(3) Unplug electrical connector at high pressure

pump.

CAUTION: DO NOT slacken the threaded connec-

tion. Use a wrench to counterhold at the threaded

connection when loosening and tightening the

union nut. DO NOT EXCEED tightening torque.

CAUTION: DO NOT crimp or bend fuel line. Capture

all fluids that flow out of connections.

NOTE: Using a marking pen, make a mark on the

outside fuel return line to easily identify proper

position during assembly.

(4) Unbolt bracket and pressure line at pressure

pump.

(5) Detach fuel supply and return flow line at high

pressure pump.

NOTE: Care must be taken not to drop the high

pressure pump driver and intermediate piece if

pump is being replaced.

(6) Remove bolts attaching high pressure pump

and remove pump.

REMOVAL - LOW PRESSURE PUMP

WARNING: NO SPARKS, OPEN FLAMES OR SMOK-

ING. RISK OF POISONING FROM INHALING AND

SWALLOWING FUEL. RISK OF INJURY TO EYES

AND SKIN FROM CONTACT WITH FUEL. POUR

FUELS ONLY INTO SUITABLE AND APPROPRI-

ATELY MARKED CONTAINERS. WEAR PROTECTIVE

CLOTHING.

(1) Disconnect negative battery cable.

(2) Remove vacuum pump (Refer to 9 - ENGINE/

ENGINE BLOCK/INTERNAL VACUUM PUMP -

REMOVAL).

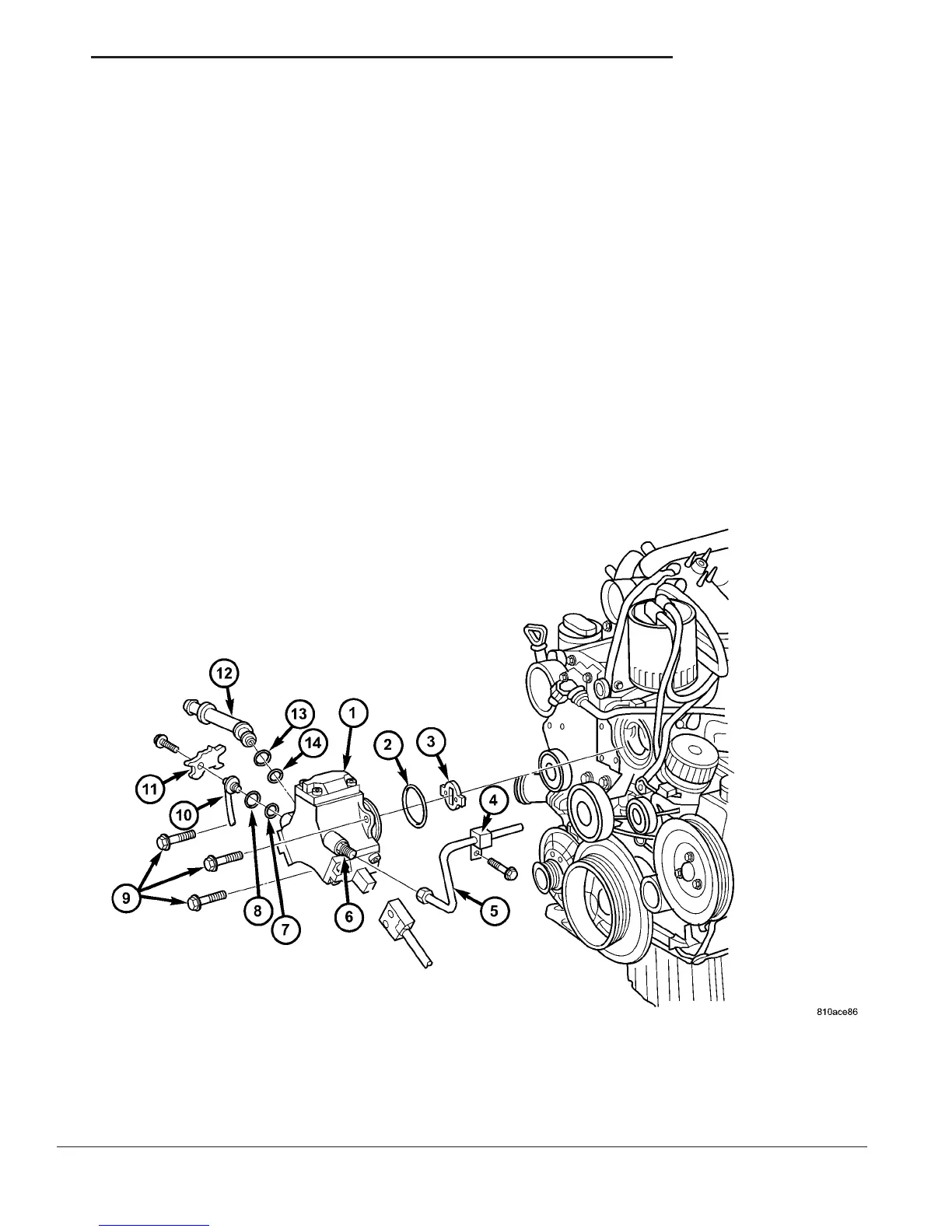

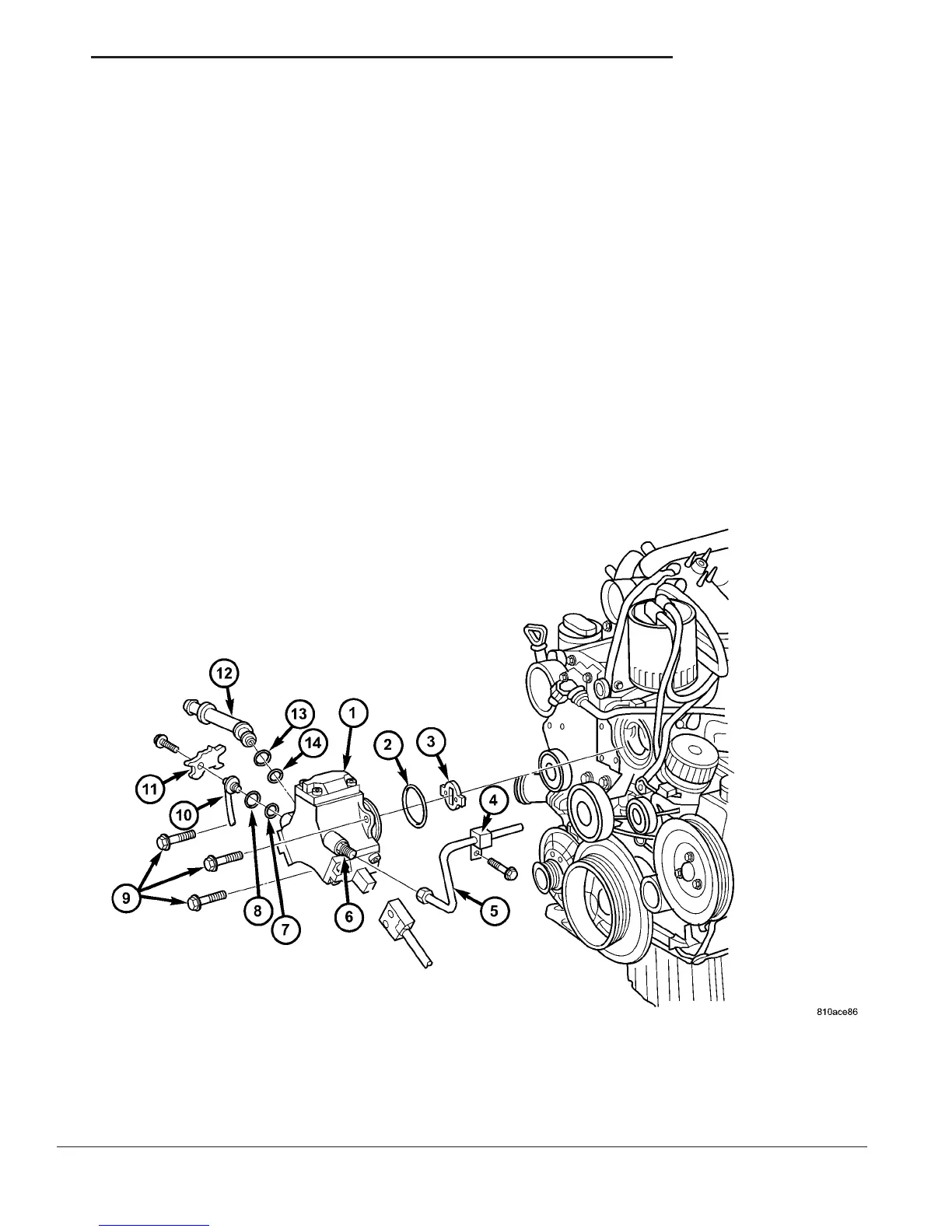

Fig. 5 HIGH PRESSURE PUMP

1 - HIGH PRESSURE INJECTION PUMP 8 - SEALING RING

2 - SEALING RING 9 - BOLTS

3 - INJECTION PUMP DRIVER 10 - FUEL RETURN LINE

4 - BRACKET 11 - BRACKET

5 - HIGH PRESSURE LINE 12 - FUEL SUPPLY LINE FROM LOW PRESSURE PUMP

6 - THREADED UNION 13 - SEALING RING

7 - SEALING RING 14 - SEALING RING

VA FUEL DELIVERY 14 - 9

FUEL PUMP (Continued)

Loading...

Loading...