Starting System Diagnosis

CONDITION POSSIBLE CAUSE CORRECTION

STARTER DOES NOT

DISENGAGE.

1. Starter motor

improperly installed.

1. Refer to Starter Motor Removal and Installation.

Tighten starter mounting hardware to correct torque

specifications.

2. Starter relay faulty. 2. Refer to Starter Relay Diagnosis and Testing. Replace

starter relay if required.

3. Ignition switch faulty. 3. Refer to Ignition Switch and Key Lock Cylinder.

Replace ignition switch if required.

4. Starter motor faulty. 4. If all other starting system components and circuits test

OK, replace starter motor.

INSPECTION

For complete starter wiring circuit diagrams, refer

to 8, Wiring Diagrams. Before removing any unit

from starting system for repair or diagnosis, perform

the following inspections:

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO 8, PASSIVE RESTRAINT SYS-

TEMS, BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, OR INSTRUMENT

PANEL COMPONENT DIAGNOSIS OR SERVICE.

FAILURE TO TAKE THE PROPER PRECAUTIONS

COULD RESULT IN ACCIDENTAL AIRBAG DEPLOY-

MENT AND POSSIBLE PERSONAL INJURY.

• Battery - Visually inspect battery for indica-

tions of physical damage and loose or corroded cable

connections. Determine state-of-charge and cranking

capacity of battery. Charge or replace battery if

required. Refer to Battery in 8, Battery.

• Ignition Switch - Visually inspect ignition

switch for indications of physical damage and loose

or corroded wire harness connections. Refer to Igni-

tion Switch and Key Lock Cylinder.

• Park/Neutral Position Switch - Visually

inspect park/neutral position switch for indications of

physical damage and loose or corroded wire harness

connections. Refer to Park/Neutral Position

Switch in 21, Transmission.

• Starter Relay - Visually inspect starter relay

for indications of physical damage and loose or cor-

roded wire harness connections.

• Starter Motor - Visually inspect starter motor

for indications of physical damage and loose or cor-

roded wire harness connections.

• Starter Solenoid - Visually inspect starter sole-

noid for indications of physical damage and loose or

corroded wire harness connections.

• Wiring - Visually inspect wire harnesses for

damage or corrosion. Repair or replace any faulty

wiring, as required. Refer to 8, Wiring Diagrams.

TESTING

COLD CRANKING TEST

For complete starter wiring circuit diagrams, refer

to 8, Wiring Diagrams. The battery must be fully-

charged and load-tested before proceeding. Refer to

Battery in 8, Battery.

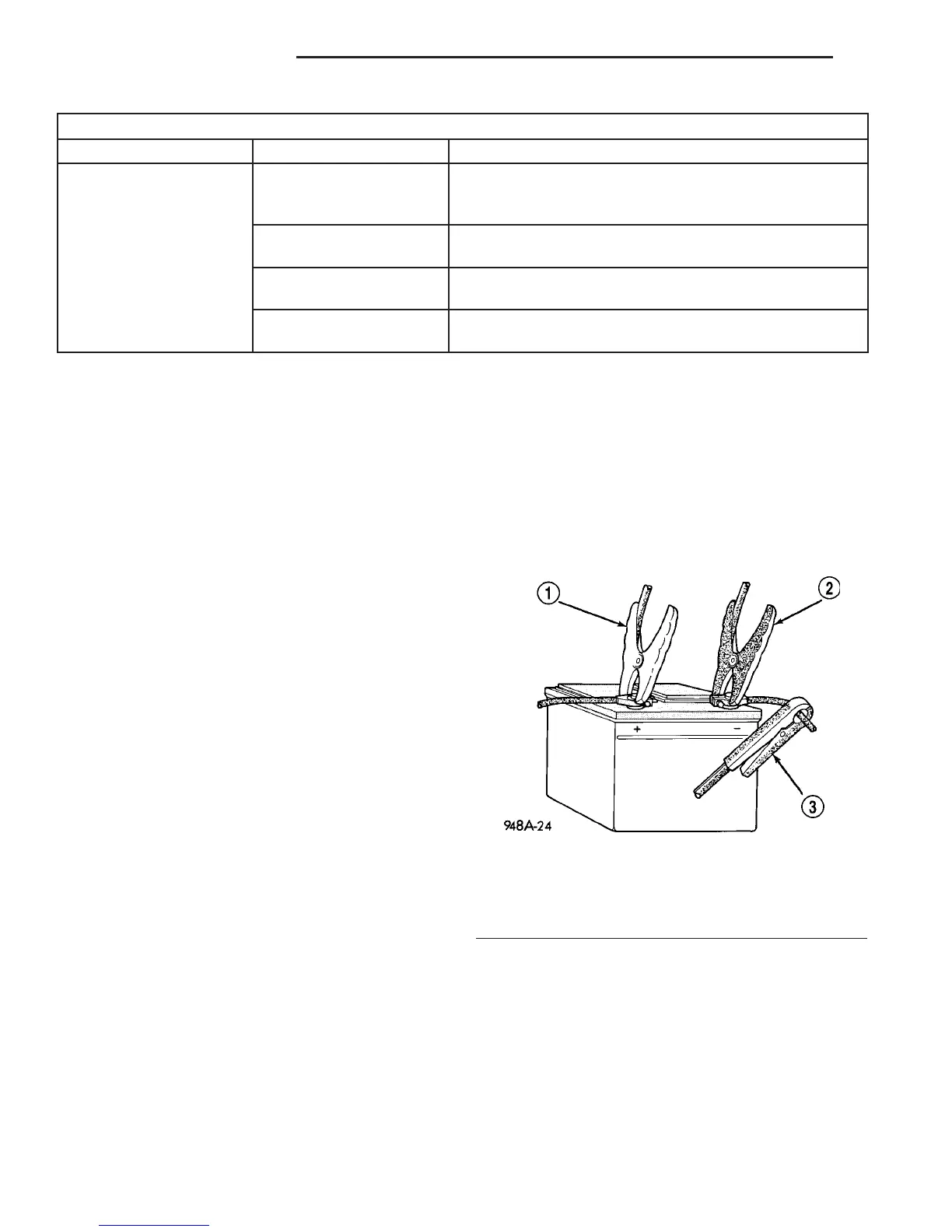

(1) Connect volt-ampere tester to battery terminals

(Fig. 1). See instructions provided by manufacturer of

volt-ampere tester being used.

(2) Fully engage parking brake.

(3) Place gearshift selector lever in Park position.

(4) Verify that all lamps and accessories are

turned off.

(5) To prevent engine from starting, remove Fuel

Pump Relay. This relay is located in Power Distribu-

tion Center (PDC). Refer to label on PDC cover for

relay location.

Fig. 1 VOLTS-AMPS TESTER CONNECTIONS -

TYPICAL

1 - POSITIVE CLAMP

2 - NEGATIVE CLAMP

3 - INDUCTION AMMETER CLAMP

8F - 26 STARTING SYSTEM VA

STARTING SYSTEM (Continued)

Loading...

Loading...