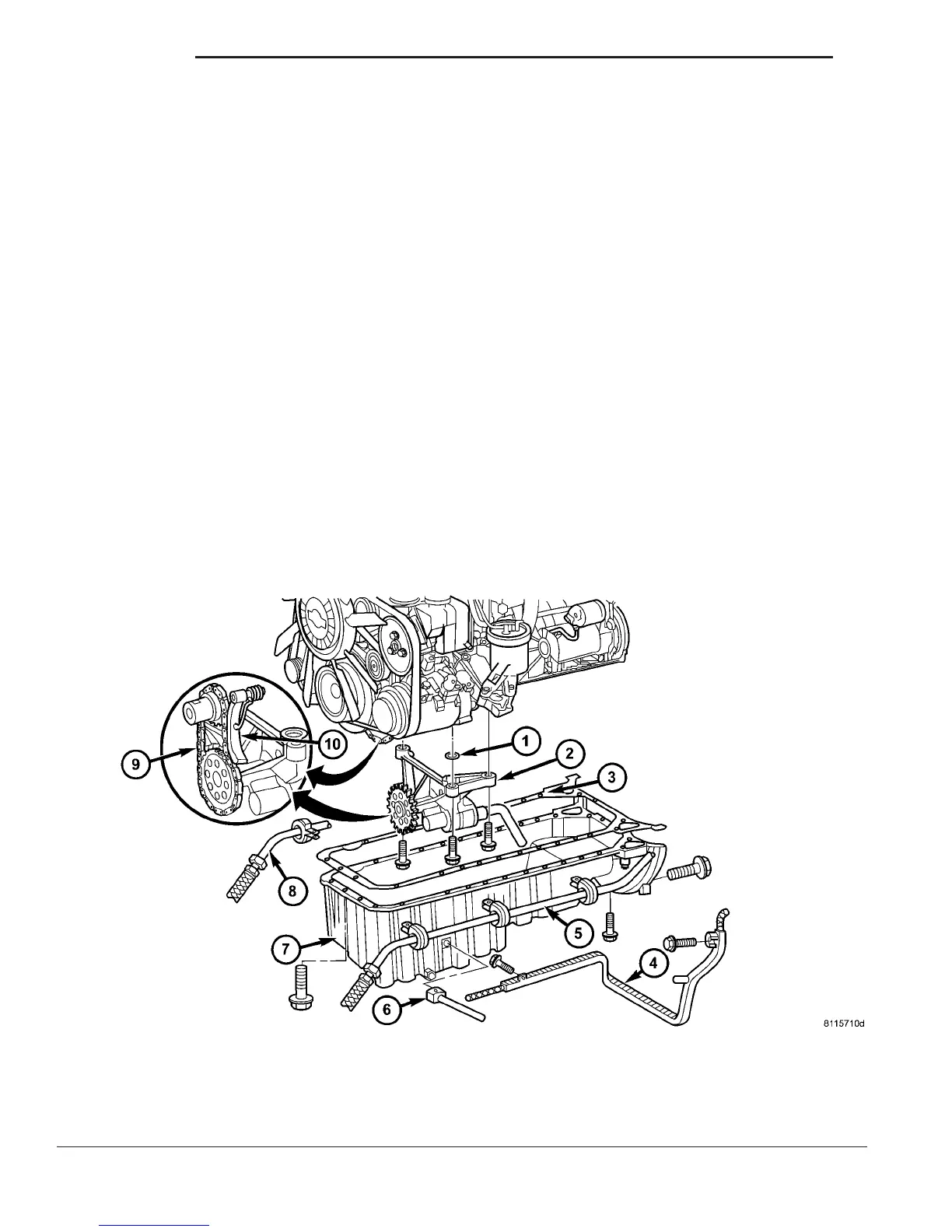

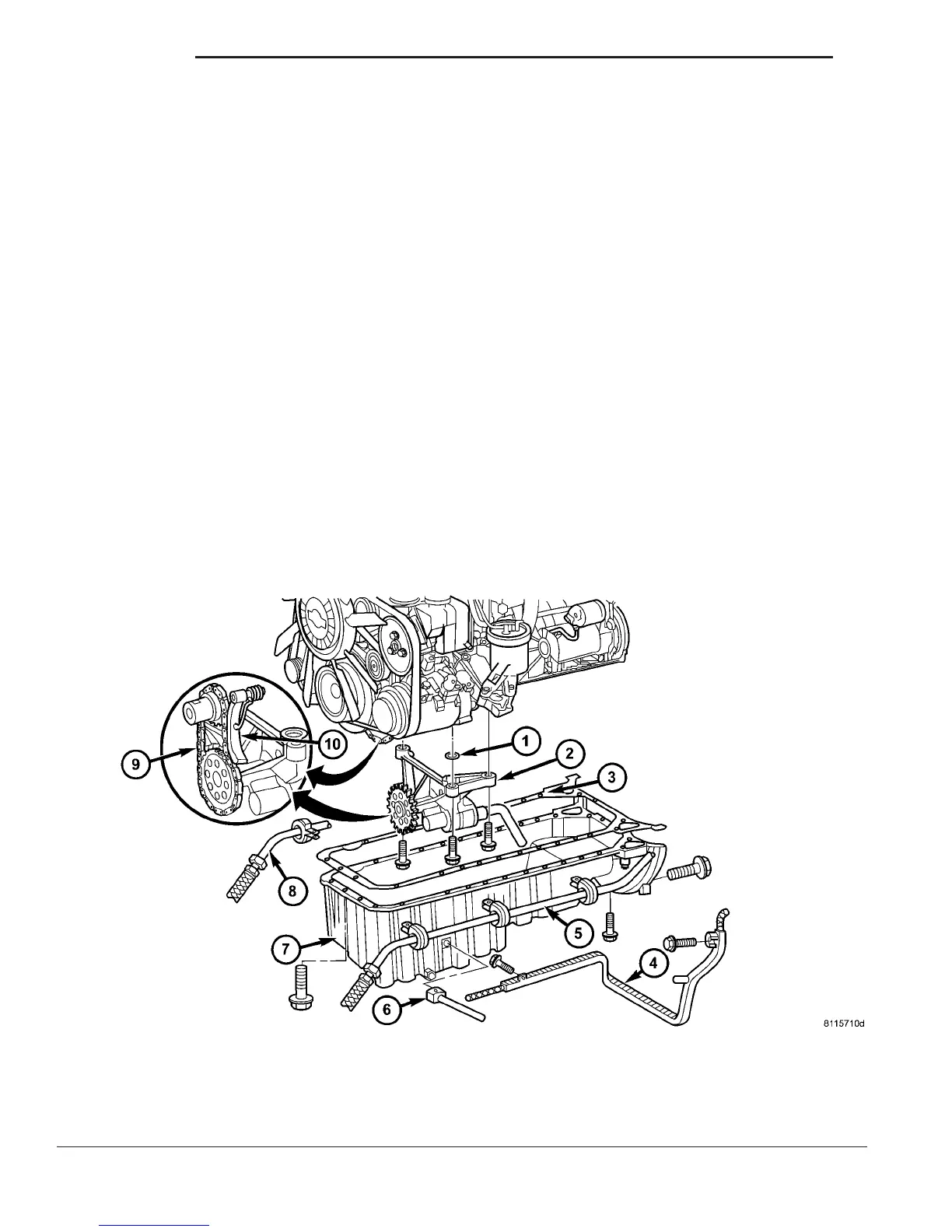

OIL PAN

REMOVAL

(1) Drain engine oil.

(2) Remove the sway bar retaining bolts and swing

sway bar down and out of the way.

(3) Remove the wiring harness duct from the oil

pan bolts and position out of the way.

(4) Lower the vehicle and remove the turbocharger

upper heat shield.

(5) Connect engine support fixture #8534 using

adaptors #8534–16, to the engine lifting eye and

raise engine slightly.

(6) Remove engine mounts and raise engine.

(7) Disconnect the oil level sensor.

(8) Remove the transmission cooler lines from the

oil pan bolts and carefully position the lines aside

(9) Remove the oil pan bolts.

(10) Remove oil pan and gasket (Fig. 51).

INSTALLATION

NOTE: Oil pan bolts are of different diameters and

lengths. Care must be take to install the bolts in

their original position (Fig. 53).

NOTE: Clean the strainer of the oil pump. If the oil

pump is dry, fill it with clean engine oil.

NOTE: Thoroughly clean all mating surfaces with

the appropriate solvents to assure that no grease or

oil is present during reassembly.

(1) Install the oil pan gasket and coat places indi-

cated with an arrow with sealant (Fig. 52).

(2) Install the oil pan. Tighten M6 bolts to 9N·m

(80 lbs. in.) and M8 bolts to 20N·m (15 lbs. ft.) (Fig.

53).

Fig. 51 OIL PAN

1 - O-RING 6 - CONNECTOR FOR OIL LEVEL SENSOR

2 - OIL PUMP 7 - OIL PAN

3 - GASKET 8 - TRANSMISSION LINE

4 - WIRING HARNESS DUCT 9 - OIL PUMP CHAIN

5 - TRANSMISSION LINE 10 - OIL PUMP CHAIN TENSIONER

9 - 52 ENGINE VA

Loading...

Loading...