SHIFT GROUPS

The hydraulic control components (including actua-

tors) which are responsible for the pressure distribu-

tion before, during, and after a gear change are

described as a shift group. Each shift group contains

a command valve, a holding pressure shift valve, a

shift pressure shift valve, overlap regulating valve,

and a solenoid.

The hydraulic system contains three shift groups:

1-2/4-5, 2-3, and 3-4. Each shift group can also be

described as being in one of two possible states. The

active shift group is described as being in the shift

phase when it is actively engaging/disengaging a

clutch combination. The 1-2/4-5 shift group control

the B1 and K1 clutches. The 2-3 shift group controls

the K2 and K3 clutches. The 3-4 shift group controls

the K3 and B2 clutches.

OPERATION

The transmission control is divided into the elec-

tronic and hydraulic transmission control functions.

While the electronic transmission control is responsi-

ble for gear selection and for matching the pressures

to the torque to be transmitted, the transmission’s

power supply control occurs via hydraulic elements

in the electrohydraulic control module. The oil supply

to the hydraulic elements, such as the hydrodynamic

torque converter, the shift elements and the hydrau-

lic transmission control, is provided by way of an oil

pump connected with the torque converter.

The Transmission Control Module (TCM) allows for

the precise adaptation of pressures to the correspond-

ing operating conditions and to the engine output

during the gearshift phase, resulting in a noticeable

improvement in shift quality. The engine speed limit

can be reached in the individual gears at full throttle

and kickdown. The shift range can be changed in the

forward gears while driving, but the TCM employs a

downshift safeguard to prevent over-revving the

engine. The system offers the additional advantage of

flexible adaptation to different vehicle and engine

variants.

EMERGENCY RUNNING FUNCTION

In order to ensure a safe driving state and to pre-

vent damage to the automatic transmission, the TCM

control module switches to limp-home mode in the

event of critical faults. A DTC assigned to the fault is

stored in memory. All solenoid and regulating valves

are thus de-energized.

The net effect is:

• The last engaged gear remains engaged.

• The modulating pressure and shift pressures

rise to the maximum levels.

• The torque converter lockup clutch is deacti-

vated.

In order to preserve the operability of the vehicle

to some extent, the hydraulic control can be used to

engage 2nd gear or reverse using the following pro-

cedure:

• Stop the vehicle.

• Switch off engine.

• Move selector lever to 9P9.

• Wait at least 10 seconds.

• Start engine.

• Move selector lever to D: 2nd gear.

• Move selector lever to R: Reverse gear.

The limp-home function remains active until the

DTC is rectified or the stored DTC is erased with the

DRBt tool. Sporadic faults can be reset via ignition

OFF/ON.

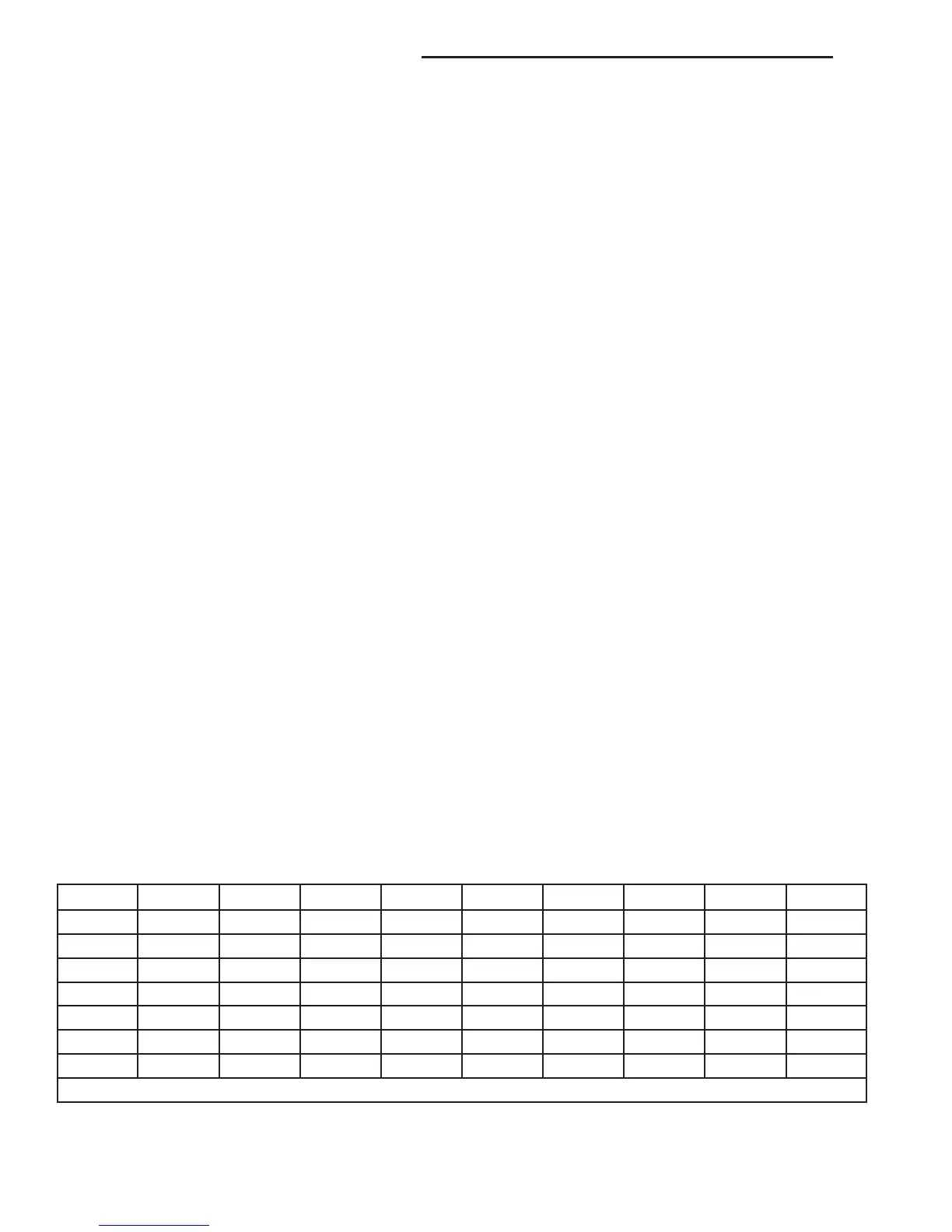

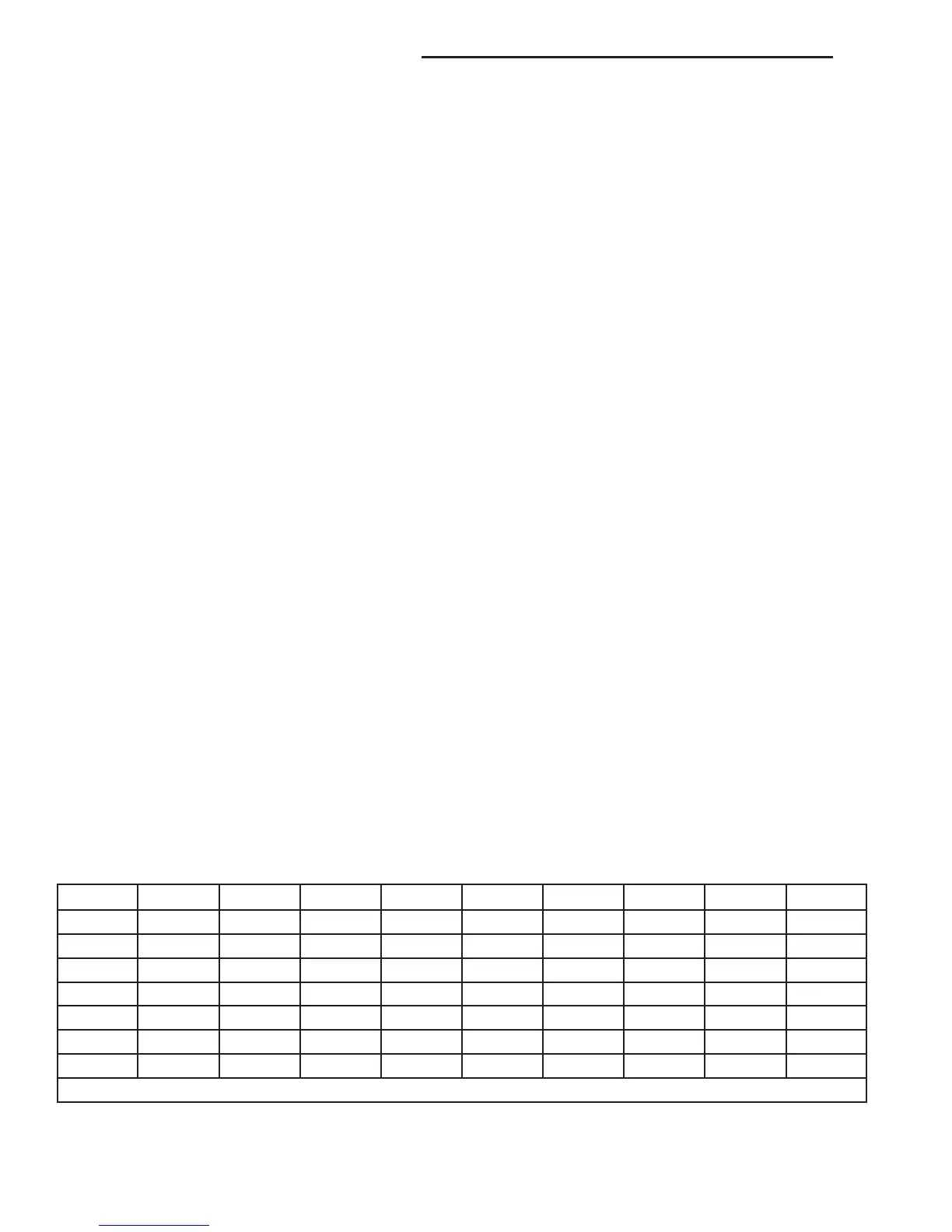

CLUTCH APPLICATION

Refer to CLUTCH APPLICATION for which shift

elements are applied in each gear position.

CLUTCH APPLICATION

GEAR RATIO B1 B2 B3 K1 K2 K3 F1 F2

1 3.59 X* X X* X X

2 2.19 X X X* X

3 1.41 X X X

4 1.00 X X X

5 0.83 X X X X*

NX X

R 3.16 X* X X X

* = The shift components required during coast.

21 - 4 AUTOMATIC TRANSMISSION - NAG1 VA

AUTOMATIC TRANSMISSION - NAG1 (Continued)

Loading...

Loading...