Low turbocharger boost pressure and low engine

performance can be caused by leaks in the charge air

cooler or it’s plumbing. The following procedure out-

lines how to check for leaks in the charge air cooler

system.

(1) Loosen clamp and remove turbocharger to air

inlet duct rubber sleeve from turbocharger.

(2) Insert Special Tool 8442 Adapter into the rub-

ber sleeve. Tighten existing clamp to 8 N·m (72

in.lbs.).

CAUTION: Do not apply more than 138 kpa (20 psi)

air pressure to the charge air cooler system, sever

damage to the charge air cooler system may occur.

(3) Connect regulated air supply to air fitting on

Special Tool 8442 Adapter. Set air pressure to a Max-

imum of 138 kpa (20 psi).

(4) Using soapy water check the air inlet ducts,

rubber sleeves, charge air cooler and intake manifold

for leaks.

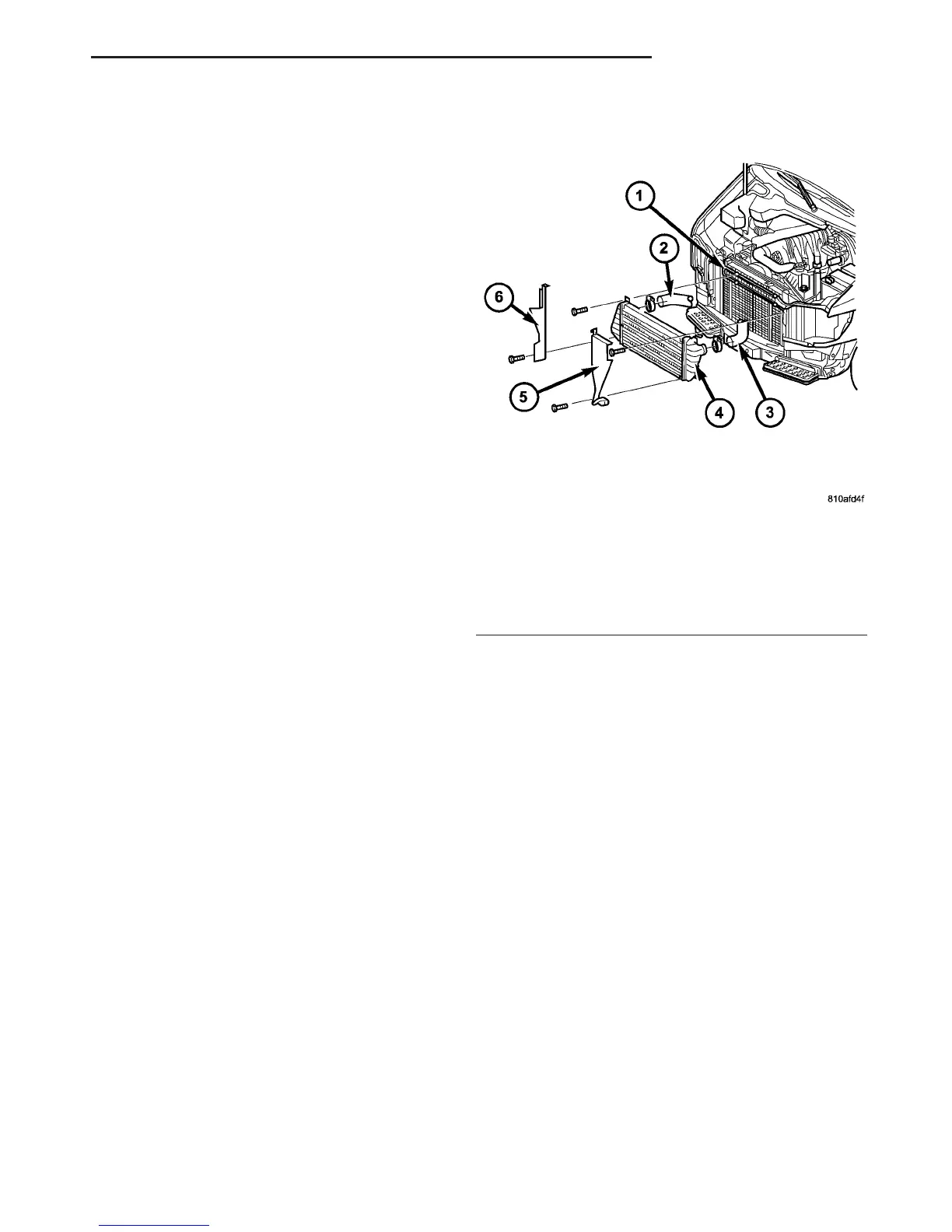

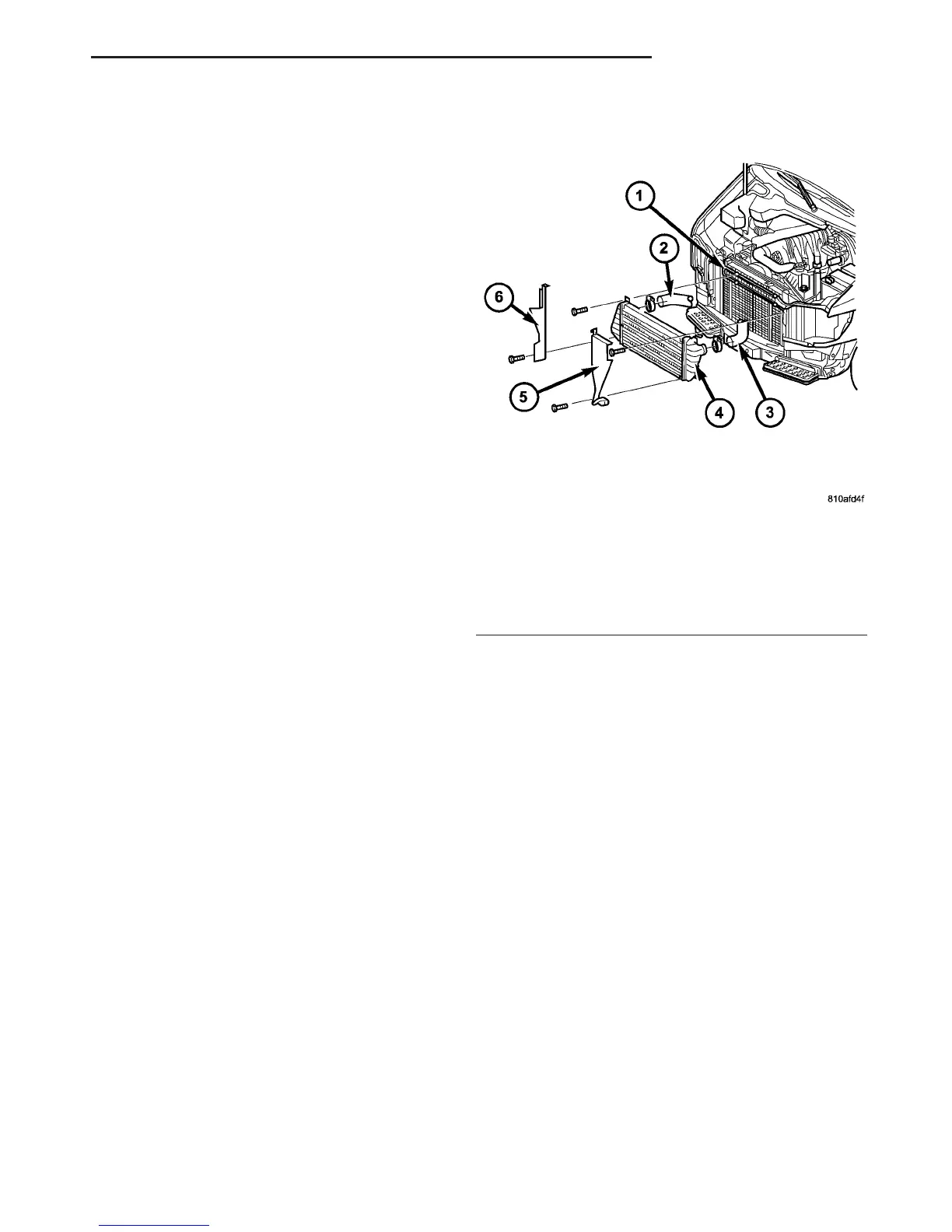

REMOVAL

(1) Remove front bumper.

(2) Remove headlamp assemblies.

(3) Remove front cross member together with front

grille.

(4) Remove left and right radiator trim (Fig. 3).

(5) Disconnect charge air hoses at charge air cooler

(Fig. 3).

(6) Disconnect power steering cooler loop from

charge air cooler (Fig. 3).

(7) Remove charge air cooler from radiator assem-

bly (Fig. 3).

CLEANING

CAUTION: Do not use caustic cleaners to clean the

charge air cooler. Damage to the charge air cooler

will result.

NOTE: If internal debris cannot be removed from

the cooler, the charge air cooler MUST be replaced.

(1) If the engine experiences a turbocharger failure

or any other situation where oil or debris get into the

charge air cooler, the charge air cooler must be

cleaned internally.

(2) Position the charge air cooler so the inlet and

outlet tubes are vertical.

(3) Flush the cooler internally with solvent in the

direction opposite of normal air flow.

(4) Shake the cooler and lightly tap on the end

tanks with a rubber mallet to dislodge trapped

debris.

(5) Continue flushing until all debris or oil are

removed.

(6) Rinse the cooler with hot soapy water to

remove any remaining solvent.

(7) Rinse thoroughly with clean water and blow

dry with compressed air.

INSPECTION

Visually inspect the charge air cooler for cracks,

holes, or damage. Inspect the tubes, fins, and welds

for tears, breaks, or other damage. Replace the

charge air cooler if damage is found.

Pressure test the charge air cooler, using Charge

Air Cooler Tester Kit.

INSTALLATION

(1) Install charge air cooler to radiator (Fig. 3).

(2) Connect power steering cooler loop to charge

air cooler (Fig. 3).

(3) Connect charge air hoses (Fig. 3).

(4) Install both radiator trim pieces (Fig. 3).

(5) Install front grille with front cross member.

(6) Install headlamp assemblies.

(7) Install front bumper.

Fig. 3 CHARGE AIR COOLER

1 - POWER STEERING COOLER LOOP

2 - CHARGE AIR HOSE

3 - CHARGE AIR COOLER HOSE

4 - CHARGE AIR COOLER

5 - LEFT RADIATOR TRIM PANEL

6 - RIGHT RADIATOR TRIM PANEL

VA EXHAUST SYSTEM 11 - 5

CHARGE AIR COOLER AND PLUMBING (Continued)

Loading...

Loading...