(1) Reconnect and latch the vehicle wire harness

connector for the ACM to the ACM connector recep-

tacle located on the left facing side of the module

(Fig. 12).

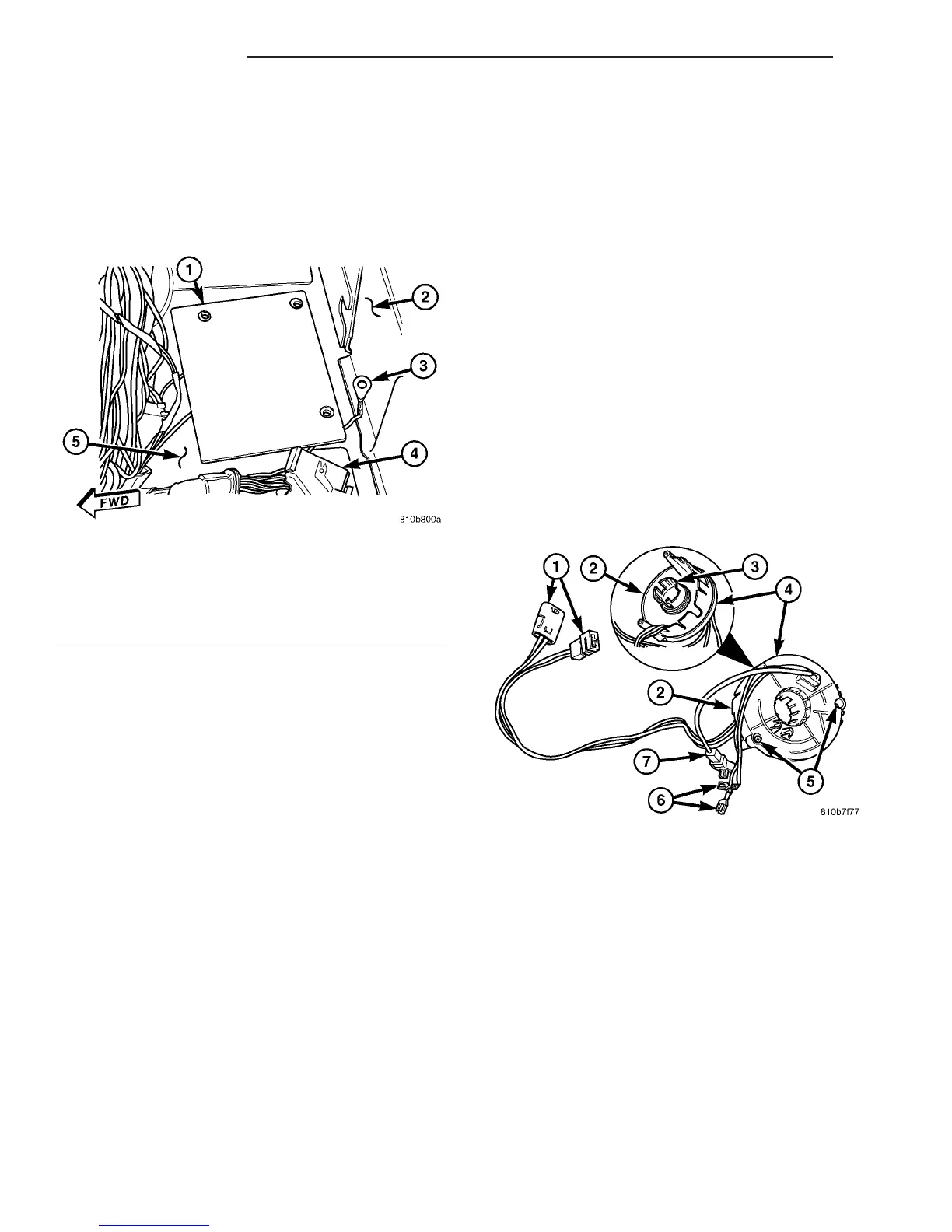

(2) Carefully position the ACM cover base plate

onto the mounting bracket that is welded onto the

floor panel under the driver side front seat (Fig. 13).

(3) Carefully position the ACM onto the ACM cover

base plate. When the ACM is correctly positioned, the

three ACM mounting tabs will be aligned with the

holes in the cover base plate and the mounting

bracket, and the orientation arrow on the ACM label

will be pointed forward in the vehicle.

(4) Install and tighten the three screws that secure

the ACM to the mounting bracket that is welded onto

the floor panel within the driver side front seat riser.

Be certain that the ground eyelet terminal is

installed under the screw for the left rear mounting

tab. Tighten the screws to 12 N·m (105 in. lbs.).

(5) Position the ACM cover over the ACM and

press it down firmly and evenly until it snaps into

position over the ACM cover base plate (Fig. 11).

(6) Position the control module bracket onto the

top of the driver side seat riser (Fig. 10).

(7) Install and tighten the two screws that secure

the control module bracket to the top of the seat riser

under the driver side front seat. Tighten the screws

to 2 N·m (18 in. lbs.).

(8) Position the cover panel onto the top of the

driver side seat riser (Fig. 9).

(9) Install and tighten the two screws that secure

the cover panel to the top of the seat riser under the

driver side front seat. Tighten the screws to 2 N·m

(18 in. lbs.).

(10) Move the driver side front seat back to its

driving position.

(11) Do not reconnect the battery negative cable at

this time. The supplemental restraint system verifi-

cation test procedure should be performed following

service of any supplemental restraint system compo-

nent. (Refer to 8 - ELECTRICAL/RESTRAINTS -

STANDARD PROCEDURE - VERIFICATION TEST).

NOTE: If the Airbag Control Module (ACM) has been

replaced with a new unit, it will be necessary to ini-

tialize the new ACM. In order to function properly,

the ACM must be programmed for the correct stan-

dard and optional supplemental restraint system

components installed in the vehicle. To initialize the

ACM, a DRBIIIT scan tool is required. Refer to the

appropriate diagnostic information.

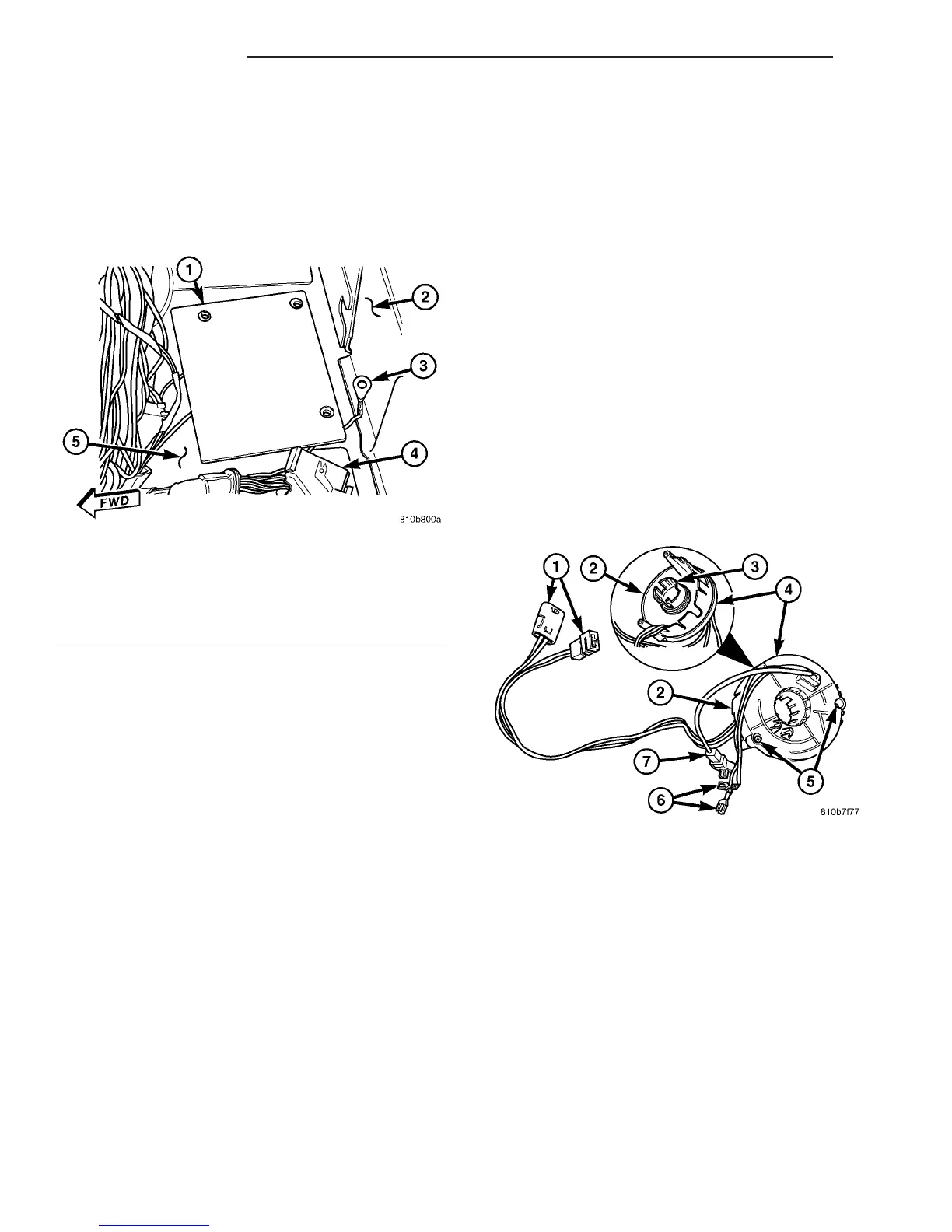

CLOCKSPRING

DESCRIPTION

The clockspring assembly is secured with two

screws onto the multi-function switch housing near

the top of the steering column directly below the

steering wheel (Fig. 14). The clockspring consists of a

flat, round molded plastic case that contains a spool-

like molded plastic rotor with a large exposed hub

covering the entire upper surface of the case. The

rotor hub has a large center hole that is internally

ribbed to engage splines on the upper steering col-

umn shaft, and two small clearance holes that pro-

Fig. 13 ACM Cover Base Plate

1 - BASE PLATE

2 - SEAT RISER

3 - GROUND EYELET TERMINAL

4 - ACM CONNECTOR

5 - FLOOR PANEL

Fig. 14 Clockspring

1 - PIGTAIL WIRE CONNECTOR (2)

2 - CASE

3 - CANCEL CAM

4 - ROTOR

5 - SCREW (2)

6 - HORN SWITCH CONNECTOR (2)

7 - AIRBAG CONNECTOR

8O - 12 RESTRAINTS VA

AIRBAG CONTROL MODULE (Continued)

Loading...

Loading...