7. Check ignition sparks while the letting the en-

gine run with the starter motor.

8. Remove the spark plug.

- IF THERE ARE NO SPARKS, CHECK FOR POWER SUP-

PLY. - BEFORE CARRYING OUT THIS OPERATION,

CHECK FOR FUEL LEAKS INSIDE THE ENGINE COM-

PARTMENT. CLEAN THE FUEL LEAK, IF NECESSARY.

WORK IN A WELL VENTILATED AREA PAYING ATTEN-

TION THAT THERE ARE NO VOLATILE LIQUIDS, GAS,

ETC. NEARBY.

9. Spark plug cleaning.

N.B.

- REMOVE ANY OIL TRACES WITH PETROL BEFORE

CLEANING THE SPARK PLUG WITH THE APPROPRIATE

CLEANING DEVICE.

- IF THERE IS HUMID CARBON ON THE ELECTRODE, DRY

THE ELECTRODE AND CLEAN IT WITH THE APPROPRI-

ATE CLEANING DEVICE.

AIR PRESSURE:

IT MUST NOT EXCEED 588 KPA. DURATION: LESS THAN

20 SECONDS

10. Visually inspect the spark plug, checking that

the electrode is not worn and that the thread or

insulator is not damaged.

11. Check of distance between the electrodes.

Measure the distance between the electrodes with

a thickness gauge.

IF NECESSARY, REPLACE THE SPARK PLUG.

N.B.

- IF THE DISTANCE BETWEEN THE ELECTRODES DOES

NOT COMPLY TO THE SPECIFIED VALUES, ADJUST

BENDING THE EARTH ELECTRODE BASE PAYING AT-

TENTION NOT TO TOUCH THE FACE.

- THE FOUR SPARK PLUGS MUST BE AT THE SAME HEAT

RATING AND BELONGING TO THE SAME BRAND.

Characteristic

Electrode gap

0.9 - 1.0 mm

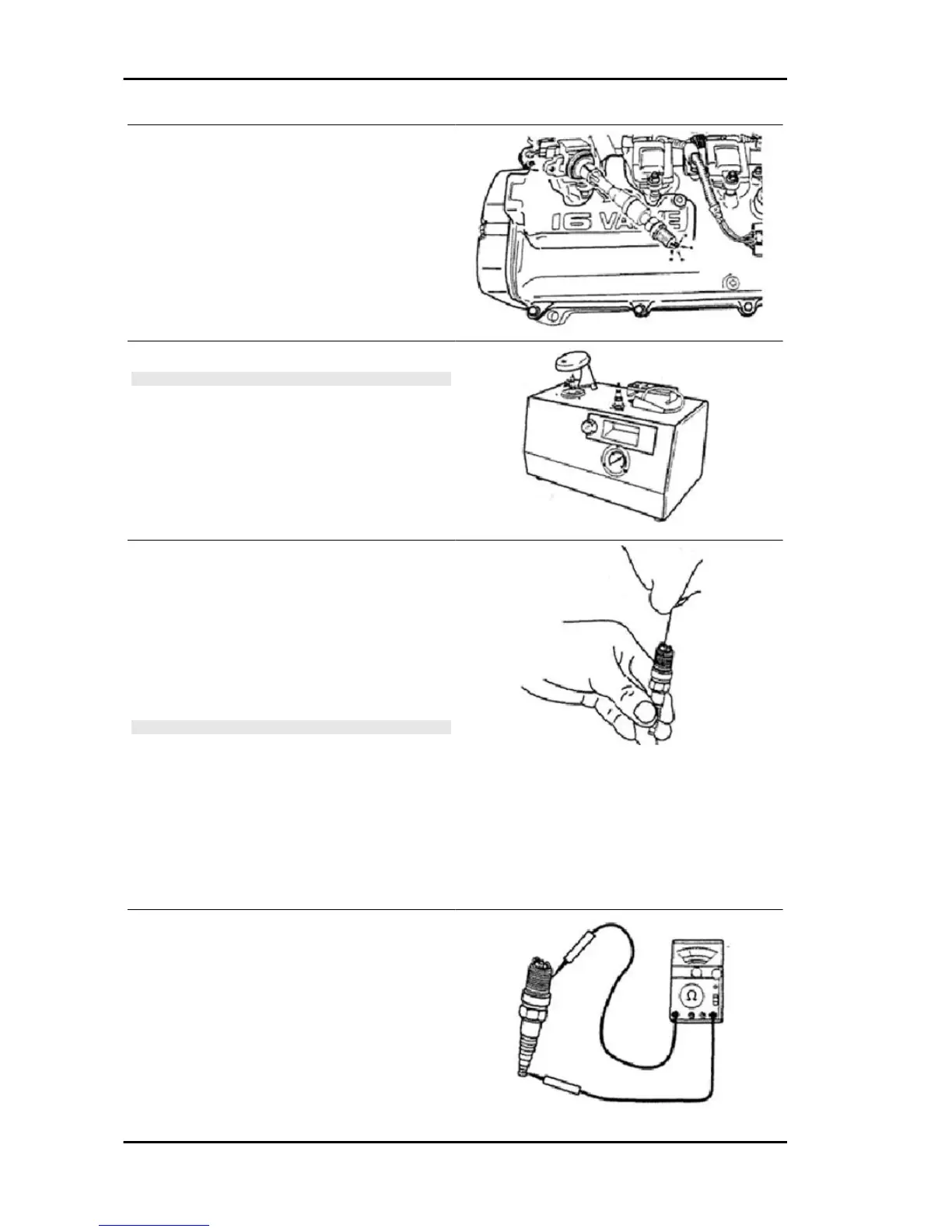

12. Checking spark plug insulation resistance to a

value higher than 20 MΩ

- IF THE INSULATION RESISTANCE IS BELOW THE SPECI-

FIED VALUE, REPLACE THE SPARK PLUG.

Electrical system PORTER 1.3 16V

ES - 164

Loading...

Loading...