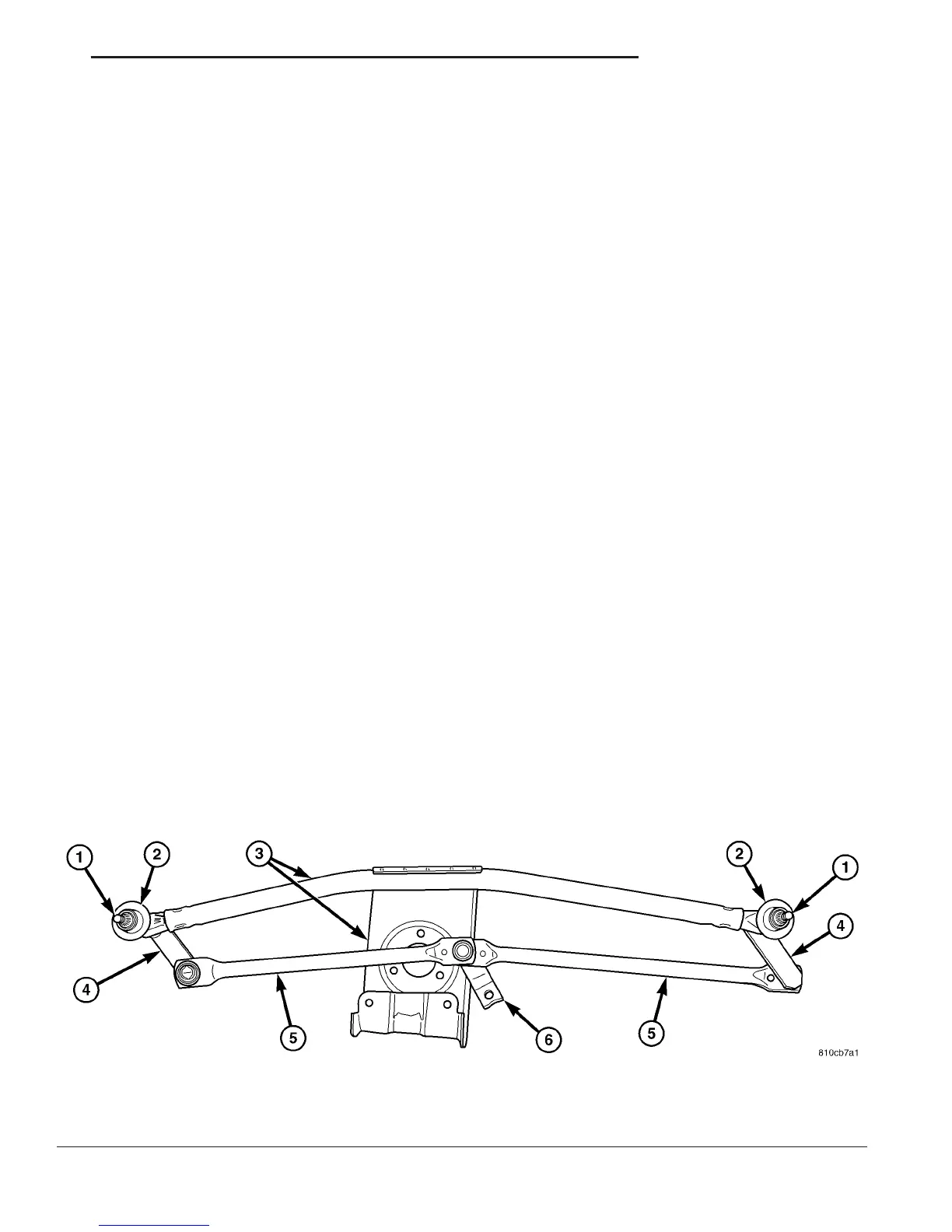

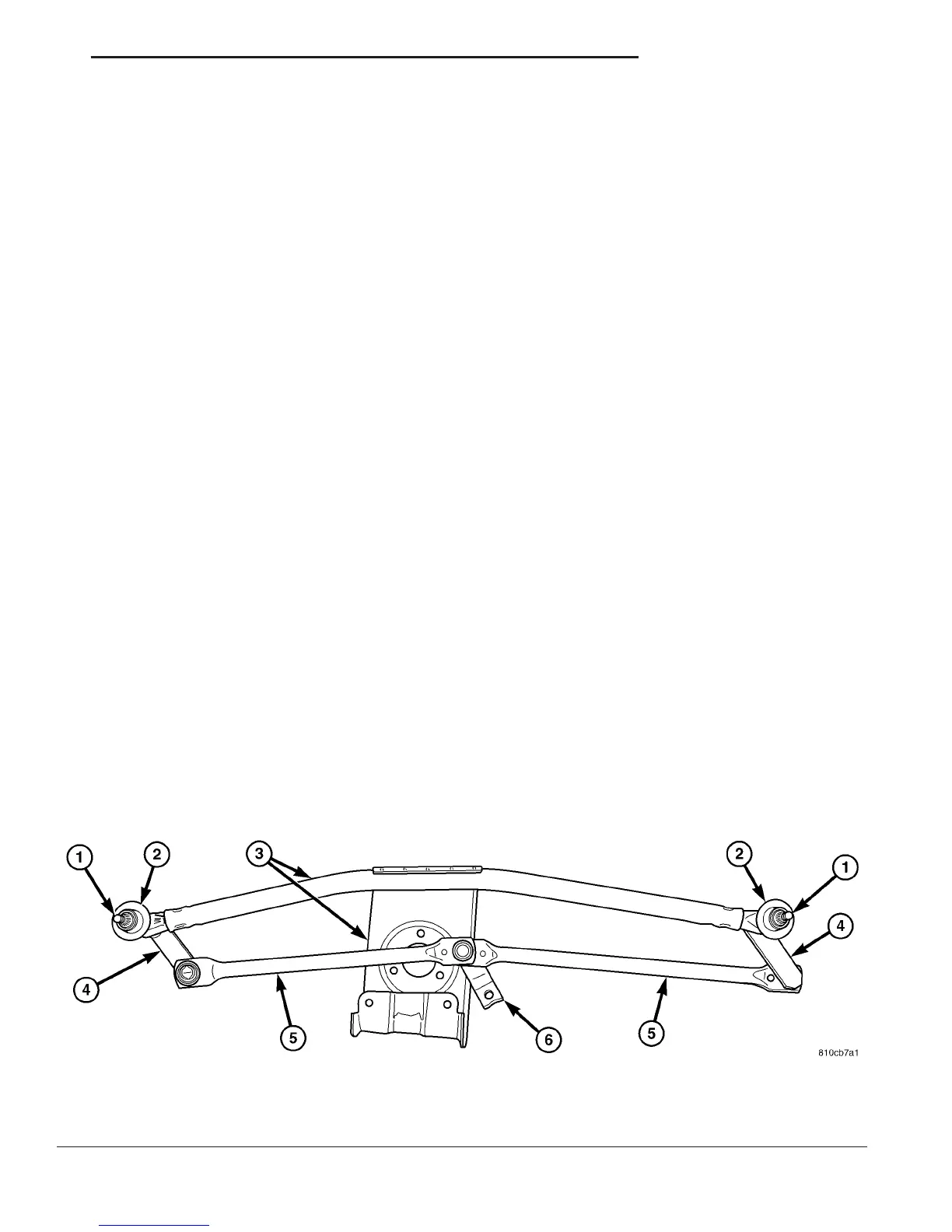

WIPER LINKAGE

DESCRIPTION

The wiper linkage and pivots are concealed within

the engine compartment below the cowl top panel

(Fig. 20). The ends of the wiper pivot shafts that pro-

trude through dedicated openings in the cowl top

panel to drive the wiper arms and blades are the

only visible components of the wiper linkage module.

The wiper linkage module consists of the following

major components:

• Linkage - The two wiper drive links are each

constructed of stamped steel. The left (driver) side

drive link has a plastic socket-type bushing in one

end, and a plastic sleeve-type bushing in the other

end. The socket bushing is snap-fit over the ball stud

on the left pivot crank arm, while the sleeve bushing

is fit over the longer ball stud on the wiper motor

crank arm. The right (passenger) side drive link has

a plastic socket-type bushing on each end. One end of

this drive link is snap-fit over the exposed end of the

longer ball stud on the wiper motor crank arm and

captures the sleeve bushing end of the left drive link

beneath it, while the other end is snap-fit over the

ball stud on the right pivot crank arm.

• Module Bracket - The linkage module bracket

consists of a long tubular steel main member that is

crimped to a molded plastic pivot bracket at each end

where the wiper pivots are secured. A stamped steel

mounting plate for the wiper motor is secured with

welds near the center of the main member and is

then secured with screws to the underside of the cowl

top panel.

• Motor Crank Arm - The wiper motor crank

arm is a stamped steel unit with a round hole on the

driven end that is secured to the wiper motor output

shaft with a nut, and a long ball stud secured to the

drive end.

• Pivot - The two molded plastic wiper pivot

brackets are secured to the ends of the linkage mod-

ule bracket tubular member. The crank arms that

extend from the bottom of the pivot shafts each have

a ball stud on their end. The upper end of each pivot

shaft where the wiper arms will be fastened each is

tapered and externally serrated with a threaded stud

at the top where the wiper arms are secured by a

nut. Each pivot shaft operates within a housing

formed in the pivot bracket featuring a large external

flange near its center and external threads near the

top. The pivot housings are secured to the outer sur-

face of the cowl top panel by a large washer and a

nut threaded onto the outside of the housing where it

protrudes through the cowl top.

The wiper linkage module cannot be adjusted or

repaired. If any component of the linkage module is

faulty or damaged, the entire wiper linkage module

unit must be replaced.

OPERATION

The wiper linkage operation is controlled by the

output of the wiper motor through the wiper motor

crank arm. The wiper motor crank arm, the two

wiper drive links, and the two wiper pivots mechan-

ically convert the rotary output of the wiper motor to

the back and forth wiping motion of the wiper arms

and blades on the glass.

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the wiper arms from the wiper pivots.

(Refer to 8 - ELECTRICAL/WIPERS/WASHERS/

WIPER ARM - REMOVAL).

Fig. 20 Wiper Linkage Module

1 - PIVOT SHAFT (2) 4 - PIVOT CRANK ARM (2)

2 - PIVOT SHAFT HOUSING (2) 5 - DRIVE LINK (2)

3 - MODULE BRACKET 6 - MOTOR CRANK ARM

VA WIPERS/WASHERS 8R - 17

Loading...

Loading...