WASHERS/FRONT WIPER MOTOR -

INSTALLATION).

(2) Carefully position the wiper linkage module

and wiper motor to the underside of the cowl top

panel as a unit (Fig. 22).

(3) Install and tighten the two screws that secure

the wiper linkage module motor bracket to the flange

on the underside of the cowl top panel. Tighten the

screws to 6 N·m (50 in. lbs.).

(4) Install and tighten the nut and washer that

secures each wiper pivot housing to the outside of the

cowl top panel.

(5) Reconnect the wiper motor pigtail wire connec-

tor to the vehicle wire harness connector.

(6) Reinstall the ventilation housing onto the dash

panel and the underside of the cowl top panel (Fig.

21).

(7) Reinstall the wiper arms onto the wiper pivots.

(Refer to 8 - ELECTRICAL/WIPERS/WASHERS/

WIPER ARM - INSTALLATION).

(8) Reconnect the battery negative cable.

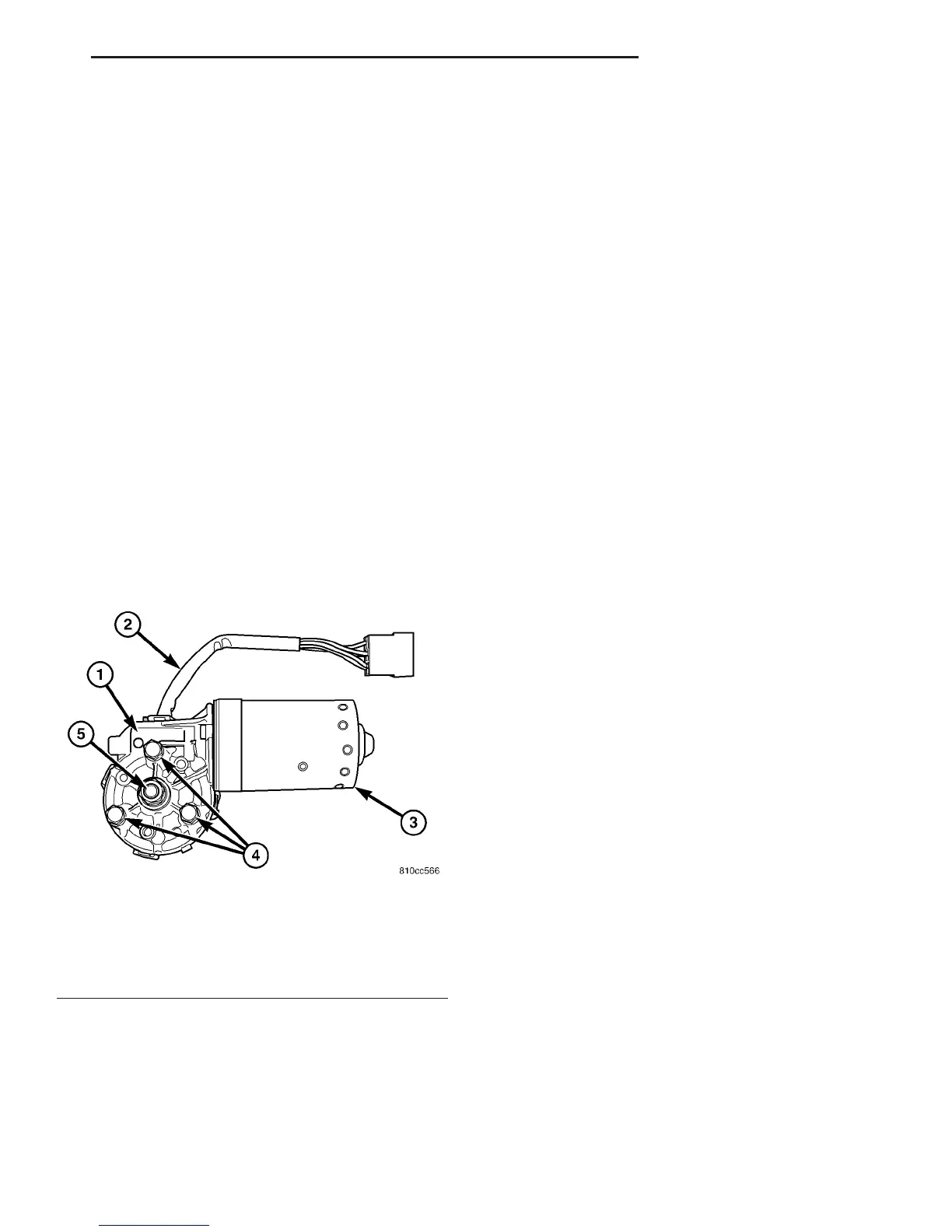

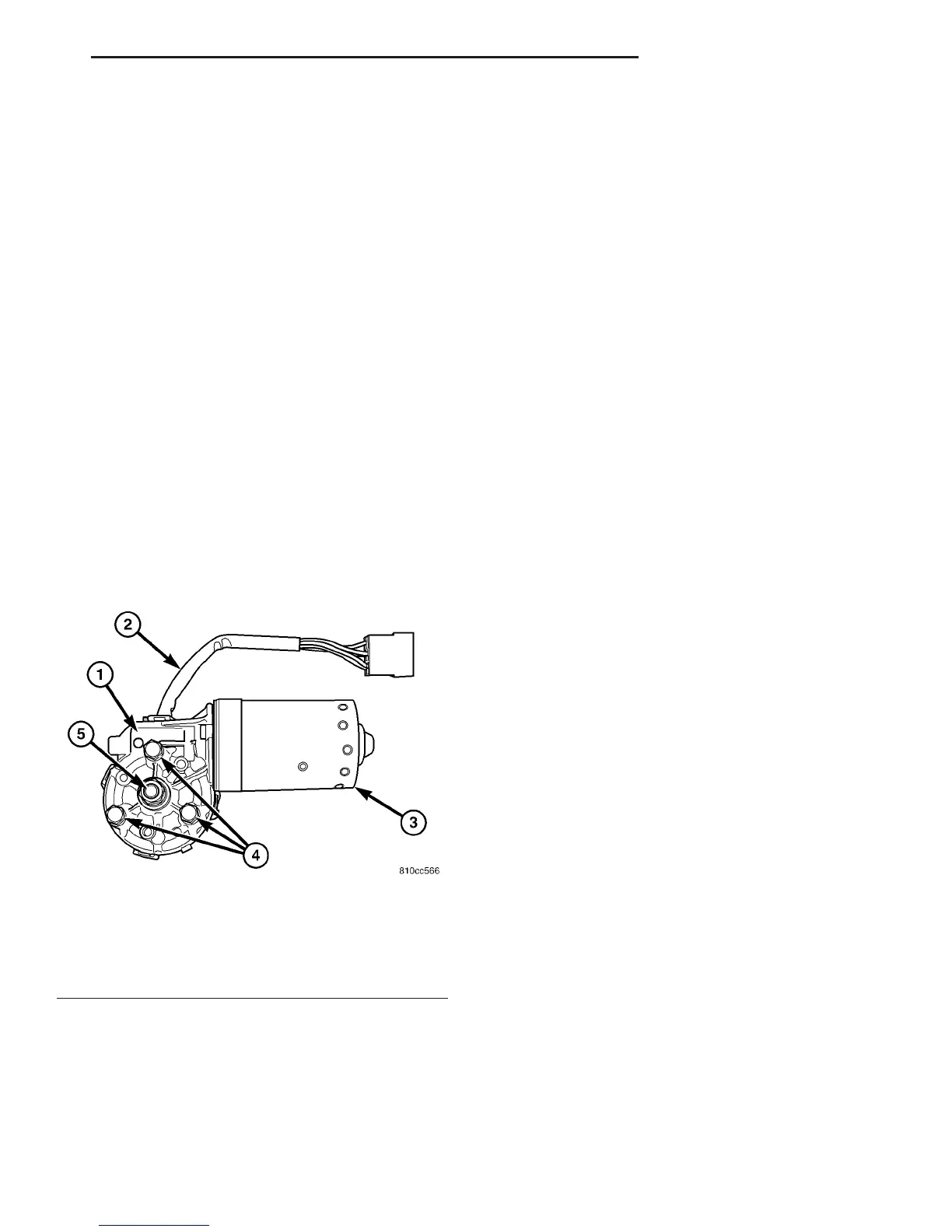

WIPER MOTOR

DESCRIPTION

The wiper motor is secured with three screws to a

motor bracket integral to the wiper linkage module

bracket located below the cowl top panel in the

engine compartment (Fig. 23). The wiper motor out-

put shaft passes through a hole in the motor bracket,

where a nut secures the wiper motor crank arm to

the motor output shaft. The two-speed permanent

magnet wiper motor features an integral transmis-

sion, an internal park switch, and an internal Posi-

tive Temperature Coefficient (PTC) circuit breaker.

The wiper motor cannot be adjusted or repaired. If

any component of the motor is faulty or damaged, the

entire wiper motor unit must be replaced.

OPERATION

The wiper motor operation is controlled by the

vehicle operator through battery current inputs

received by the wiper motor from the wiper switch

circuitry of the multi-function switch on the top of

the steering column, and from the wiper relay on the

fuse block underneath the steering column. The

wiper motor speed is controlled by current flow to

either the low speed or the high speed set of brushes.

The automatic resetting circuit breaker protects the

motor from overloads.

The park switch consists of a contact disc and

three contacts. The contact disc is mechanically fas-

tened to and rotated with a gear in the wiper motor

transmission. Two input contacts alternately close

the wiper park switch sense output circuit contact to

ground or to battery current, depending upon the

position of the wipers on the glass. This feature

allows the intermittent wipe logic circuit to monitor

the position and the cycles of the wiper motor to pro-

vide the intermittent wipe and wipe-after-wash

modes, as well as allowing the motor to complete its

current wipe cycle after the wiper system has been

turned Off and park the wiper blades in the lowest

portion of the wipe pattern.

The wiper motor may be diagnosed using conven-

tional diagnostic tools and methods.

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Disconnect the vehicle wire harness connector

for the wiper motor from the motor pigtail wire con-

nector (Fig. 24).

(3) Remove the nut that secures the motor crank

arm to the wiper motor output shaft.

(4) If this wiper motor is to be reinstalled, make

an index mark between the wiper motor output shaft

and the motor crank arm using a suitable marker.

(5) Disengage the motor crank arm from the wiper

motor output shaft.

(6) Remove the three screws that secure the wiper

motor to the wiper linkage module motor bracket.

(7) Remove the wiper motor from the wiper link-

age module motor bracket.

INSTALLATION

(1) Position the wiper motor to the underside of

the wiper linkage module motor bracket (Fig. 24).

Fig. 23 Wiper Motor

1 - TRANSMISSION

2 - PIGTAIL WIRE

3 - MOTOR

4 - SCREW (3)

5 - OUTPUT SHAFT

VA WIPERS/WASHERS 8R - 19

WIPER LINKAGE (Continued)

Loading...

Loading...