(5) Carefully raise locking pawl of top slide rail

and remove front cover at cylinder head (Fig. 15).

(6) Insert a locking pin through 1st camshaft bear-

ing cap into the hole in the inlet camshaft sprocket.

(7) Counter hold the camshaft with an open end

wrench to avoid damage and unbolt driver of inlet

camshaft sprocket.

(8) Remove top guide rail.

INSTALLATION

INSTALLATION - CYLINDER HEAD

WARNING: (Refer to 14 - FUEL SYSTEM - WARN-

ING)

NOTE: Thoroughly clean all mating surfaces with

appropriate solvents and blow out bolt holes, to

assure that no grease or oil is present during reas-

sembly.

NOTE: If piston or connecting rods have been

replaced, measure piston protrusion.

NOTE: Check facing cylinder head contact surface.

(1) Position the cylinder head and gasket properly

on engine using the dowel pins as guide (Fig. 14).

NOTE: Inspect all cylinder head bolts for defects

and stretching before installation (Refer to 9 -

ENGINE/CYLINDER HEAD - STANDARD PROCE-

DURE).

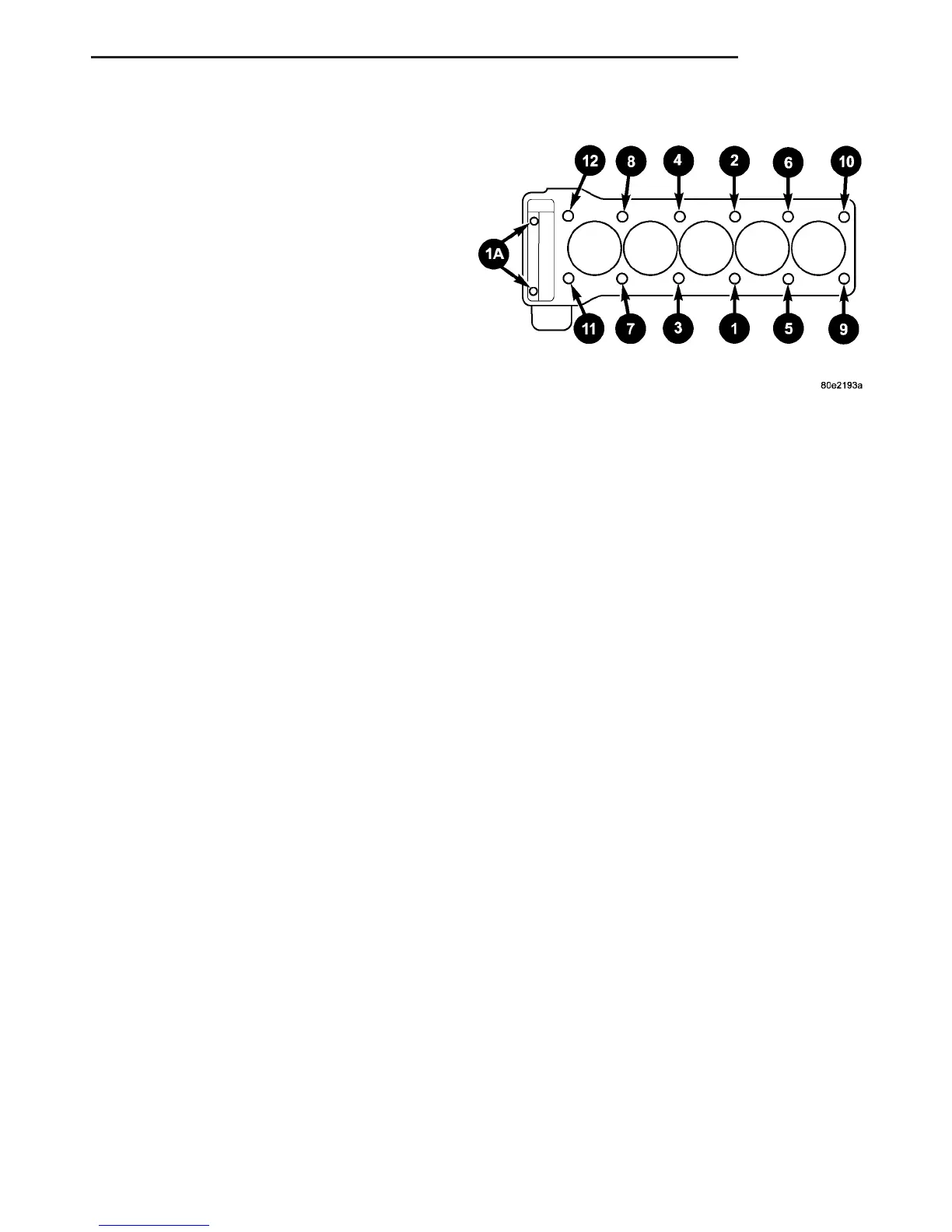

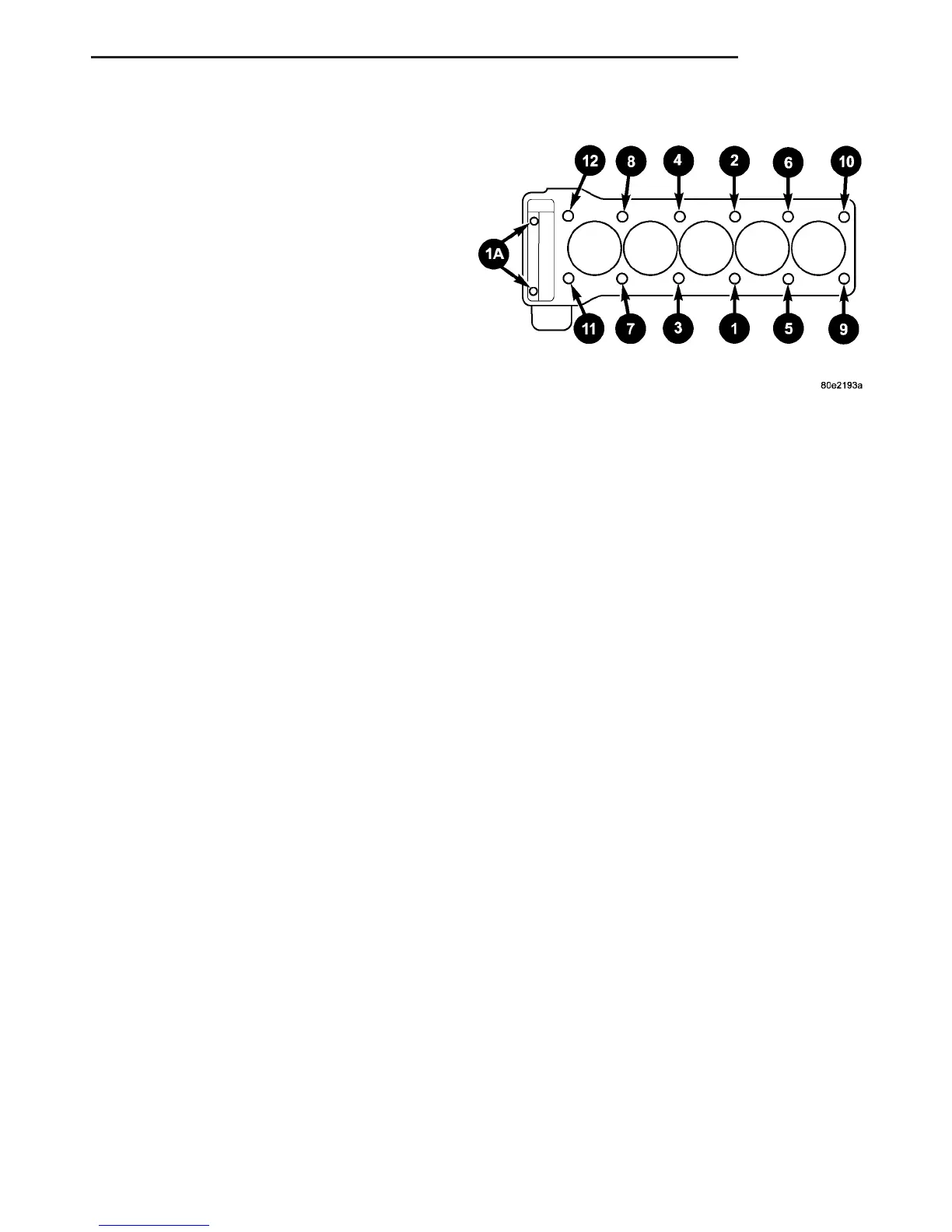

CYLINDER HEAD BOLT TORQUE SEQUENCE

The M12 cylinder head bolts must be torqued

in 3 stages.

(1) Install M12 cylinder head bolts finger tight

(Fig. 14).

(2) Torque bolts in numeric order starting with

number 1 to 60 N·m (44 lbs.in.) (Fig. 16).

(3) Install M8 timing chain cover to cylinder head

bolts. Tighten to 20N·m (177 lbs.in.).

(4) Tighten M12 cylinder head bolts in numeric

order starting with number 1 an additional 90° (Fig.

16).

(5) Tighten M12 cylinder head bolts in numeric

order starting with number 1 an additional 90° again

(3 stages). (Fig. 16).

(2) Install fuel return flow line between rail and

high pressure pump (Fig. 13).

(3) Connect the coolant hoses to the thermostat

housing (Fig. 13).

(4) Connect the coolant pipe at the cylinder head

(Fig. 13).

(5) Reconnect transmission oil dip stick tube.

Tighten to 14 N·m (124 lbs. in.) (Fig. 13).

(6) Reconnect the turbocharger to the exhaust

manifold. Tighten to 30N·m (22 lbs.ft.) (Fig. 13).

(7) Install oil return flow line with new seals at

turbocharger. Tighten bolt of supply line to turbo-

charger to 18N·m (160 lbs. in.) and bolt of supply line

to cylinder head to 9N·m (80 lbs. in.) (Fig. 13)

(8) Install charge air distribution pipe (Refer to 11

- EXHAUST SYSTEM/TURBOCHARGER SYSTEM -

INSTALLATION).

(9) Install and properly route the engine wiring

harness, making appropriate connections.

(10) Install high pressure fuel pump intermediate

gear (Fig. 13).

(11) Install high pressure pump (Refer to 14 -

FUEL SYSTEM/FUEL DELIVERY/FUEL INJEC-

TION PUMP - INSTALLATION).

(12) Install the camshaft housing to cylinder head

(Fig. 13).

(13) Install the tappets (Fig. 13).

(14) Install camshafts (Refer to 9 - ENGINE/CYL-

INDER HEAD/CAMSHAFT(S) - INSTALLATION).

(15) Install top guide rail (Refer to 9 - ENGINE/

VALVE TIMING/TIMING BELT/CHAIN AND

SPROCKETS - INSTALLATION).

(16) Install front cover at cylinder head (Refer to 9

- ENGINE/CYLINDER HEAD - INSTALLATION).

(17) Install cylinder head cover (Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - INSTALLATION).

(18) Install fuel high pressure pipes and injectors

(Refer to 14 - FUEL SYSTEM/FUEL INJECTION/

FUEL INJECTOR - INSTALLATION).

(19) Install timing chain tensioner with new gas-

ket. (Refer to 9 - ENGINE/VALVE TIMING/TIMING

Fig. 16 CYLINDER HEAD BOLT TORQUE

SEQUENCE

VA ENGINE 9 - 25

CYLINDER HEAD (Continued)

Loading...

Loading...