REMOVAL

(1) Disconnect and isolate the negative battery

cable.

(2) Remove the gear selector bezel trim. Refer to

the Body section for the procedure.

(3) Remove the storage bin. Refer to the Body sec-

tion for the procedure.

(4) Remove the switch bezel retaining screw and

remove the switch bezel from the instrument panel.

Refer to the Body section for the procedure.

(5) Disconnect electrical connections.

(6) Working from the underside of the switch, gen-

tly rock the switch back and forth out of its mounting

location in the switch bezel.

INSTALLATION

(1) Install the heated seat switch in its mounting

location in the switch bezel.

(2) Connect electrical connections.

(3) Position the switch bezel and install the retain-

ing screw. Refer to the Body section for the proce-

dure.

(4) Install the storage bin. Refer to the Body sec-

tion for the procedure.

(5) Install the gear selector bezel trim. Refer to the

Body section for the procedure.

(6) Connect the negative battery cable.

HEATED SEAT ELEMENT

DESCRIPTION

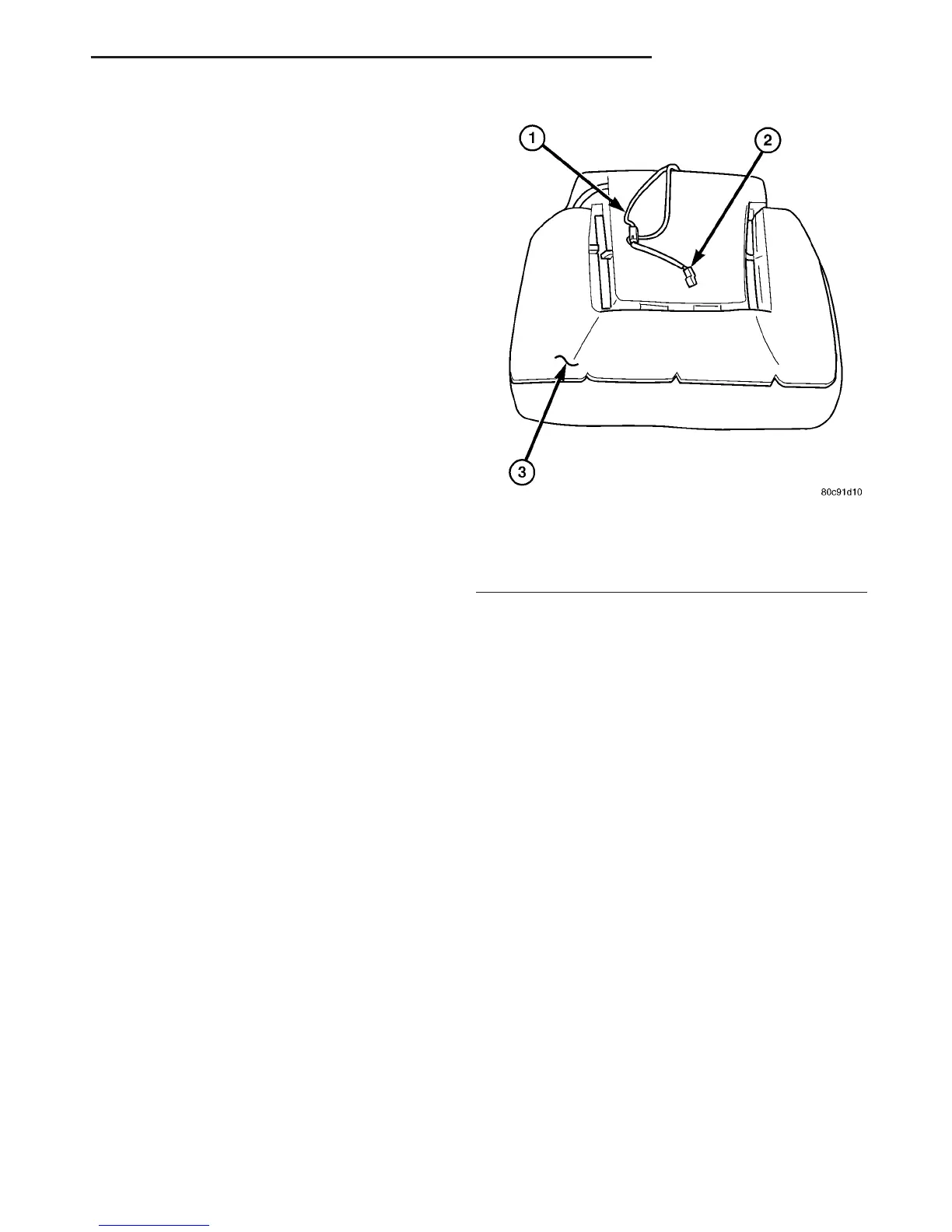

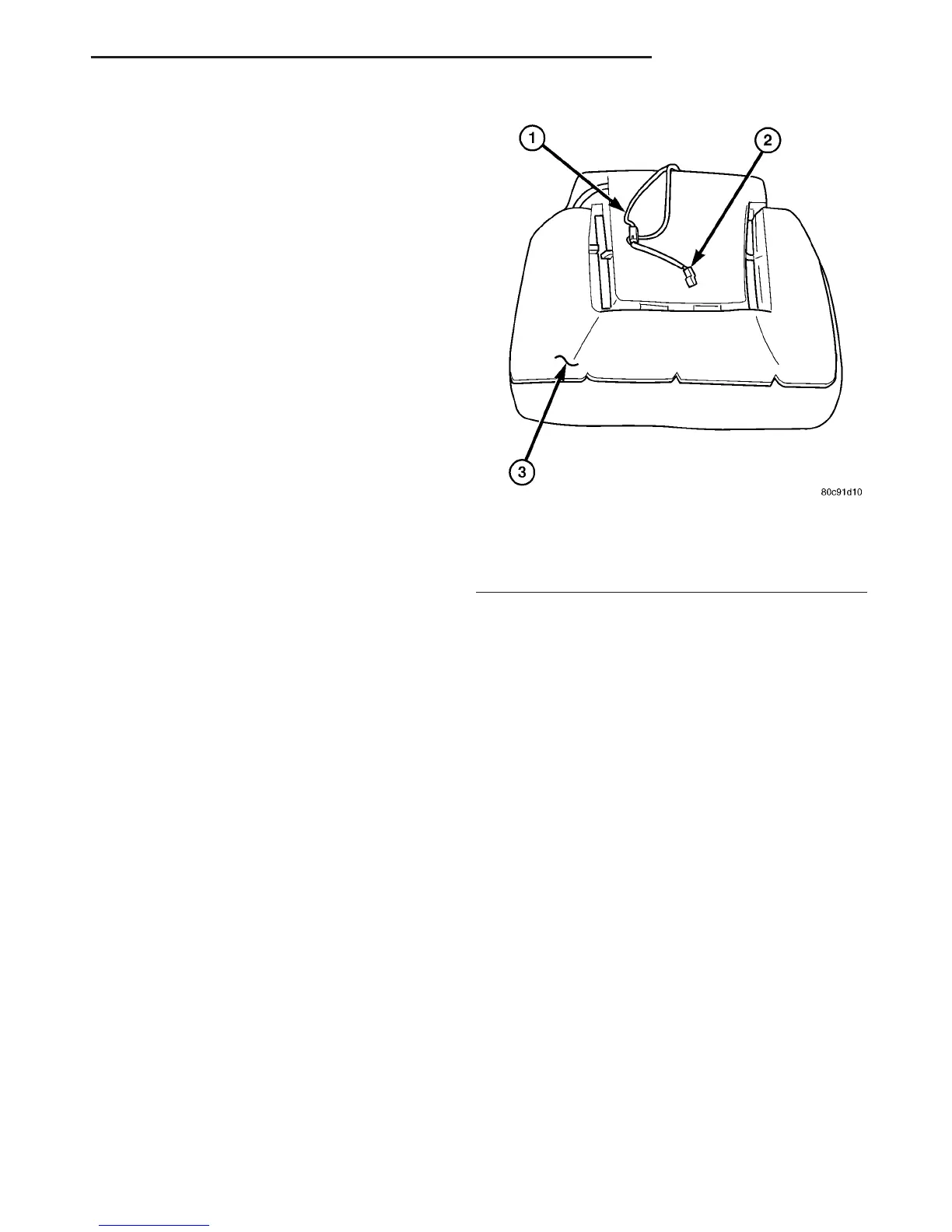

The heated seat system includes two seat heating

elements in each front seat, one for the seat cushion

(Fig. 1) and the other for the seat back. All models

use two resistor wire heating elements for each seat

that are connected in series with the Heated Seat

Relay. The temperature sensor is a Negative Temper-

ature Coefficient (NTC) thermistor. One temperature

sensor is used for each seat, and it is located in the

seat cushion heating element for all models.

The seat heating elements are glued onto the seat

and seat back cushions. The heated seat elements

and the temperature sensor cannot be adjusted or

repaired and, if faulty or damaged a new seat assem-

bly must be installed.

OPERATION

The heated seat elements resist the flow of electri-

cal current. When battery current is passed through

the elements, the energy lost by the resistance of the

elements is released in the form of heat. The heated

seat temperature sensor is a NTC thermistor. When

the temperature of the seat cushion cover rises, the

resistance of the sensor decreases. The heated seat

relay uses this temperature sensor input to monitor

the temperature of the seat, and regulates the cur-

rent flow to the seat heating elements accordingly.

DIAGNOSIS AND TESTING - HEATED SEAT

ELEMENT

For complete circuit diagrams, refer to Wiring.

NOTE: When checking heated seat elements for

continuity, be certain to move the heating element

being checked. Moving the element, such as sitting

in the seat will eliminate the possibility of an inter-

mittent open in the element which would only be

evident if the element was in a certain position.

Failure to check the element in various positions

could result in an incomplete test.

(1) Disconnect and isolate the battery negative

cable. Disconnect the heated seat element wire har-

ness connector from under the seat cushion. Check

for continuity between the seat heater driver circuit

and ground. There should be continuity, less than 7

ohms. If OK, go to Step 2. If not OK, replace the seat

assembly.

(2) Check for continuity between the seat heater

B+ driver circuit cavity and the seat back frame.

There should be no continuity. If OK, heating ele-

ment is OK at this time. If not OK, replace the seat

assembly.

Fig. 1 Heated Seat Element - Typical

1 - Seat Back Wire Harness

2 - Heated Seat Wire Harness Connector

3 - Heated Seat Cushion Element

VA HEATED SYSTEMS 8G - 3

DRIVER HEATED SEAT SWITCH (Continued)

Loading...

Loading...