REMOVAL

WARNING: HIGH-PRESSURE FUEL LINES DELIVER

DIESEL FUEL UNDER EXTREME PRESSURE FROM

THE INJECTION PUMP TO THE FUEL INJECTORS.

THIS MAY BE AS HIGH AS 1600BAR (23,200 PSI).

USE EXTREME CAUTION WHEN INSPECTING FOR

HIGH-PRESSURE FUEL LEAKS. FUEL UNDER THIS

AMOUNT OF PRESSURE CAN PENETRATE SKIN

CAUSING PERSONAL INJURY OR DEATH. INSPECT

FOR HIGH-PRESSURE LEAKS WITH A SHEET OF

CARD BOARD. WEAR SAFETY GOGGLES AND

ADEQUATE PROTECTIVE CLOTHING WHEN SER-

VICING FUEL SYSTEM.

WARNING: NO SPARKS, OPEN FLAMES OR SMOK-

ING. RISK OF POISONING FROM INHALING AND

SWALLOWING FUEL. RISK OF INJURY TO EYES

AND SKIN FROM CONTACT WITH FUEL. POUR

FUELS ONLY INTO SUITABLE AND APPROPRI-

ATELY MARKED CONTAINERS. WEAR PROTECTIVE

CLOTHING.

(1) Disconnect negative battery cable.

(2) Remove fuel rail (Refer to 14 - FUEL SYSTEM/

FUEL INJECTION/FUEL INJECTOR - REMOVAL).

(3) Clamp fuel rail securely in vise with protective

jaws.

NOTE: Once removed, the pressure solenoid must

always be replaced.

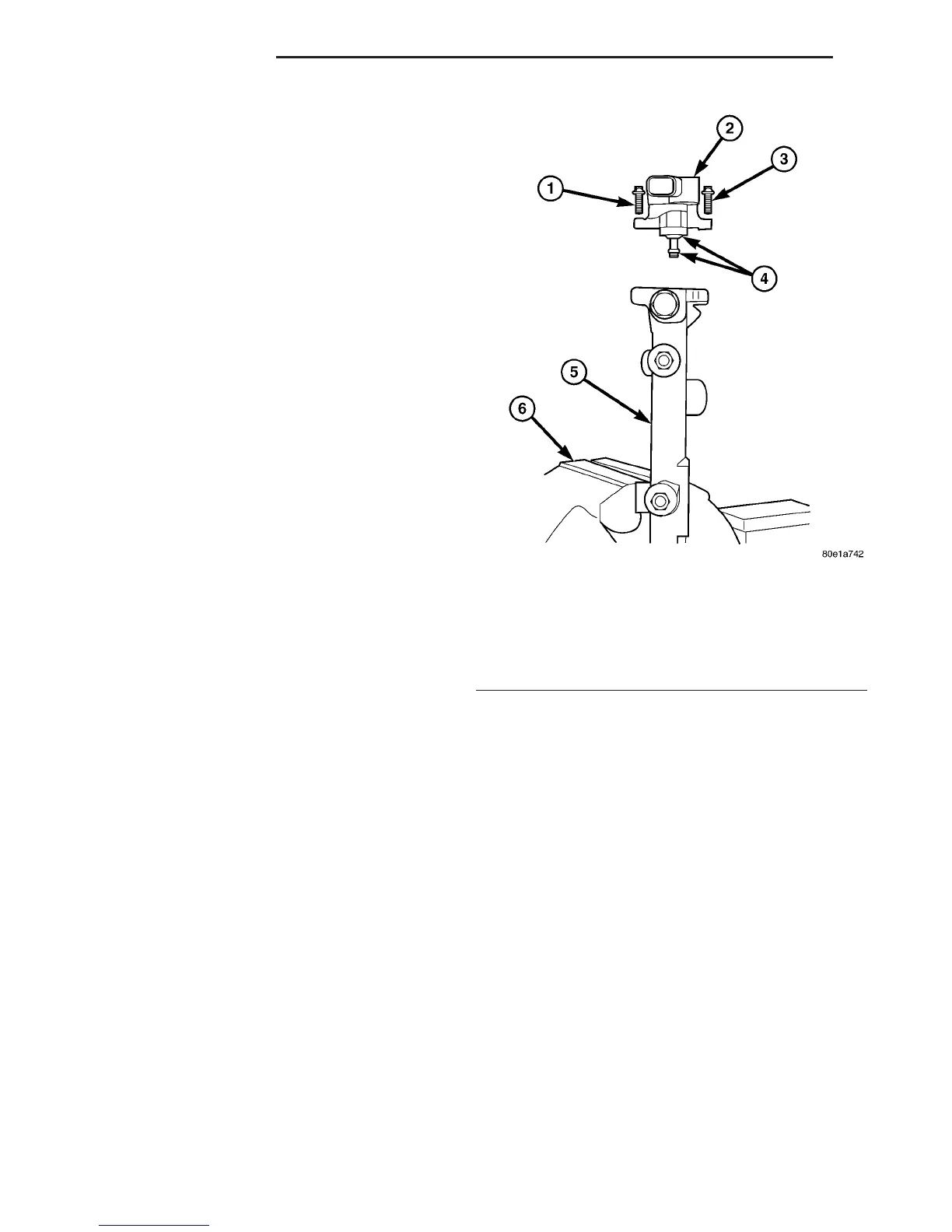

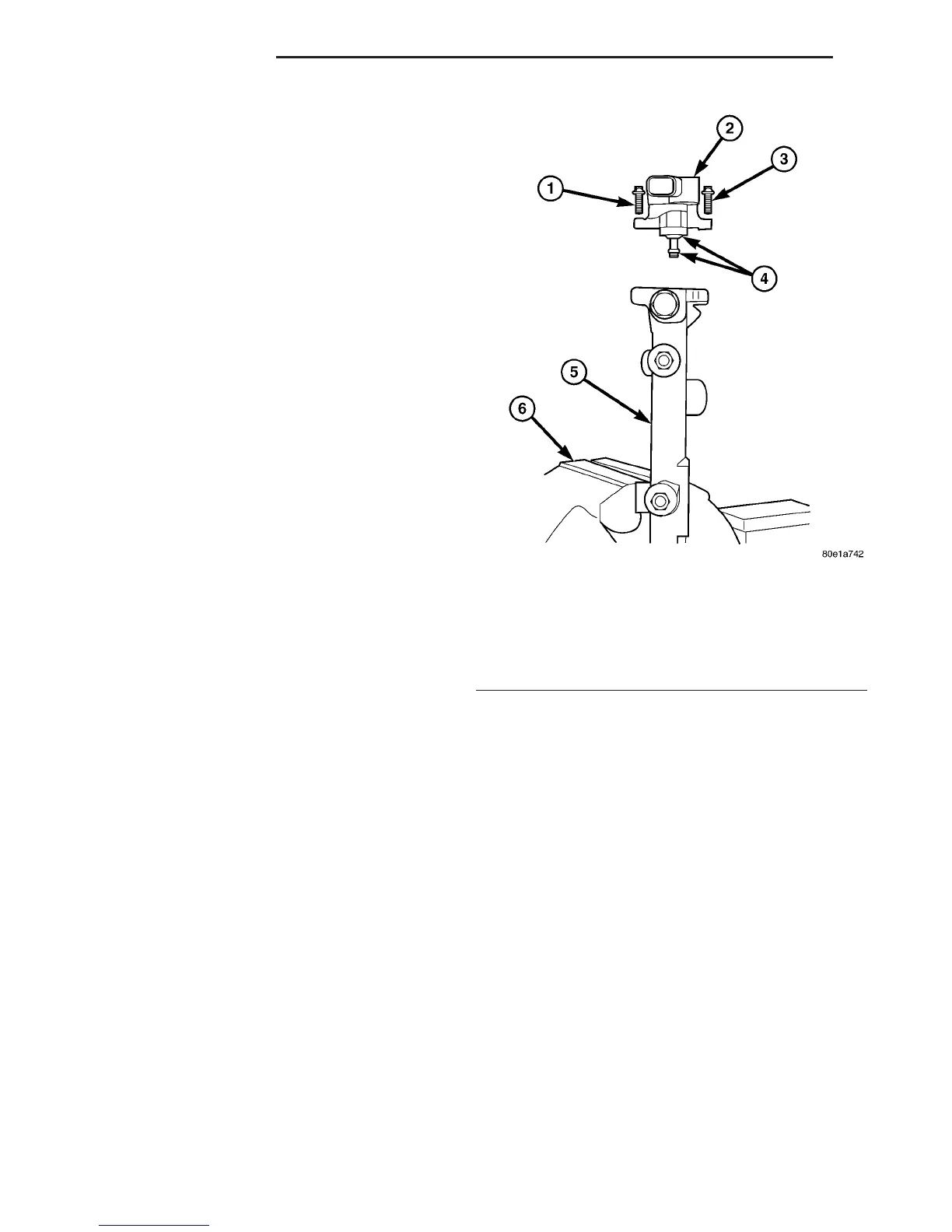

(4) Remove fuel pressure solenoid retaining screws

and remove solenoid (Fig. 16).

INSTALLATION

WARNING: HIGH-PRESSURE FUEL LINES DELIVER

DIESEL FUEL UNDER EXTREME PRESSURE FROM

THE INJECTION PUMP TO THE FUEL INJECTORS.

THIS MAY BE AS HIGH AS 1600BAR (23,200 PSI).

USE EXTREME CAUTION WHEN INSPECTING FOR

HIGH-PRESSURE FUEL LEAKS. FUEL UNDER THIS

AMOUNT OF PRESSURE CAN PENETRATE SKIN

CAUSING PERSONAL INJURY OR DEATH. INSPECT

FOR HIGH-PRESSURE LEAKS WITH A SHEET OF

CARD BOARD. WEAR SAFETY GOGGLES AND

ADEQUATE PROTECTIVE CLOTHING WHEN SER-

VICING FUEL SYSTEM.

WARNING: NO SPARKS, OPEN FLAMES OR SMOK-

ING. RISK OF POISONING FROM INHALING AND

SWALLOWING FUEL. RISK OF INJURY TO EYES

AND SKIN FROM CONTACT WITH FUEL. POUR

FUELS ONLY INTO SUITABLE AND APPROPRI-

ATELY MARKED CONTAINERS. WEAR PROTECTIVE

CLOTHING.

NOTE: Apply a thin film of special grease to the

seals before installing. If the seals are damaged

when being installed, an internal leak may occur

which can not be recognized externally.

(1) Position fuel pressure solenoid to fuel rail and

retain with screws (Fig. 16). Tighten in two stages,

3N·m (26 lbs. in.) then 5N·m (44 lbs. ft.).

(2) Install fuel rail (Refer to 14 - FUEL SYSTEM/

FUEL INJECTION/FUEL INJECTOR - INSTALLA-

TION).

(3) Connect negative battery cable.

Fig. 16 FUEL PRESSURE SOLENOID ASSEMBLY

1 - RETAINING BOLT

2 - FUEL PRESSURE SOLENOID

3 - RETAINING BOLT

4 - O-RING LOCATION

5 - FUEL RAIL

6 - VISE

14 - 28 FUEL INJECTION VA

FUEL PRESSURE SOLENOID (Continued)

Loading...

Loading...