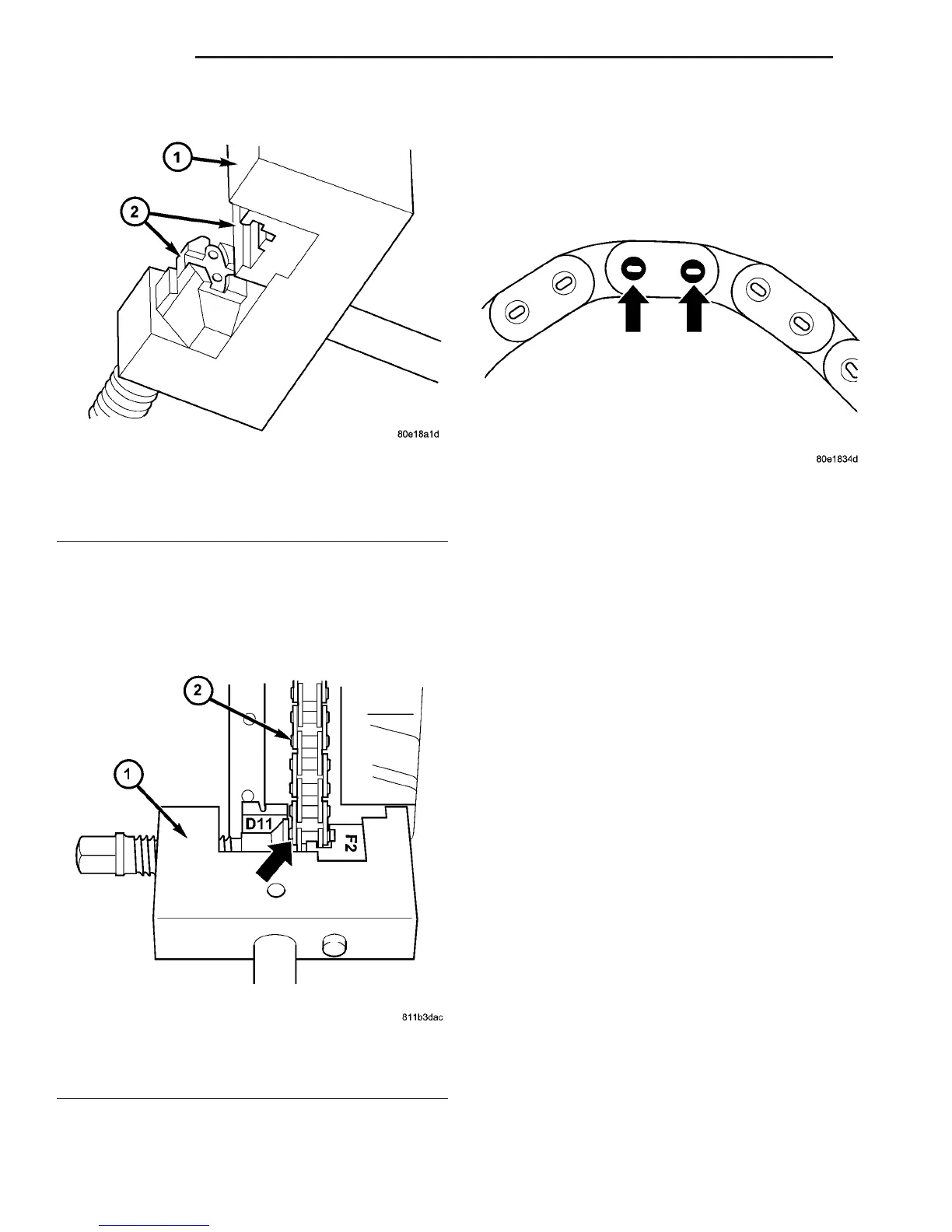

NOTE: Rivet pins of the riveted link individually.

(17) Position riveting tool exactly over middle of

pin (Fig. 60).

(18) Tighten riveting tool spindle until it stops.

(19) Remove riveting tool, inspect riveting, rerivet

if necessary (Fig. 61).

(20) Repeat procedure for both rivets.

(21) Install oil pump (Refer to 9 - ENGINE/LU-

BRICATION/OIL PUMP - INSTALLATION).

(22) Install oil pan (Refer to 9 - ENGINE/LUBRI-

CATION/OIL PAN - INSTALLATION).

(23) Refill engine with proper oil to the correct

level.

(24) Connect negative battery cable.

WARNING: USE EXTREME CAUTION WHEN THE

ENGINE IS OPERATING. DO NOT STAND IN DIRECT

LINE WITH FAN. DO NOT PUT YOUR HANDS NEAR

THE PULLEYS, BELT OR FAN. DO NOT WEAR

LOOSE CLOTHES.

(25) Start engine and inspect for leaks.

OIL TEMPERATURE SENSOR

DESCRIPTION

Oil level, oil temperature and oil quality are

detected by means of an oil sensor located in the oil

pan. The sensor which operates on the capacitance

principle features an integrated electronic circuit

which analyzes the three signals. the signals are con-

stantly relayed to the ECM and over the CAN bus to

the instrument cluster by means of PWM signal.

OPERATION

Oil quality is detected for indicating the need-

based oil change interval. The oil quality is detected

on the basis of the capacitance of the engine oil

(dielectrics, does not conduct electricity), this being

as much as six times greater in case of poor quality.

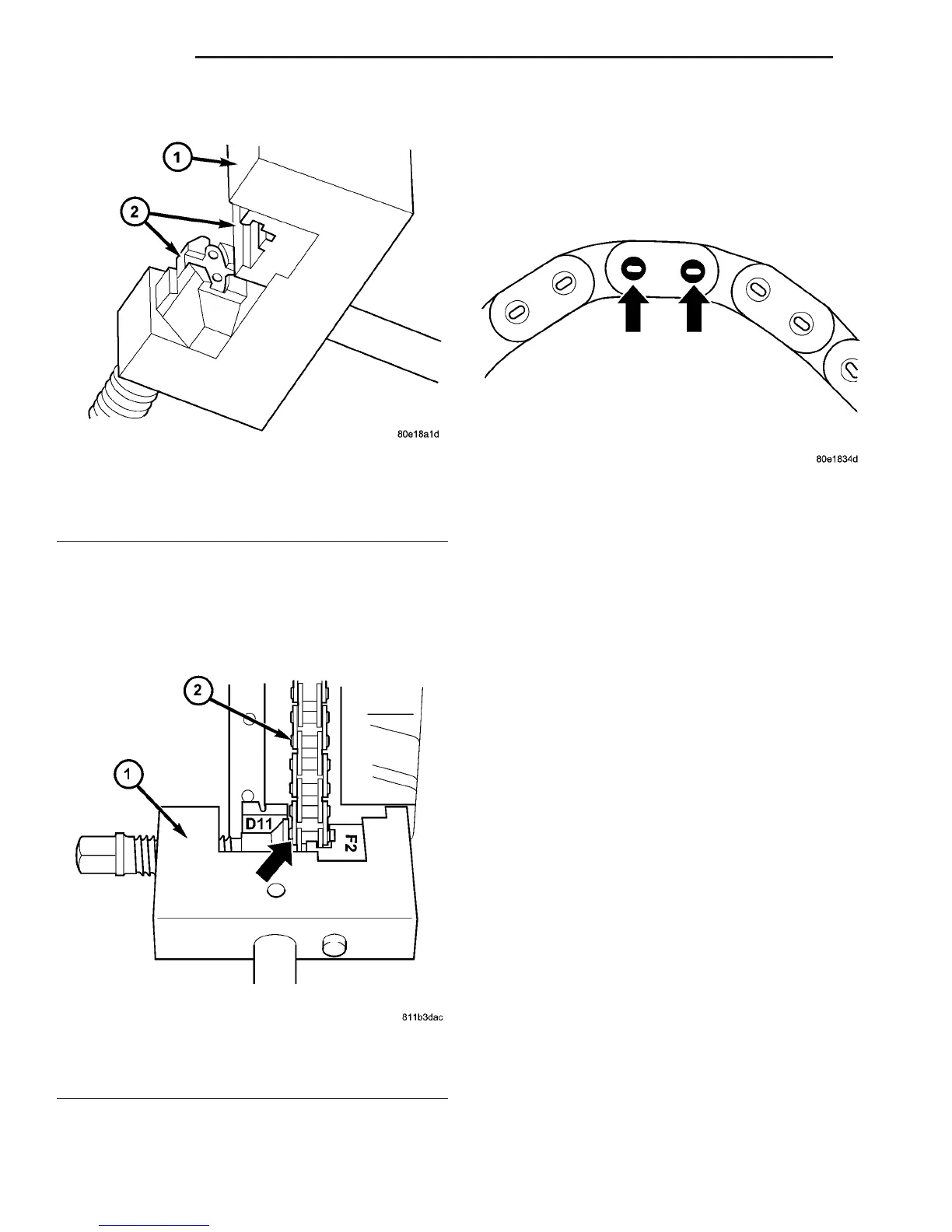

Fig. 59 INSTALLING RIVETING INSERTS INTO

RIVETING TOOL

1 - SPECIAL TOOL #8947

2 - SPECIAL TOOL #9310

Fig. 60 NEW LINK RIVETING

1 - SPECIAL TOOL #8947

2 - OIL PUMP CHAIN

Fig. 61 RIVET INSPECTION

9 - 56 ENGINE VA

OIL PUMP (Continued)

Loading...

Loading...