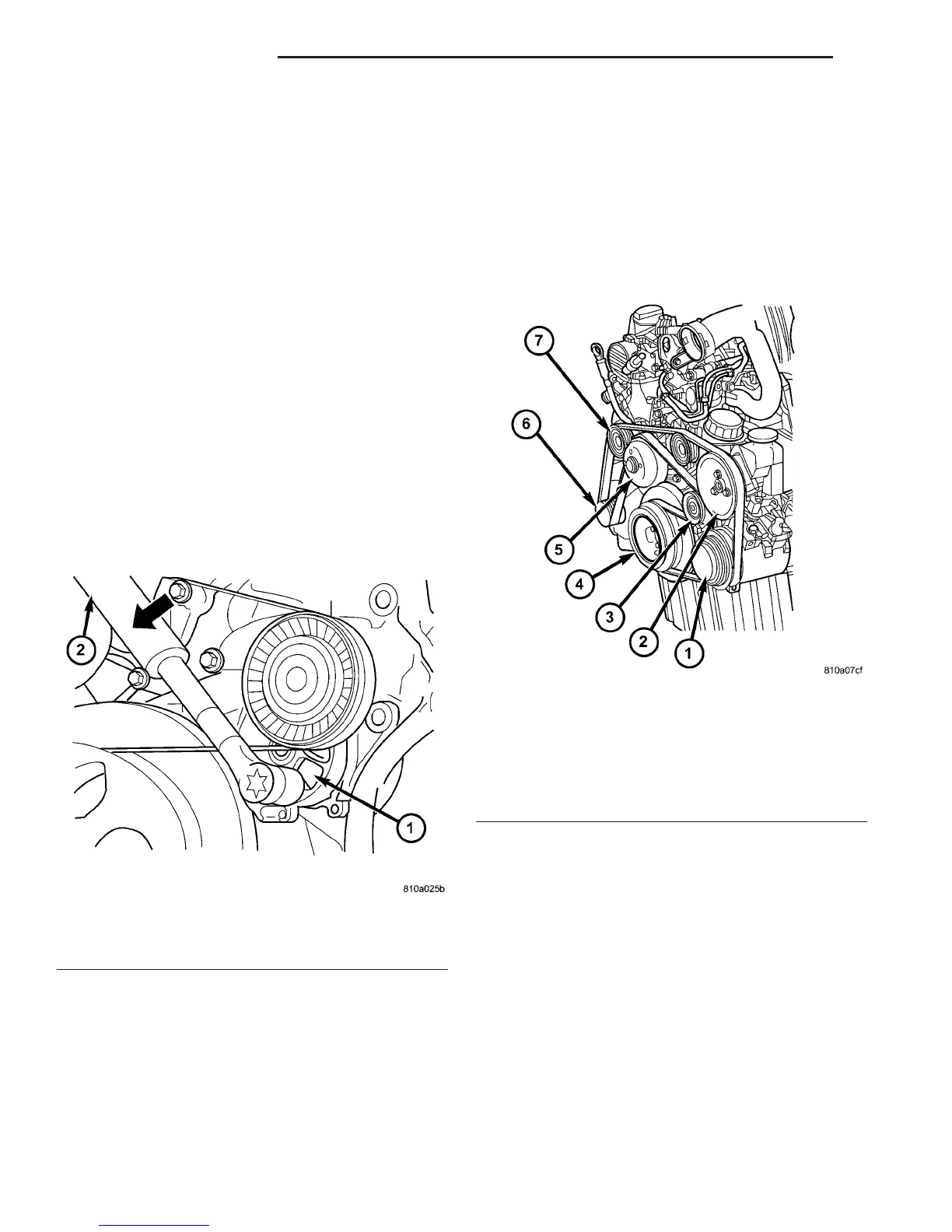

(1) Position drive belt over all pulleys except

water pump pulley (Fig. 3).

(2) Attach a 3/8 inch ratchet to tensioner.

(3) Rotate ratchet and belt tensioner counterclock-

wise. Place belt over water pump pulley. Let ten-

sioner rotate back into place. Remove ratchet. Be

sure belt is properly seated on all pulleys.

Fig. 2 DRIVE BELT TENSIONER

1 - ACCESSORY DRIVE BELT TENSIONER

2 - RATCHET WRENCH

Fig. 3 ACCESSORY DRIVE BELT ROUTING

1 - A/C COMPRESSOR

2 - POWER STEERING

3 - DRIVE BELT TENSIONER

4 - CRANKSHAFT PULLEY

5 - WATER PUMP PULLEY

6 - GENERATOR

7 - IDLER PULLEY

7 - 8 ACCESSORY DRIVE VA

DRIVE BELTS (Continued)

Loading...

Loading...