(5) If runout is still excessive, the following proce-

dures must be done.

• If the high spot is within 101.6 mm (4.0 in.) of

the first spot and is still excessive, replace the tire.

• If the high spot is within 101.6 mm (4.0 in.) of

the first spot on the wheel, the wheel may be out of

specifications. Refer to Wheel and Tire Runout.

• If the high spot is NOT within 101.6 mm (4.0

in.) of either high spot, draw an arrow on the tread

from second high spot to first. Break down the tire

and remount it 90 degrees on rim in that direction

(Fig. 6). This procedure will normally reduce the

runout to an acceptable amount, if not replace the

rim.

STANDARD PROCEDURE - TIRE AND WHEEL

BALANCE

It is recommended that a two plane service

dynamic balancer be used when a tire and wheel

assembly require balancing. Refer to balancer opera-

tion instructions for proper cone mounting proce-

dures. Typically use front cone mounting method for

steel wheels. For aluminum wheel use back cone

mounting method without cone spring.

NOTE: Static should be used only when a two plane

balancer is not available.

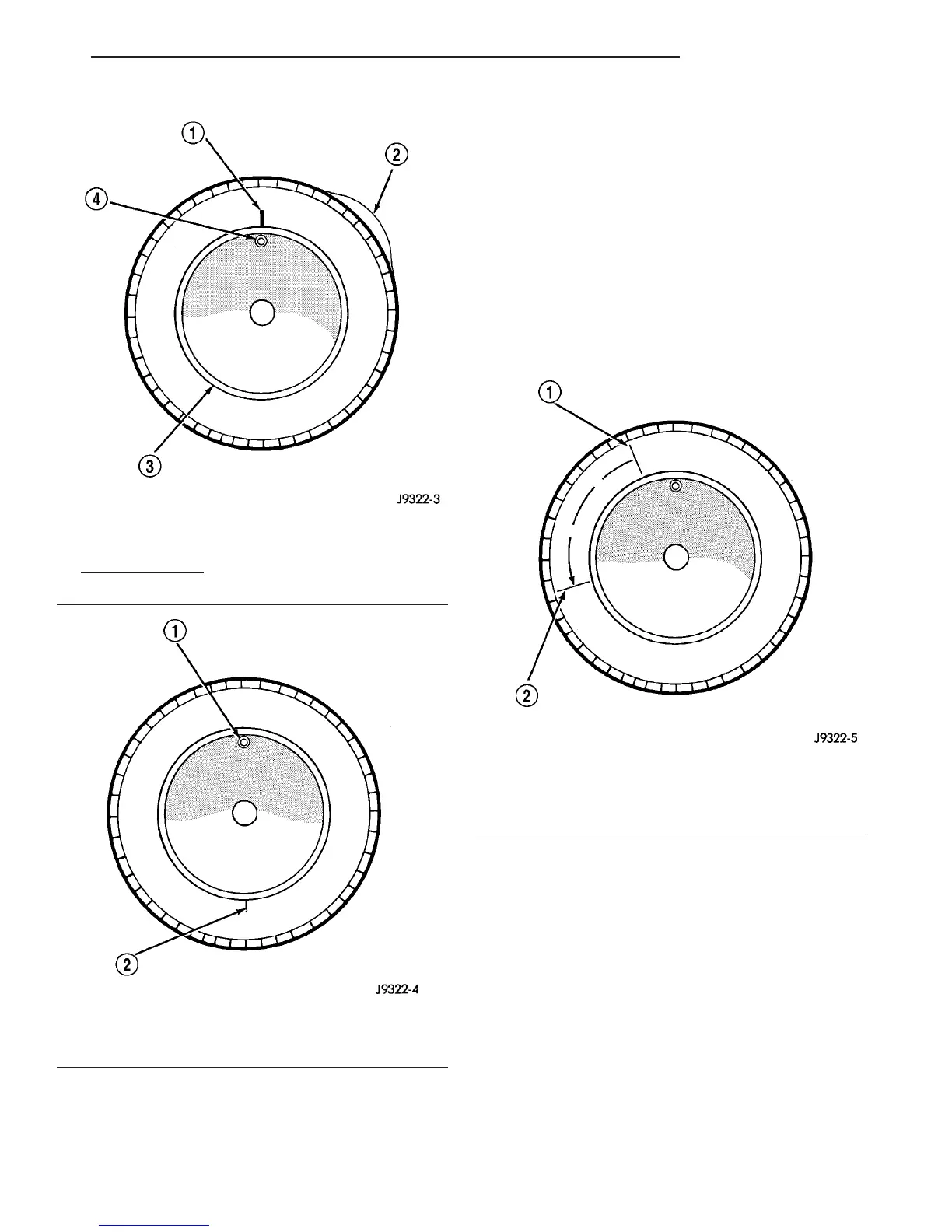

Fig. 4 First Measurement On Tire

1 - REFERENCE MARK

2 - 1ST MEASUREMENT HIGH SPOT MARK TIRE AND RIM

3 - WHEEL

4 - VALVE STEM

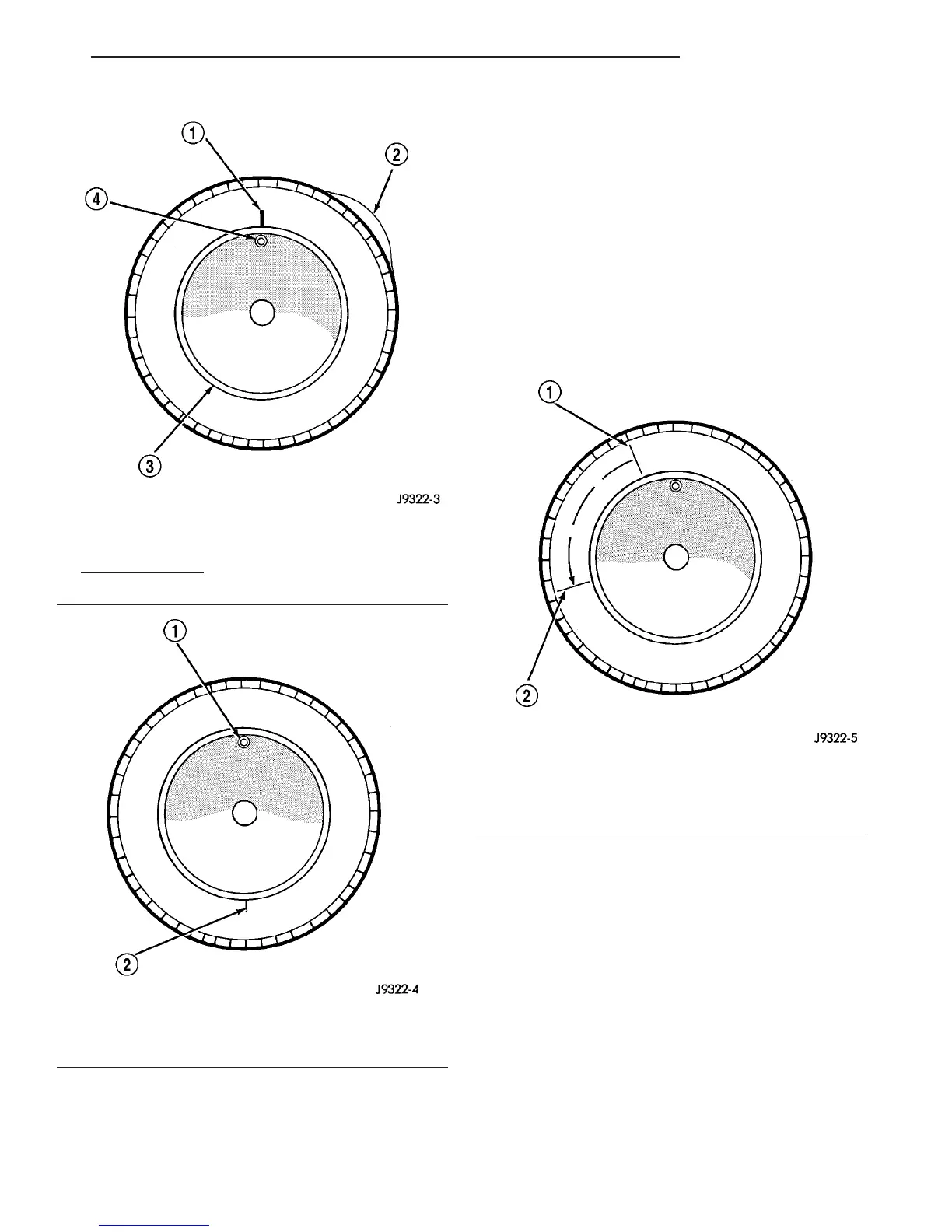

Fig. 5 Remount Tire 180 Degrees

1 - VALVE STEM

2 - REFERENCE MARK

Fig. 6 Remount Tire 90 Degrees In Direction of

Arrow

1 - 2ND HIGH SPOT ON TIRE

2 - 1ST HIGH SPOT ON TIRE

VA TIRES/WHEELS 22 - 3

TIRES/WHEELS (Continued)

Loading...

Loading...